Linear Actuator

A linear transmission and linear slide technology, applied in transmission devices, measuring devices, instruments, etc., can solve the problems of poor conduction efficiency, time-consuming and laborious, and poor measurement efficiency, and achieve the effect of reducing the inaccuracy of measurement signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The technical solutions of the present invention will be described clearly and completely below. Obviously, the described embodiments are a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work fall within the protection scope of the present invention.

[0066] Before presenting the detailed description, it is to be noted that in the following description, similar components are denoted by the same numerals.

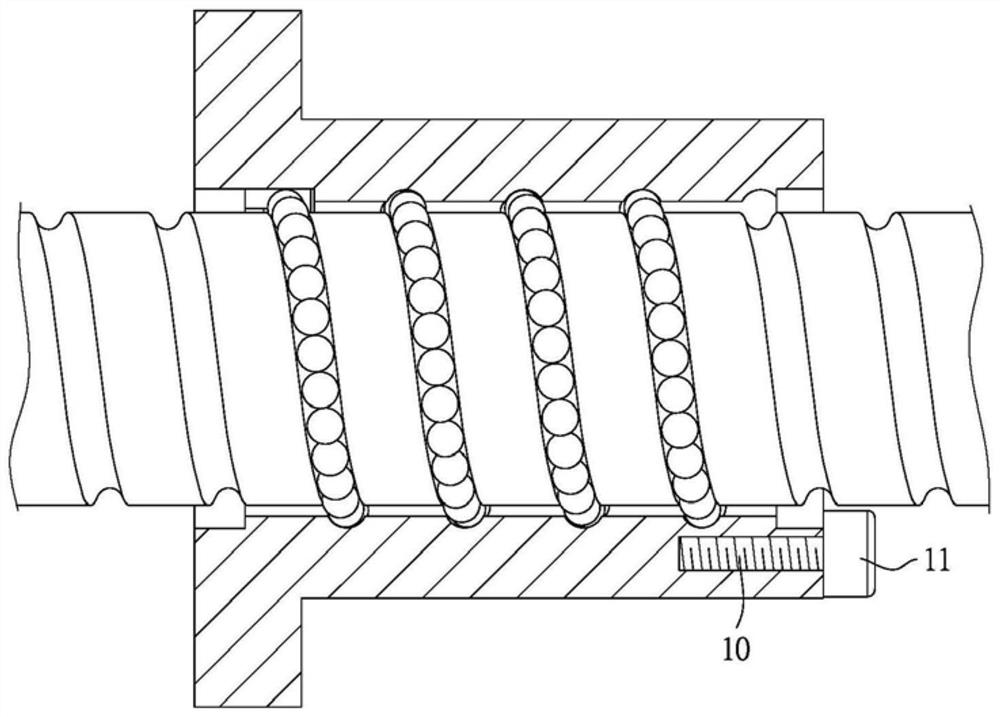

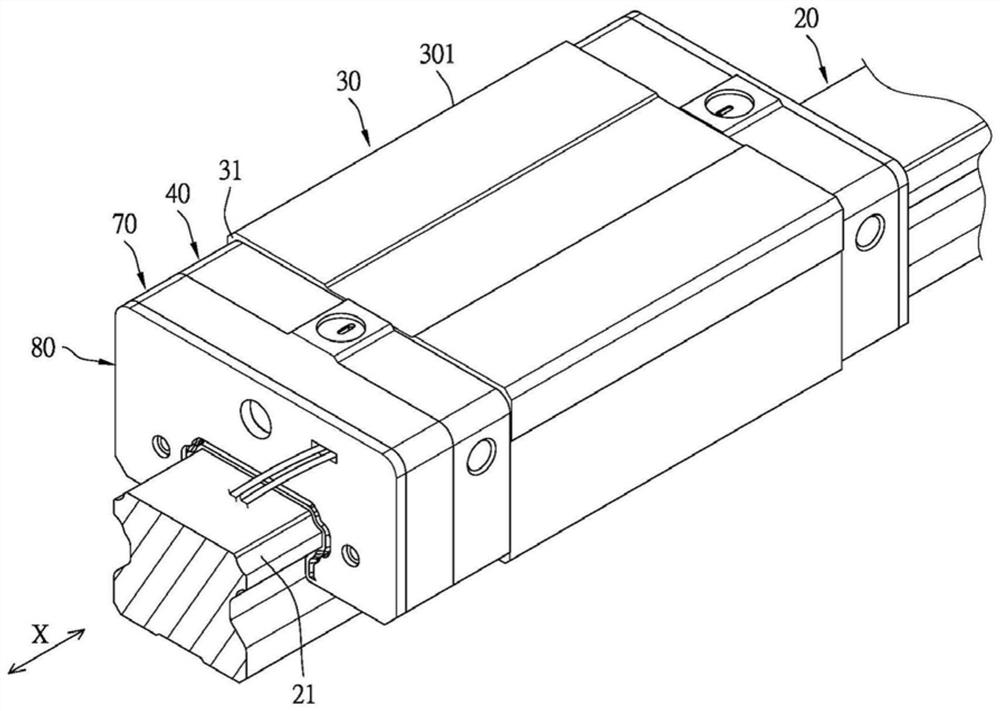

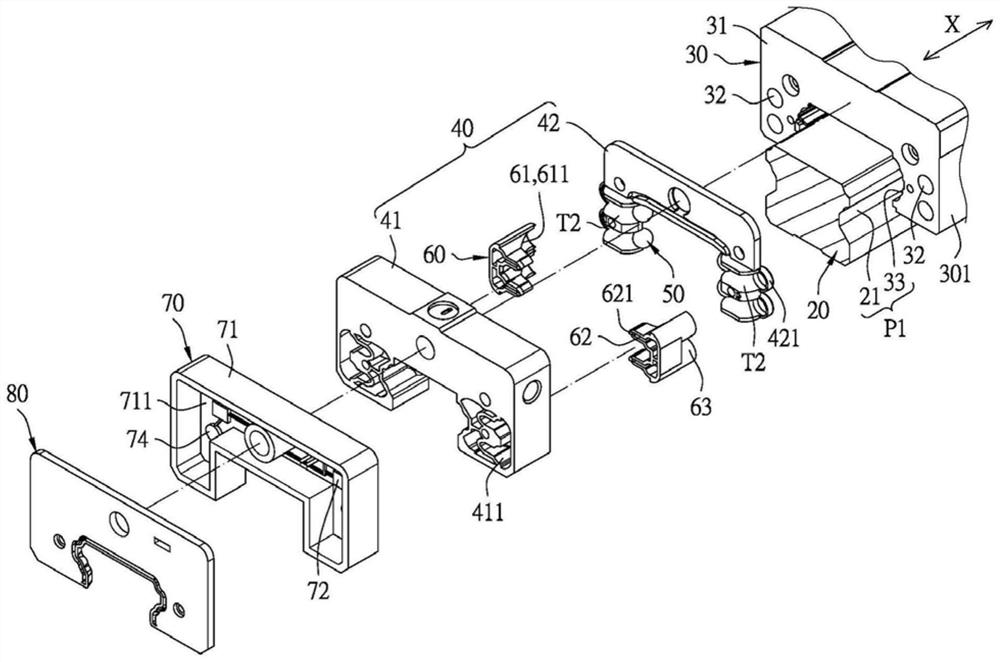

[0067] like Figures 2 to 5B As shown, the first embodiment of the present invention provides a linear transmission device, and the linear transmission device takes a linear slide rail as an example, but it is not limited to this, or Figure 10 The ball screw shown, wherein the linear drive comprises:

[0068] The long shaft member 20 extends along the axial direction X and has a rolling groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com