Energy-saving and environmentally-friendly free feeding, transporting and storing structure for particle materials

A technology of granular materials, energy saving and environmental protection, applied in the field of warehousing, it can solve the problems of not being too long in conveying length, difficult to absorb direction, and not being able to be used in medium and long distance transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

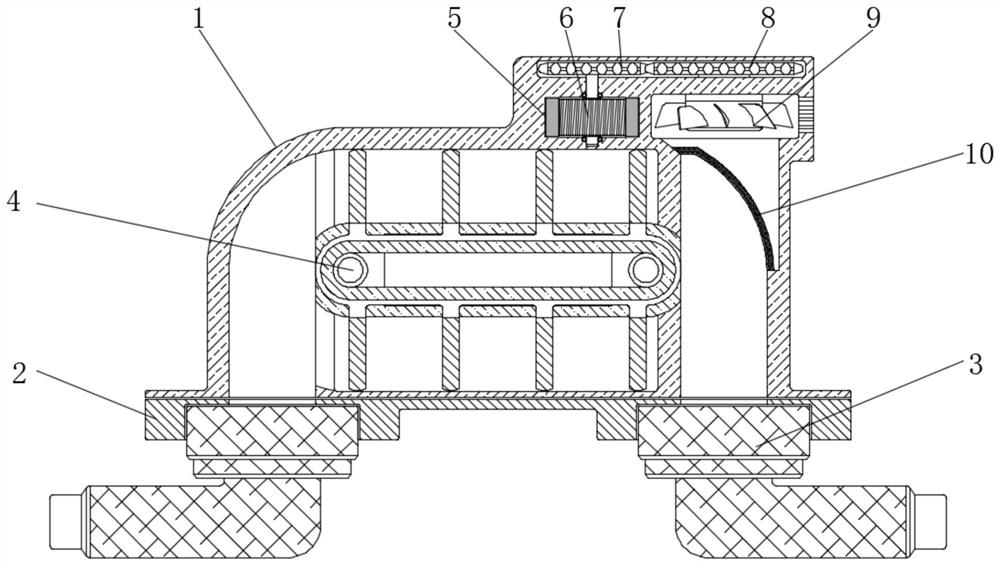

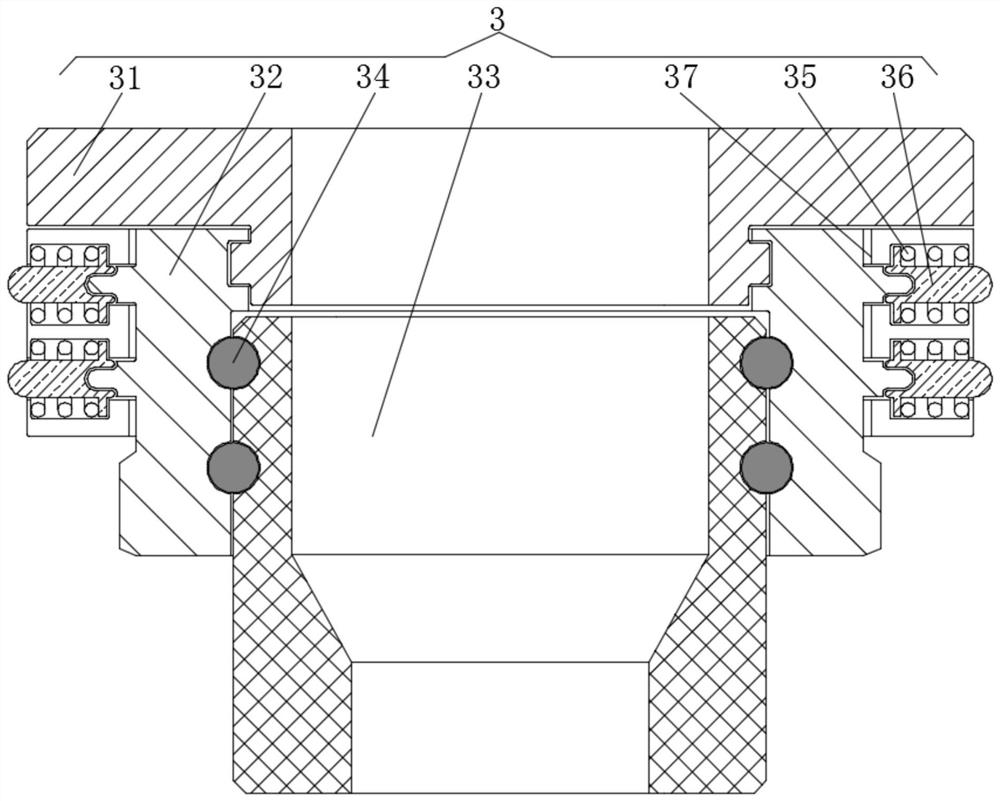

[0024] see figure 1 with image 3 , an energy-saving and environment-friendly granular material free-feed transport storage structure, including a frame 1, the inside of the frame 1 is provided with a rectangular cavity adapted to the conveying mechanism 4, and the inside of the frame 1 is provided with an absorption tube mechanism 3. The frame 1 is equipped with a circular through hole, and the inside of the frame 1 is provided with an output hole that is compatible with the absorption wheel 9. The bottom of the frame 1 is fixedly connected with the clamping plate 2, and the bottom of the clamping plate 2 is clamped with the absorbing tube mechanism 3 , the absorption tube mechanism 3 includes a fixed seat 31, the bottom of the fixed seat 31 is rotatably connected with a snap-in sleeve 32, and the inside of the snap-in sleeve 32 is provided with an annular chute adapted to the fixed seat 31, and the snap-in sleeve 32 The inside is provided with a circular through hole adapte...

Embodiment 2

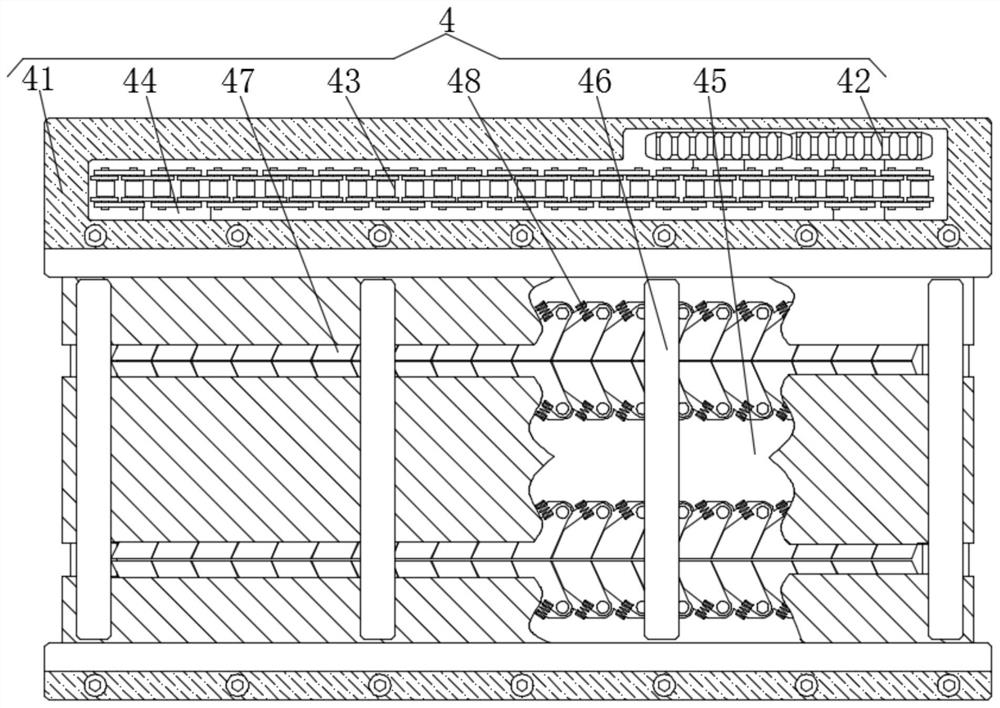

[0026] see Figure 1-2 with Figure 4 , an energy-saving and environment-friendly granular material free-feed transport storage structure, including a frame 1, the inside of the frame 1 is provided with a rectangular cavity adapted to the conveying mechanism 4, and the inside of the frame 1 is provided with an absorption tube mechanism 3. The frame 1 is equipped with a circular through hole, and the inside of the frame 1 is provided with an output hole that is compatible with the absorption wheel 9. The bottom of the frame 1 is fixedly connected with the clamping plate 2, and the bottom of the clamping plate 2 is clamped with the absorbing tube mechanism 3 , the inside of the frame 1 is fixedly connected with a conveying mechanism 4, the conveying mechanism 4 includes a conveying frame 41, the internal rotation of the conveying frame 41 is connected with a conveying wheel 42, the internal rotation of the conveying frame 41 is connected with a conveying shaft 44, and the top of...

Embodiment 3

[0028] see Figure 1-4, an energy-saving and environment-friendly granular material free-feed transport storage structure, including a frame 1, the inside of the frame 1 is provided with a rectangular cavity adapted to the conveying mechanism 4, and the inside of the frame 1 is provided with an absorption tube mechanism 3. The frame 1 is equipped with a circular through hole, and the inside of the frame 1 is provided with an output hole that is compatible with the absorption wheel 9. The bottom of the frame 1 is fixedly connected with the clamping plate 2, and the bottom of the clamping plate 2 is clamped with the absorbing tube mechanism 3 , the absorption tube mechanism 3 includes a fixed seat 31, the bottom of the fixed seat 31 is rotatably connected with a snap-in sleeve 32, and the inside of the snap-in sleeve 32 is provided with an annular chute adapted to the fixed seat 31, and the snap-in sleeve 32 The inside is provided with a circular through hole adapted to the suct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com