Automatic glue dispensing device of guide rail boxing machine and using method

A technology of automatic glue dispensing and cartoning machine, which is applied to devices and coatings that apply liquid to the surface. Dispensing uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0030] Example one

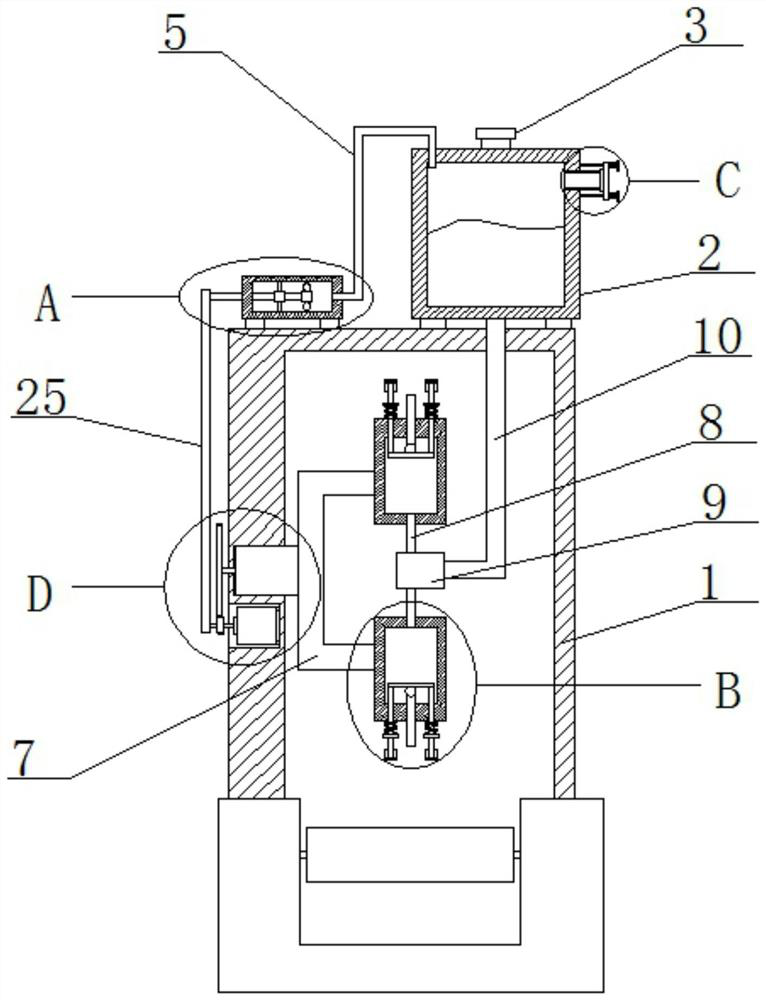

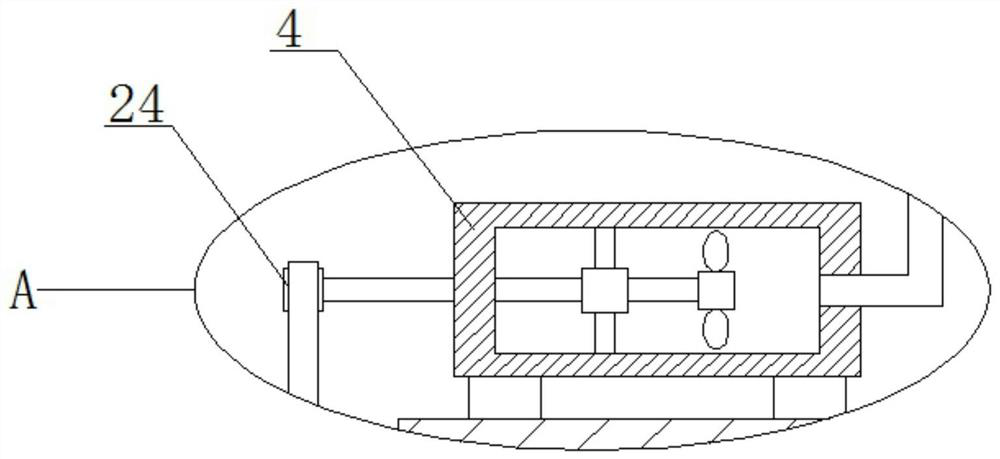

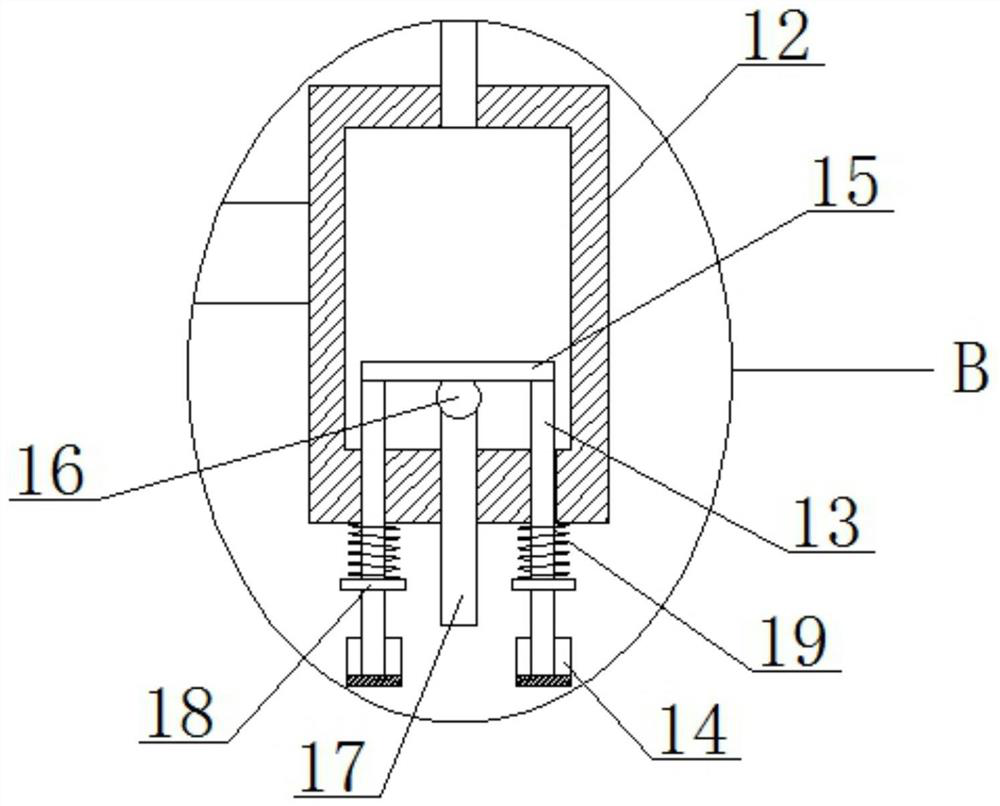

[0031] Refer Figure 1-5 The automatic dispensing device of a guide rail box includes a housing 1, and a reservoir 2 is fixedly coupled to the top of the housing 1, and a top cover 3 is provided with a top cover 3, and a pneumatic pressure is fixed to the top of the housing 1. The pump 4, one side of the air pressure pump 4 is connected to the air pressure pipe 5, and one end of the air pressure pipe 5 is connected to the top of the storage case 2, and the inner wall of the casing 1 is opened, and the rotary groove is rotated, and the rotary groove is rotated and mounted with the rotary shaft 6. One end of the rotating shaft 6 is fixedly connected to the connecting frame 7, and there is a plurality of dispensing mechanisms on the connecting frame 7, and the plurality of dispensing mechanisms are connected to the adhesive tube 8, and the plurality of adhesive tubes 8 are connected to the same connection. The tube 9, the bottom of the storage case 2 is connected ...

Example Embodiment

[0038] Example 2

[0039] Refer Figure 1-5 The automatic dispensing device of a guide rail box includes a housing 1, and the top portion of the housing 1 is secured by welding, and the top cover 3 is provided with a top cover 3, and the top of the housing 1 is passed through the bolt. The air pressure pump 4 is fixedly connected, and the air pressure pipe 5 is connected to the side of the air pressure pump 4, and one end of the air pressure pipe 5 is connected to the top of the storage case 2, and the inner wall of the casing 1 has a rotary groove, rotating in the rotary groove. There is a rotating shaft 6, one end of the rotating shaft 6 is fixedly coupled with a connecting frame 7 by welding, and a plurality of dispensing mechanisms are fixed to the connecting frame 7, and the plurality of dispensing mechanisms are connected to the adhesive tube 8, and the plurality of adhesive tubes 8 are connected. The same connecting tube 9 is connected, and the bottom of the storage case 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com