Mine safety production management information system based on Internet of Things

A technology of safety production management and information system, applied in the field of mine safety production management information system of the Internet of Things, can solve problems such as the inability of mining personnel to provide rescue information to guide directions, and the inability of equipment to improve guarantees, so as to strengthen reinforcement, improve efficiency, and improve escape. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Figure 1 to Figure 6 Shown:

[0029] The invention provides a mine safety production management information system of the Internet of Things,

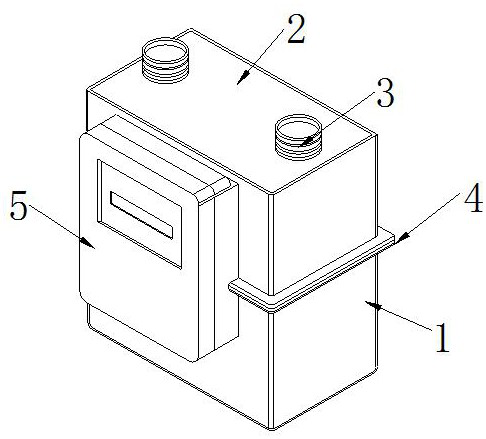

[0030] Its structure includes a system body 1, a cover 2, a positioning end 3, a fixed ring 4, and a monitor 5. The upper end of the system body 1 and the cover 2 are in clearance fit, and the positioning end 3 is fixed on the upper end of the cover 2. The fixing ring 4 is embedded on the outside of the system body 1 , and the monitor 5 is embedded in the fixing ring 4 .

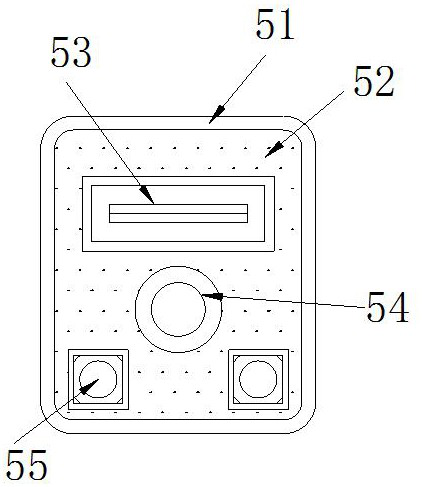

[0031] The monitor 5 is provided with a casing 51, a cavity 52, an input terminal 53, a monitoring hole 54, and a safeguard device 55. The casing 51 is integrated with the cavity 52, and the input terminal 53 is embedded in the cavity 52. The monitoring hole 54 is installed below the input end 53, and the safeguarding device 55 is positioned on both sides below the monitoring hole 54. There are two safeguarding devices 55 below the monitoring hole 54 and fo...

Embodiment 2

[0039] Figure 7 to Figure 9 Shown:

[0040] The invention provides a mine safety production management information system of the Internet of Things,

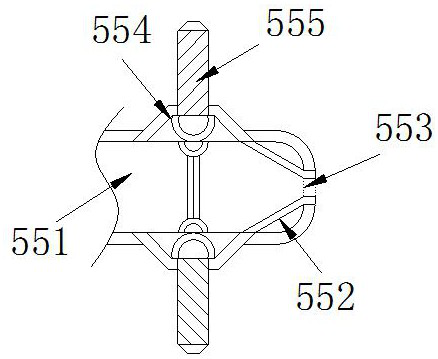

[0041] Its structure includes that the gas channel 551 is provided with a connecting body c1, a spacer block c2, and a unidirectional layer c3, the connecting body c1 is fixedly connected with the spacer block c2, and the unidirectional layer c3 is embedded in the spacer block c2, The front end of the unidirectional layer c3 has an expansion phenomenon, and the unidirectional layer c3 can effectively continuously introduce external air through its own expansion phenomenon and prevent the internal gas from colliding with the external air.

[0042] Wherein, the connecting body c1 is provided with a fitting end c11, a solid layer c12, a sliding rail c13, and a movable body c14, the fitting end c11 is integrated with the solid layer c12, and the sliding rail c13 is installed on the On the side, the movable body c14 is embedded in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com