Test system for fatigue life of cooling channels

A technology of cooling channels and fatigue life, applied in the field of aerospace universities, can solve the problems of inability to judge the fatigue life of cooling channels, coolant leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

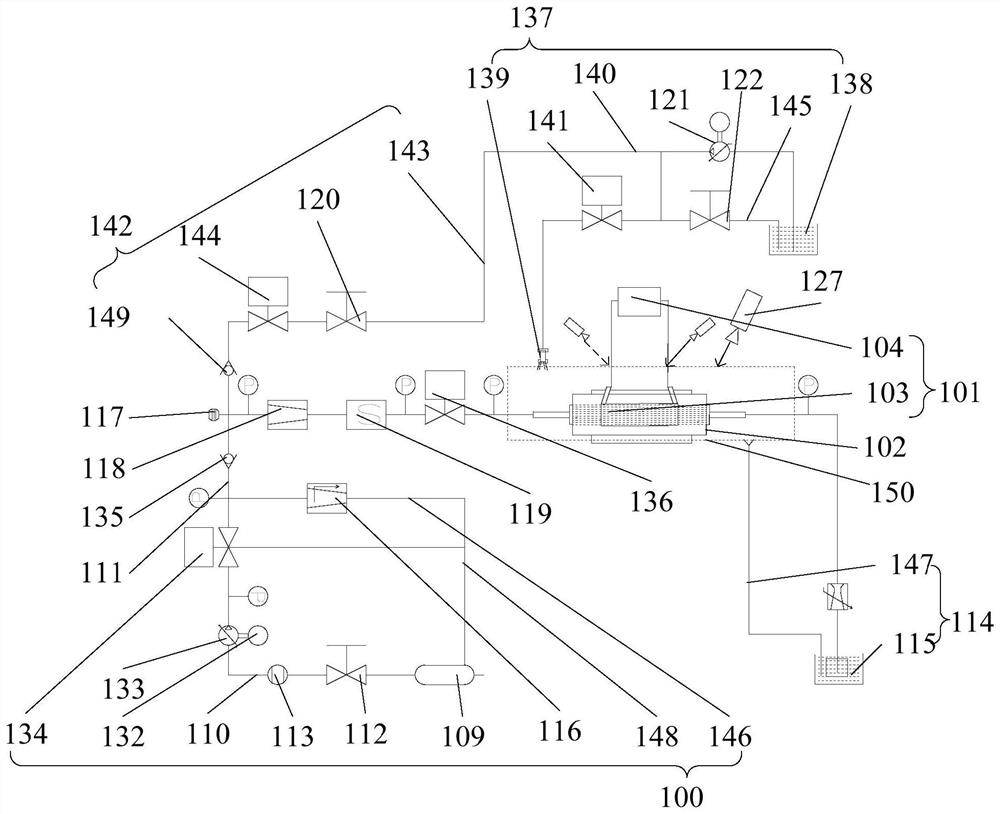

[0058] combine figure 1 As shown, a testing system for fatigue life of cooling channels includes: a coolant supply unit 100 and a heating unit 101; the coolant supply unit 100 is used for supplying coolant to the cooling channel 102; the heating unit 101 heating the cooling channel 102 with a preset heating temperature, a preset heating time and a preset number of times of heating;

[0059] Specifically, first, the heating unit 101 is used to perform a single time on the cooling channel 102 with a preset heating time, wherein the heating efficiency of the heating unit 101 simulates the actual ignition of the liquid rocket engine; then the cooling channel 102 is heated with a preset number of heating times, Heating is stopped until cracks appear in the cooling channel 102 ; finally, the fatigue life of the cooling channel 102 can be calculated according to the preset heating temperature, the preset heating time and the preset heating times of the heating unit 101 .

[0060] In...

Embodiment 2

[0102] The testing system for fatigue life of cooling channels in the second embodiment is an improvement on the basis of the above-mentioned embodiment. The technical content disclosed in the above-mentioned embodiment is not described repeatedly, and the content disclosed in the above-mentioned embodiment also belongs to this embodiment. 2. The contents of the disclosure.

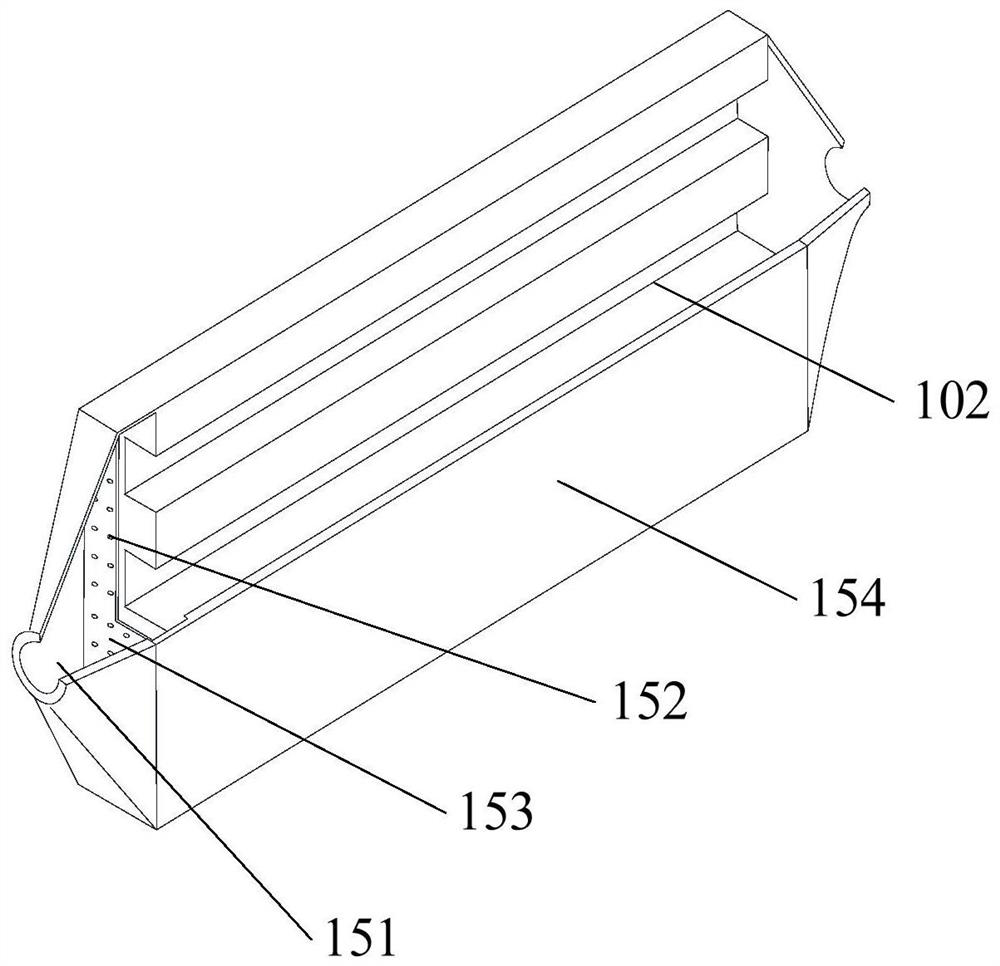

[0103] In this embodiment, the heating unit 101 includes an induction coil 103, a power source 104 and a magnetic component; the induction coil 103 is connected to the power source 104; the induction coil 103 has an accommodating space, and the test panel is arranged in the accommodating space In the space, one end face of the test panel is the test face 154, the test face 154 is the heated face, the end face opposite to the test face 154 is provided with a magnetic element, and the test face 154 is the non-heated face.

Embodiment 3

[0105] The testing system for fatigue life of cooling channels in the third embodiment is an improvement on the basis of the above-mentioned embodiments, the technical contents disclosed in the above-mentioned embodiments are not described repeatedly, and the contents disclosed in the above-mentioned embodiments also belong to this embodiment. Three disclosed contents.

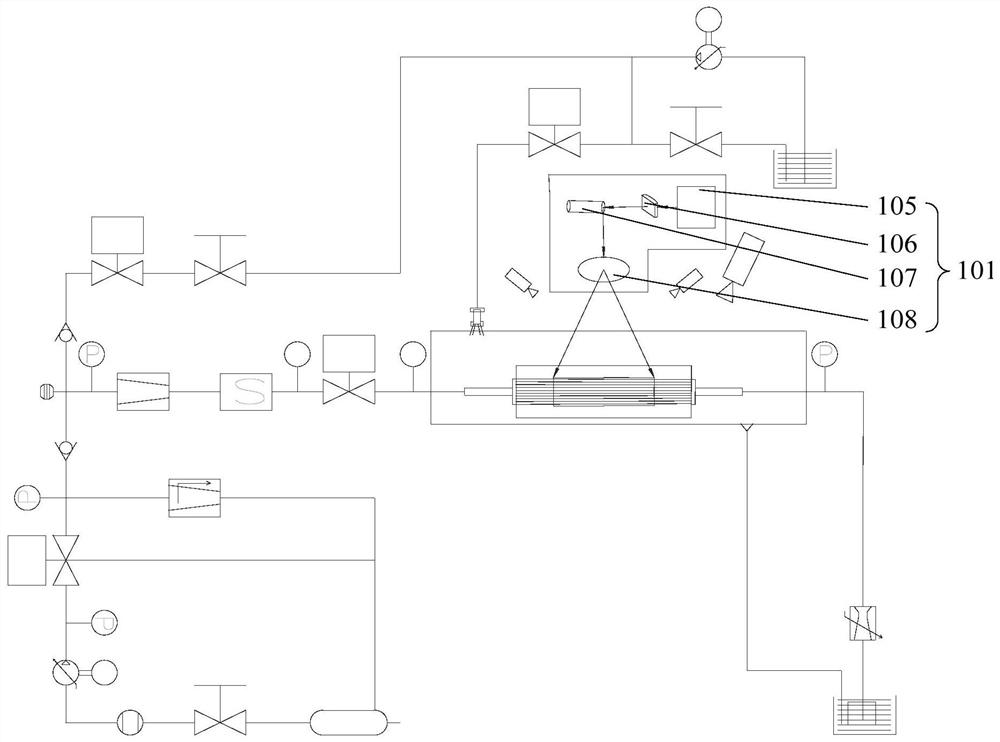

[0106] combine image 3 As shown, in this embodiment, the cooling channel 102 is heated by means of laser heating. Specifically, laser heating is to use laser energy to heat the cooling channel 102, so that the laser beam is radiated on the side of the cooling channel 102 to be heated. , The laser power in the radiation area is high, and the heating speed is fast, the efficiency is high, the beam adjustment is convenient, and it is easier to digitally control and automate operations.

[0107] Specifically, the heating unit 101 includes a laser source 105, a scanning galvanometer 107, a shaping mirror 106 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com