Inverted quantifiable container

A technology for containers and container mouths, which is applied in the direction of bottle/container caps, caps, caps, etc., which can solve problems such as large quantitative errors, unusable, rolling beads stuck and blocked, etc., to achieve smooth and efficient use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In Embodiment 1, the cover 2 is connected to the mouth 11 of the container through threads, and the cover 2 can also be integrally connected to the container body 1 through a connecting belt to be reversibly fastened to the mouth 11 of the container.

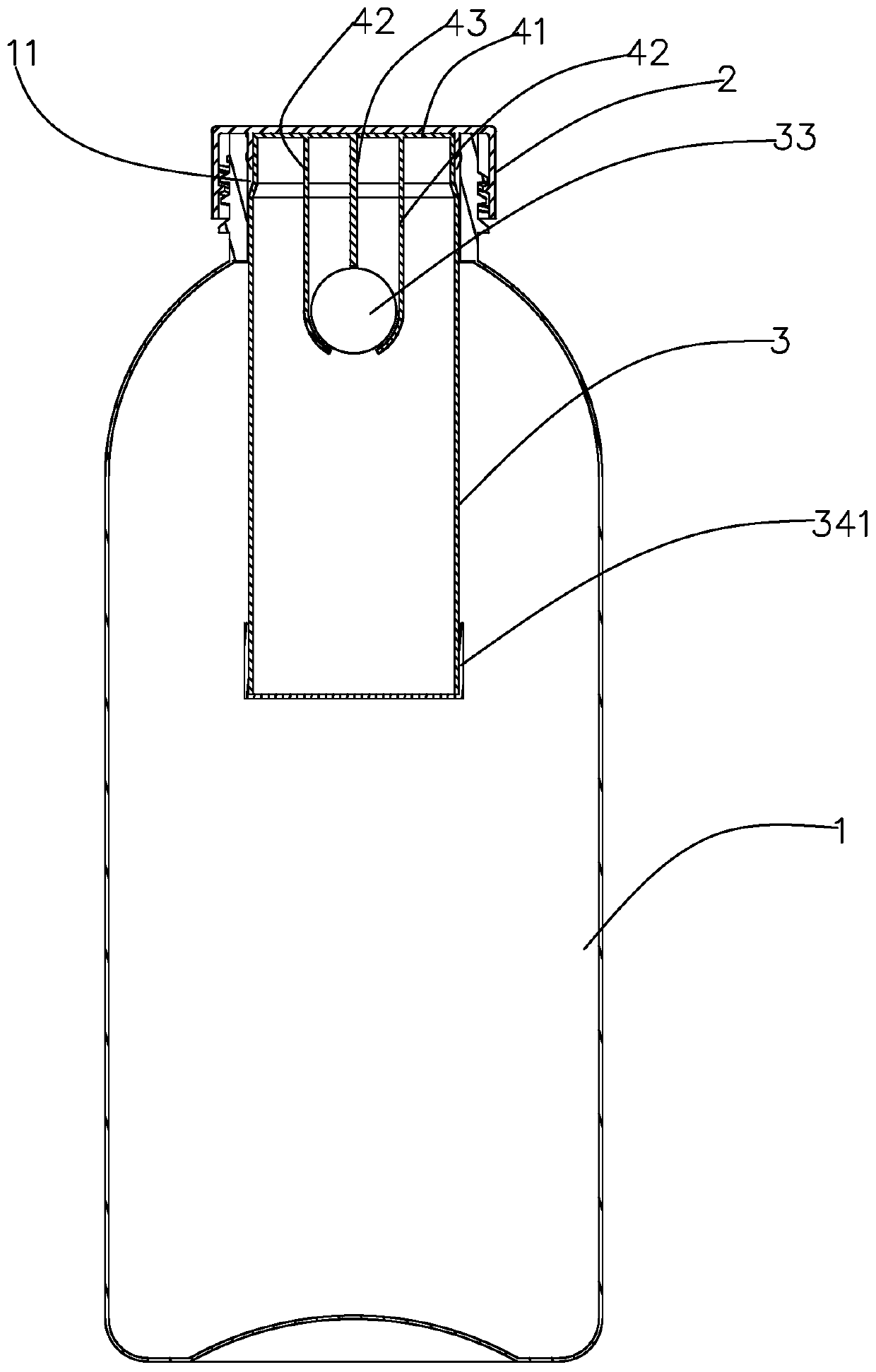

[0037] When using Example 1, the container body is tilted against the liquid outlet side, and the rolling ball is separated from the liquid inlet to open the liquid inlet. At this time, the liquid in the inner cavity of the container body enters the liquid storage cylinder through the liquid inlet hole Inside, when the liquid in the liquid storage cylinder meets the usage amount, stand the container upright, open the cover, and then tilt the container body to the side with the liquid outlet, and the rolling ball will be under the action of gravity and the guide limit structure And the liquid inlet is blocked, and now the inner cavity of the container body and the inner cavity of the liquid storage cylinder are isolated fro...

Embodiment 2

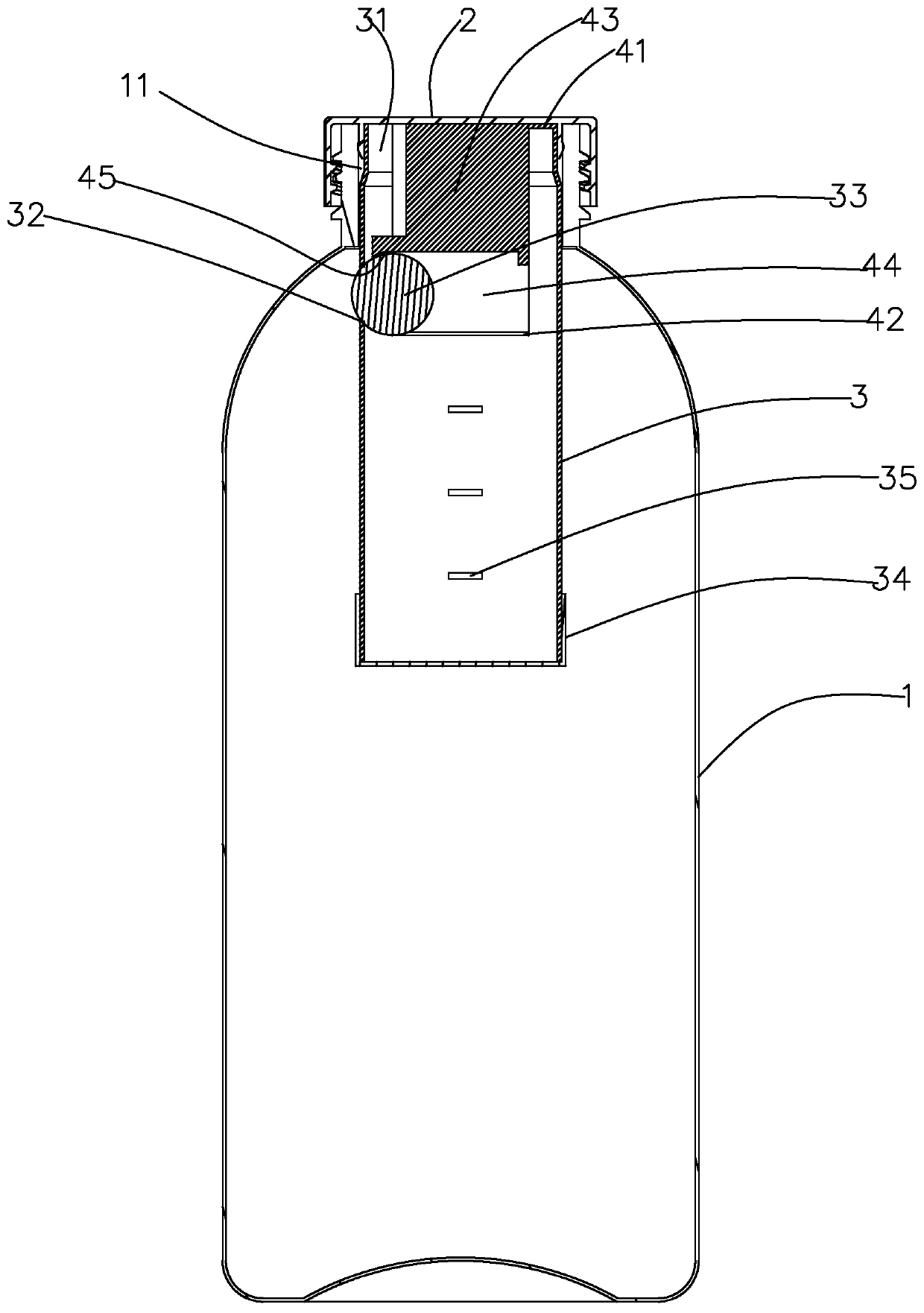

[0040] In Embodiment 2, the cover 2 is screwed to the container mouth 11 , and the cover 2 can also be fastened to the container mouth 11 as required.

[0041] The usage principle of embodiment 2 is the same as that of embodiment 1.

Embodiment 3

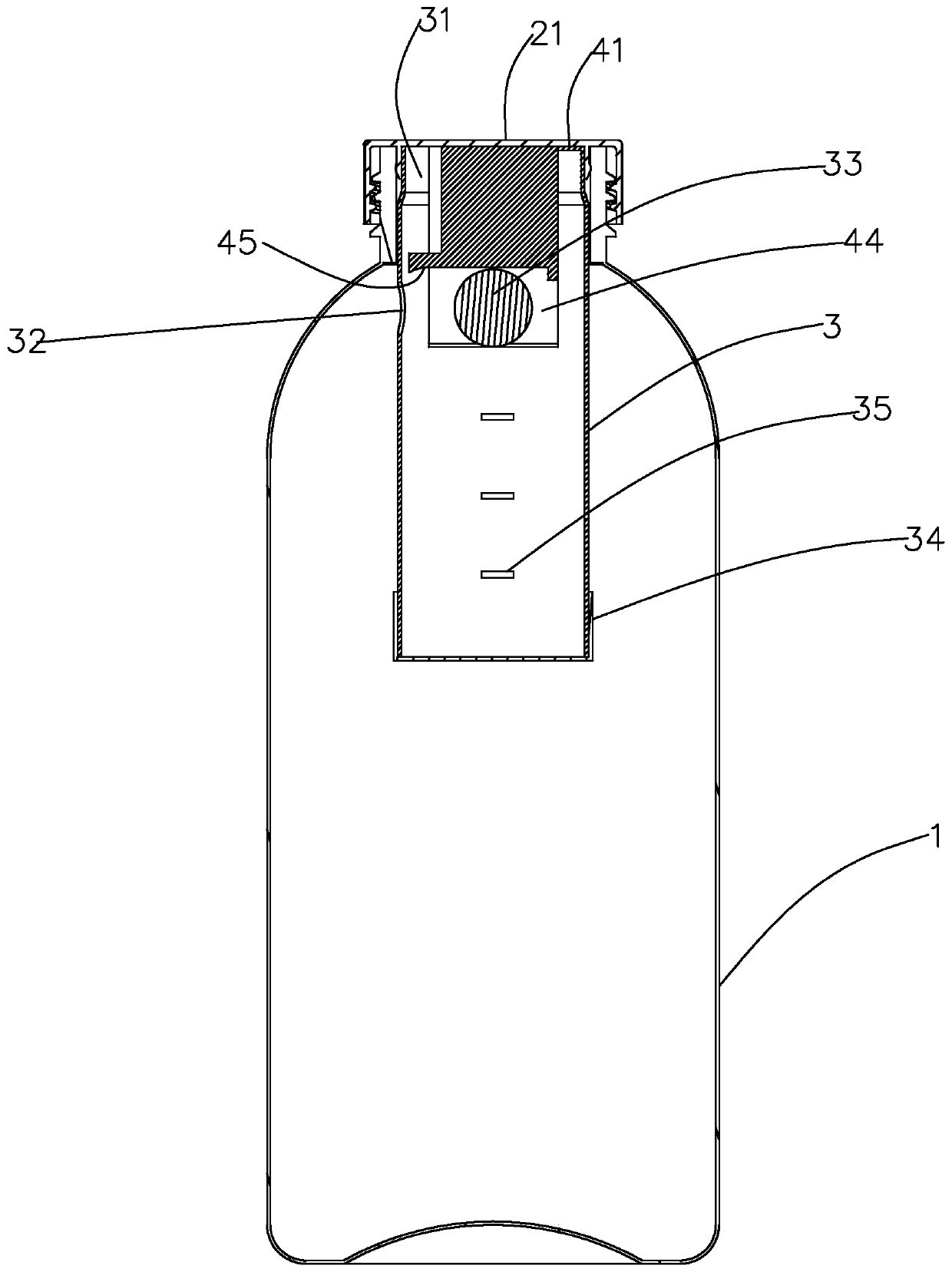

[0043] The working principle of embodiment 3 is the same as that of embodiment 1. In Embodiment 1, the cover 2 is connected to the upper mouth of the connection base 12 through threads; if necessary, the cover 2 can also be integrally connected to the connection base 12 through a connection belt and reversibly fastened to the connection base 12. Base 12 upper mouth.

[0044] Such as Figure 11-12 As shown, as a specific embodiment 4 of the present invention, the difference from embodiment 3 lies in the structure and connection method of the cover and the connection base, that is, the cover 2 is rotatably fastened to the upper mouth of the connection base 12, so The side of the cover 2 is provided with a liquid discharge notch 21, and the side of the upper mouth of the connection base 12 is provided with a fixed liquid discharge notch 121. When the cover 2 is rotated relative to the connection base 12, the liquid discharge notch 21 can be moved. Align with the liquid outlet g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com