Prism structure with non-uniformly distributed bulge structures

A uniform distribution and prism technology, applied in prism, installation, optics and other directions, can solve the problems of large use limitations, increased angles that cannot be refracted, and poor refraction effects, so as to achieve fixed positioning and increase the overall refraction Angle, the effect of improving the overall adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

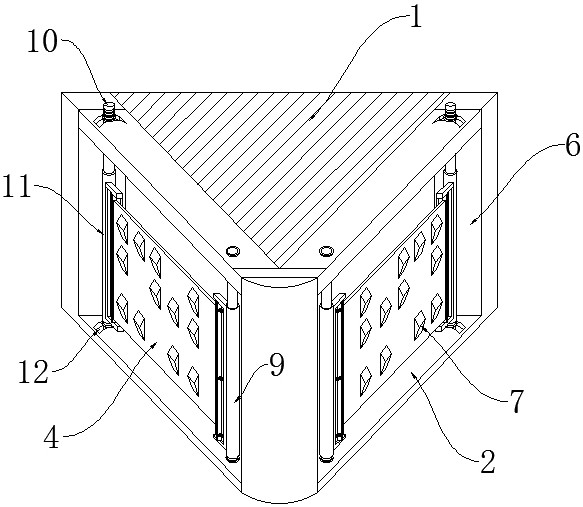

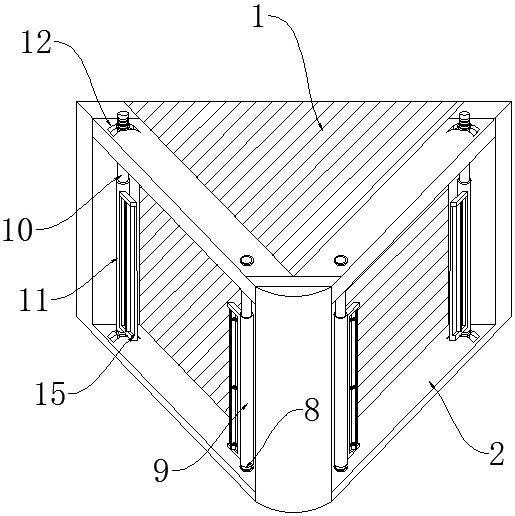

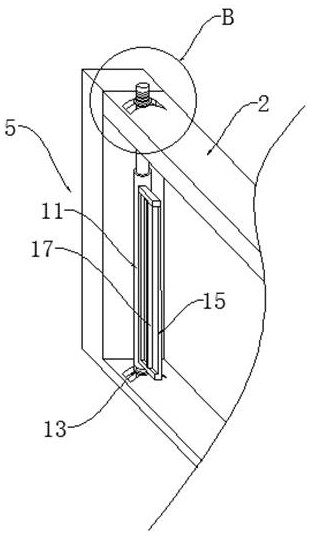

[0023] like Figure 1-6 As shown, the present invention provides a technical solution: a prism structure with unevenly distributed protrusion structures, including a prism body 1, two sets of extension frames 2, two sets of positioning components 3, two sets of raised plates 4 and two sets of adjustment components 5. The extension frames 2 of the two groups are correspondingly pressed on the emission surfaces on both sides of the prism body 1. The extension frame 2 is correspondingly provided with a rectangular installation area 6, and the adjustment components 5 of the two groups are correspondingly installed on both sides of the prism body 1. In the side rectangular installation area 6, the positioning assembly 3 is correspondingly installed on the adjustment assembly 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com