Vertical rolling mill base foundation bolt pre-embedding device

A technology of anchor bolts and pre-embedded devices, which is applied in the direction of metal rolling mill stands, metal rolling racks, metal rolling, etc., can solve problems such as inability to meet production needs, inaccurate bolt pre-embedding, sagging, etc., and achieve rapid The effect of efficient positioning and embedding operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

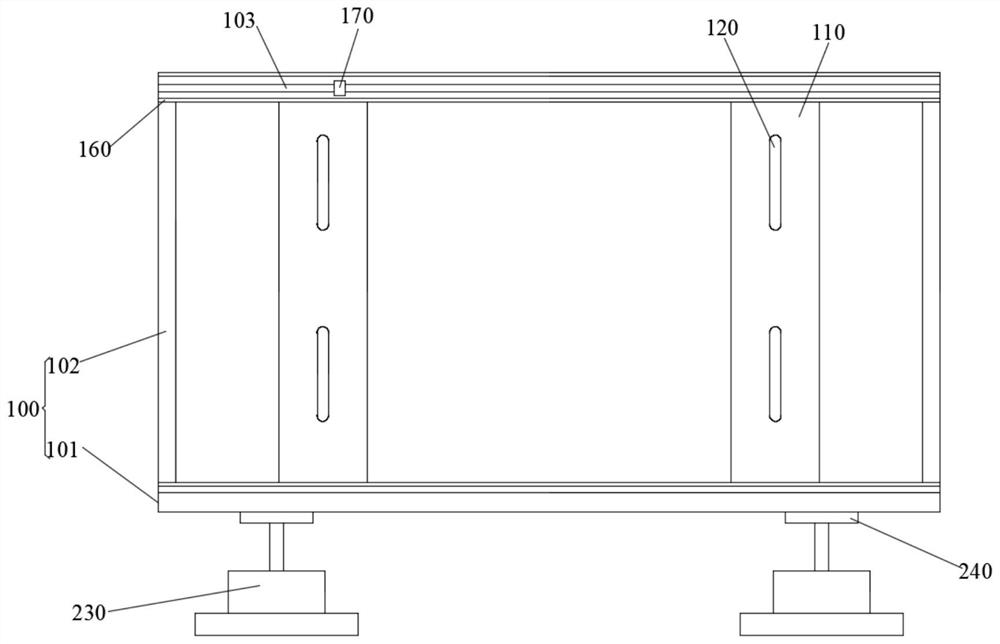

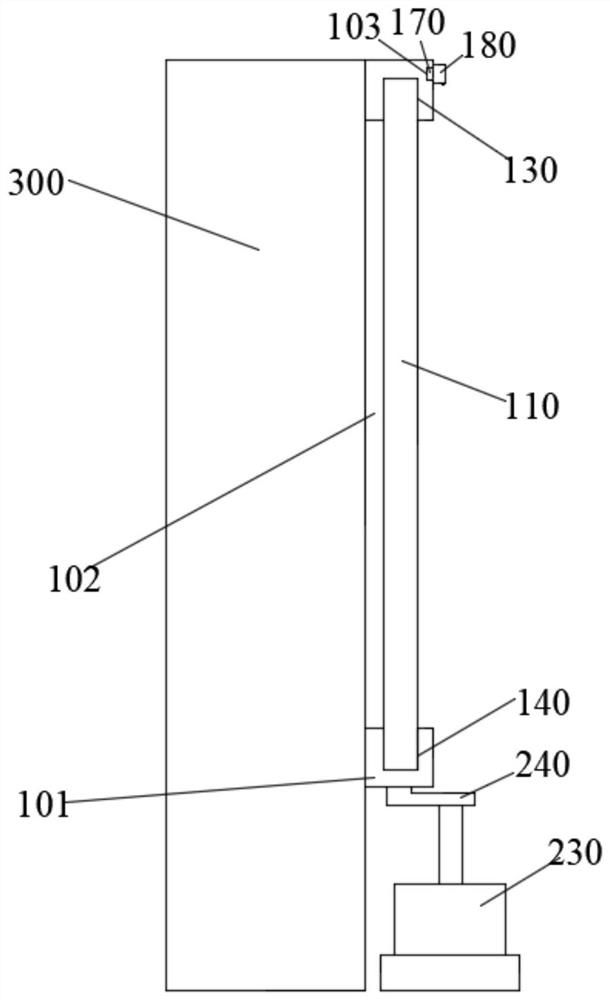

[0035] Such as figure 1 and figure 2 As shown, the embodiment of the present application provides a pre-embedded device for foundation bolts of a vertical rolling mill base, which includes a vertically arranged positioning frame 100, two positioning plates 110 and a lifting device for driving the positioning frame 100 up and down. The positioning plates 110 are arranged in sequence along the length direction of the positioning frame 100 and are configured to be movable along the length direction of the positioning frame 100. Each positioning plate 110 is provided with two bolt positioning bar holes arranged at intervals up and down and running through its two sides. 120. Wherein, the positioning frame 100 is composed of two vertical plates 101 arranged up and down and two horizontal plates 102 arranged left and right. The bottom is bent upwards to form a chute 140, the top and bottom of the two positioning plates 110 are respectively slid in the upper chute 130 and the chut...

Embodiment 2

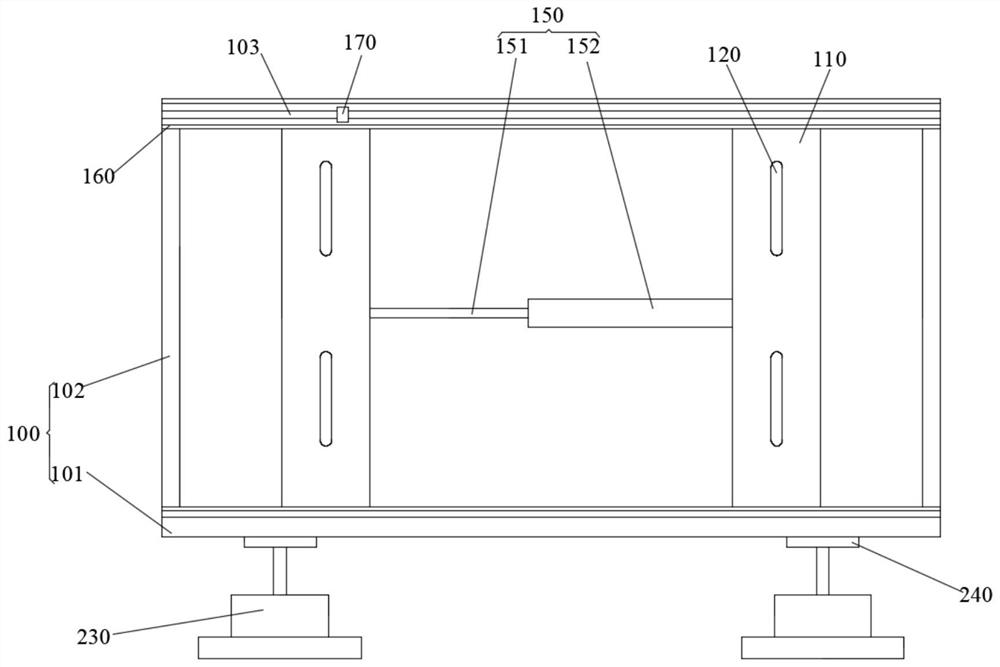

[0039] Such as image 3 As shown, the embodiment of the present application provides a vertical rolling mill base anchor bolt pre-embedded device, which has roughly the same structure as the vertical rolling mill base anchor bolt pre-embedded device provided in Example 1. The difference is that in this embodiment The pre-embedded device for the foundation bolts of the vertical rolling mill base also includes a first telescopic rod 150. The first telescopic rod 150 includes a first threaded rod 151 and a first threaded cylinder 152 threaded on one end of the first threaded rod 151. Both ends of a telescoping rod 150 are detachably connected to the two positioning plates 110 via connecting bolts.

[0040] The pre-embedded device for anchor bolts at the base of the vertical rolling mill provided in this embodiment can quickly and efficiently locate and fix multiple groups of bolts at fixed intervals along the horizontal direction. The operator first rotates the first threaded rod...

Embodiment 3

[0042] Such as Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, the embodiment of the present application provides a vertical rolling mill base anchor bolt pre-embedded device, which has roughly the same structure as the vertical rolling mill base anchor bolt pre-embedded device provided in Example 2, the difference is that in this embodiment Each positioning plate 110 is connected with two vertical adjustment plates 190 that can move along the bolt positioning bar hole 120, and the vertical adjustment plate 190 is provided with a bolt positioning hole 200, and the bolt positioning hole 200 is used to pass through it. The bolts pass through the corresponding bolt positioning strip holes 120, and each vertical adjustment plate 190 is respectively protruded with a bump 191 that slides and engages with the bolt positioning strip holes 120, and the bolt positioning holes 200 pass through the corresponding bumps 191; Each vertical adjustment plate 190 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com