Fiber body stacking device and fiber structure manufacturing device

一种纤维体、纤维的技术,应用在纤维体堆积装置以及纤维结构体制造装置领域,能够解决混入较多、厚度不均、纤维不均等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

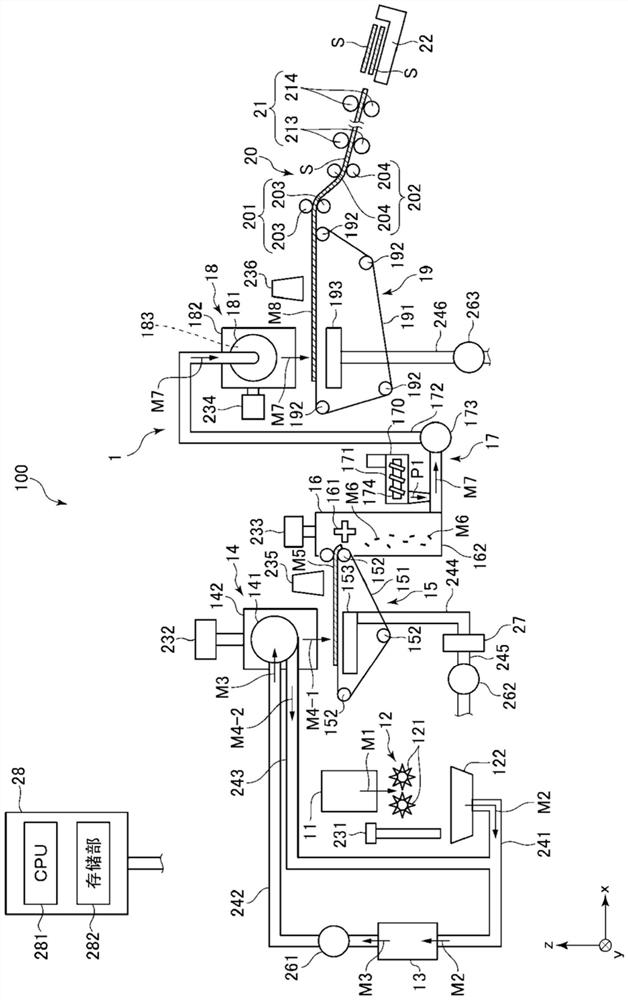

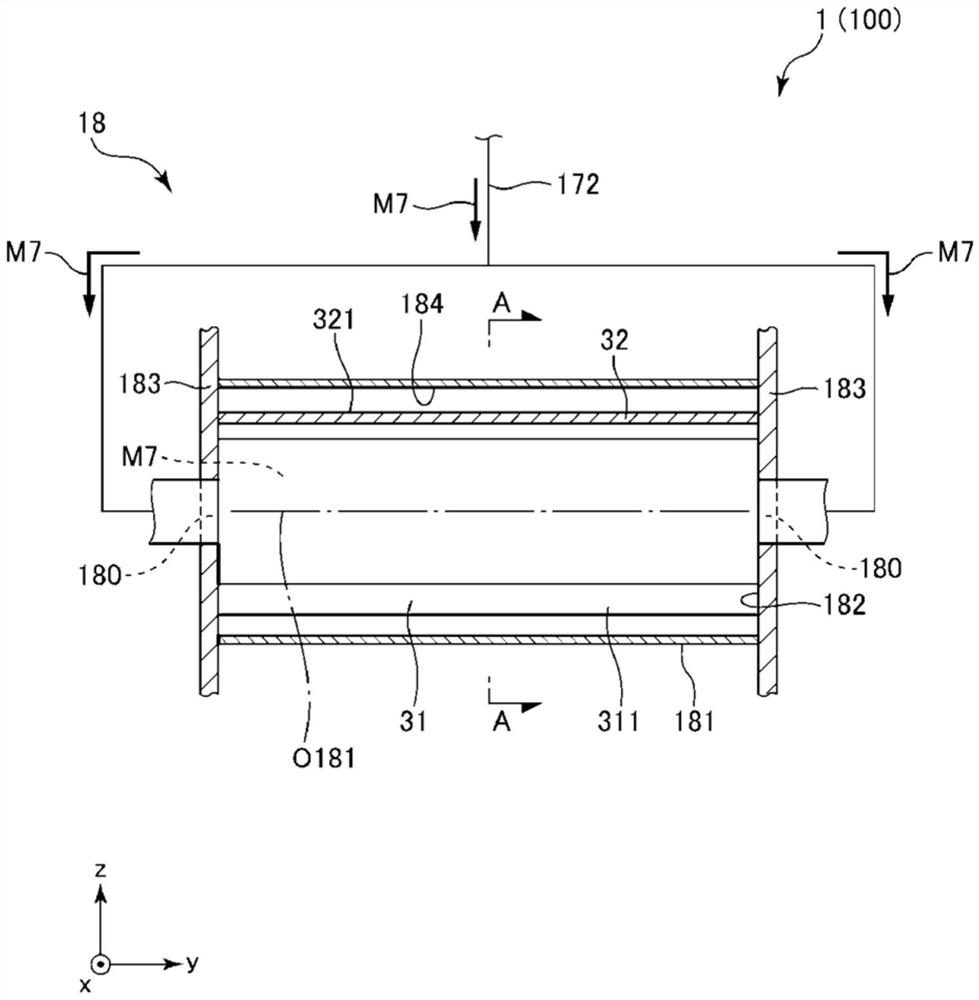

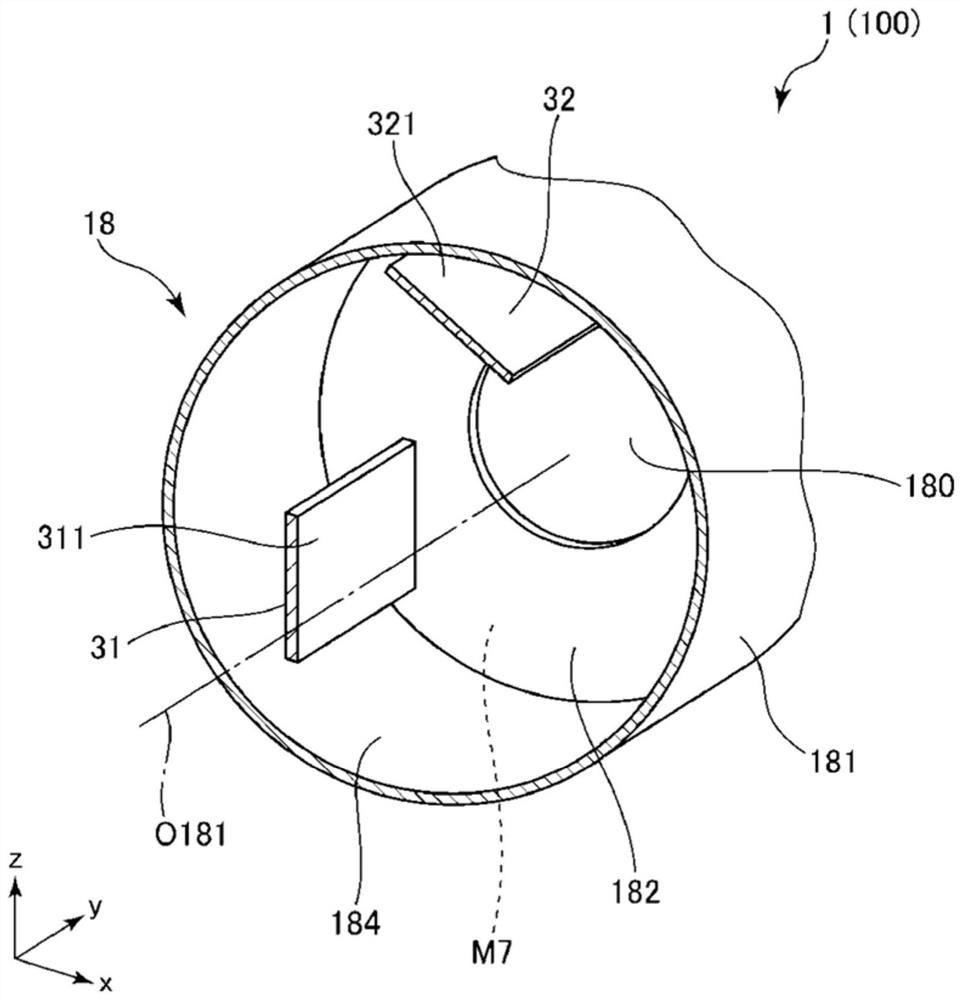

[0016] figure 1 It is a schematic side view showing a fibrous structure manufacturing device including the fibrous body stacking device according to the first embodiment. figure 2 for figure 1 It is a longitudinal cross-sectional view of a drum included in the shown fiber body stacking device. image 3 for figure 2 Perspective view of the drum shown. Figure 4 for figure 2 The A-A line sectional view in. Figure 5 and Image 6 for figure 2 A-A line sectional view in , and is a diagram showing a state in which the material is disassembled.

[0017] In addition, in the following, for the convenience of description, thus as Figure 1 to Figure 6 As shown, let the three mutually orthogonal axes be x-axis, y-axis, and z-axis. Also, the xy plane including the x-axis and the y-axis becomes horizontal, and the z-axis becomes vertical. In addition, the direction to which the arrow mark of each axis points is called "+", and the opposite direction is called "-". Additiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com