Safety protection device for disk reading equipment

A technology of safety protection device and reading equipment, which is applied in the protection measures of magnetic heads, the layout of structural components in carrier equipment, and the reduction of physical parameters of carriers, etc., and can solve problems such as data damage and heat accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

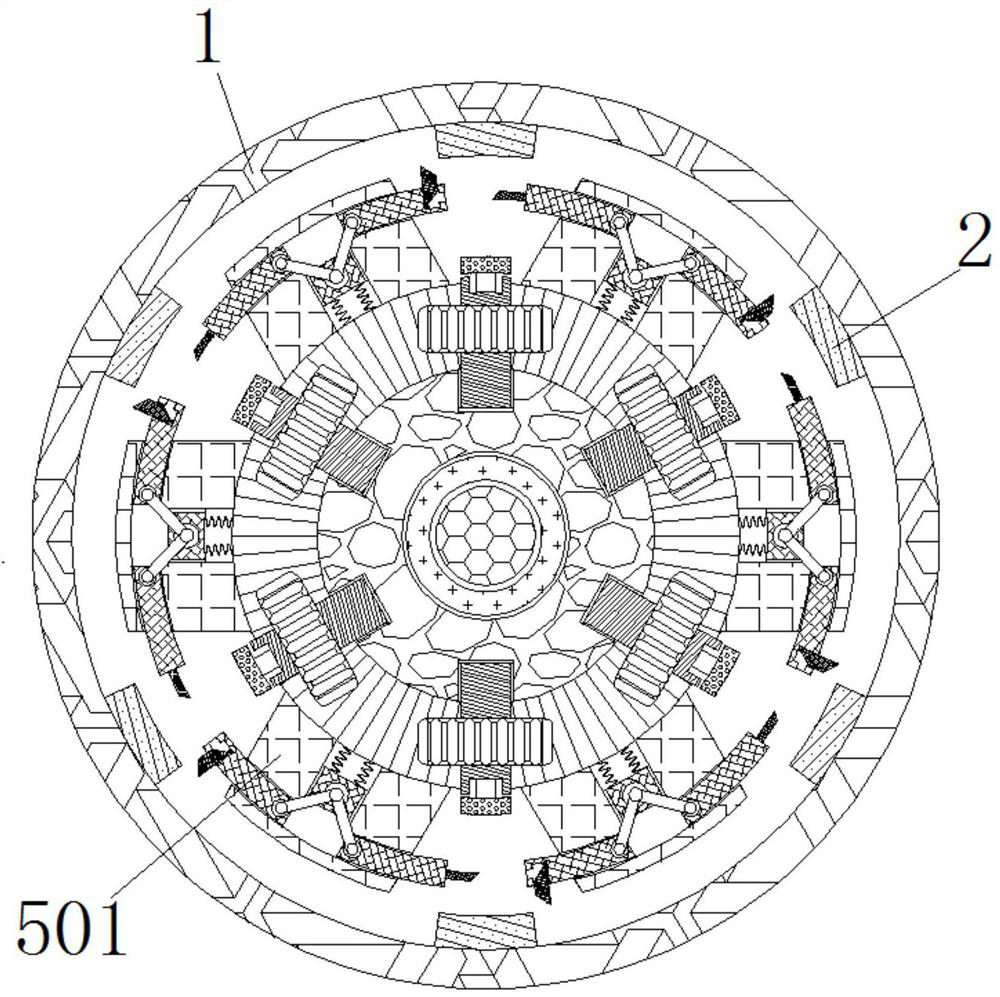

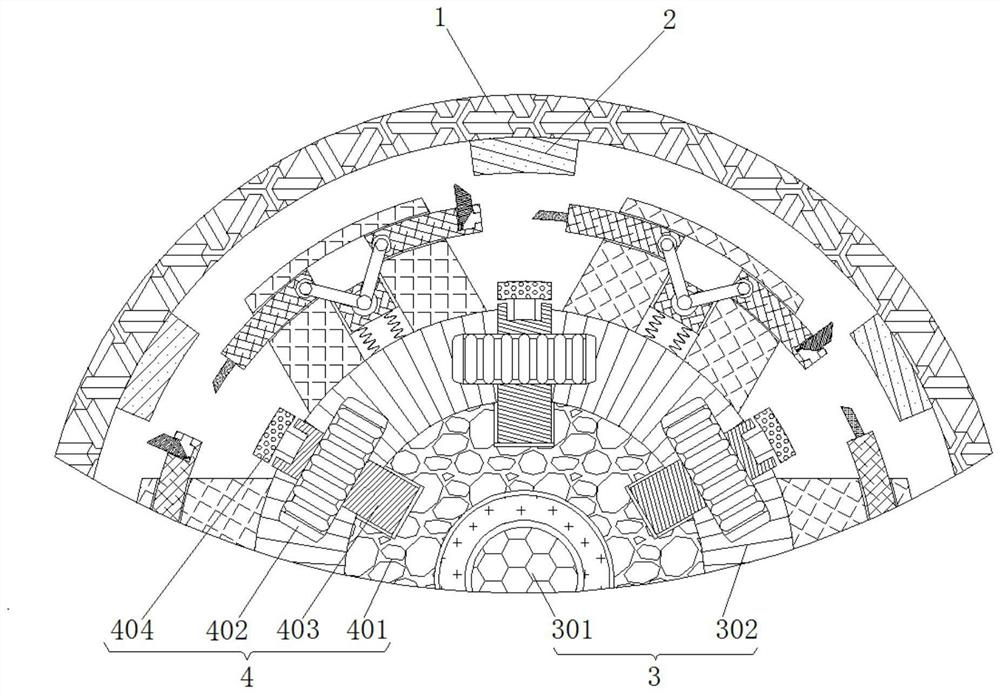

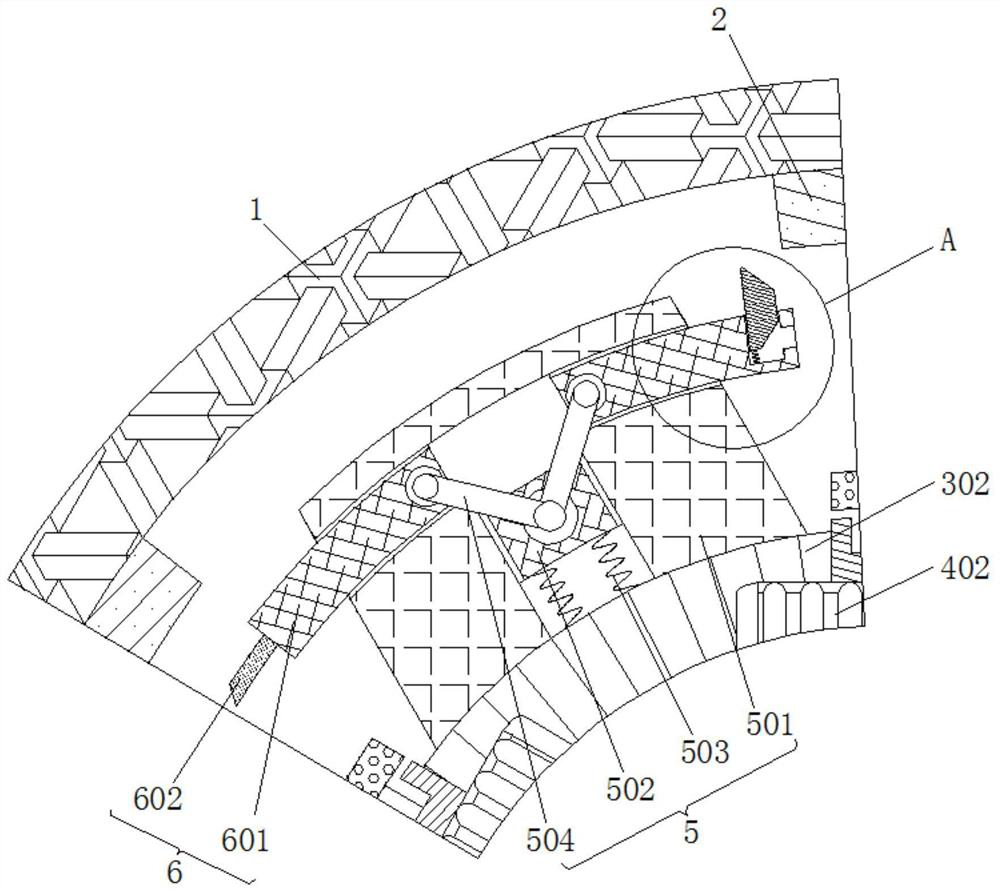

[0026] see Figure 1-2 , a safety protection device for disk reading equipment, including a base 1, the inner side of the base 1 is welded with a limit block 2, and the middle position inside the base 1 is rotatably connected to a power mechanism 3, and the power mechanism 3 includes a rotating shaft 301, which rotates The shaft 301 is rotatably connected to the center of the base 1. The outer side of the rotating shaft 301 and the front of the base 1 are welded with a turntable 302. The outer side of the power mechanism 3 is sleeved with a transmission mechanism 4. The transmission mechanism 4 includes a fixed disk 401, and the fixed disk 401 Socketed on the outside of the rotating shaft 301, the front of the fixed disc 401 is welded to the receiving plate 8, the outer side of the fixed disc 401 is rotatably connected to the transmission shaft 403, the outer side of the transmission shaft 403 is sleeved with a rotating gear 402, and the transmission shaft 403 is away from the ...

Embodiment 2

[0029] see Figure 1-5 , a safety protection device for disk reading equipment, including a base 1, the inner side of the base 1 is welded with a limit block 2, and the middle position inside the base 1 is rotatably connected to a power mechanism 3, and the power mechanism 3 includes a rotating shaft 301, which rotates The shaft 301 is rotatably connected to the center of the base 1. The outer side of the rotating shaft 301 and the front of the base 1 are welded with a turntable 302. The outer side of the power mechanism 3 is sleeved with a transmission mechanism 4. The transmission mechanism 4 includes a fixed disk 401, and the fixed disk 401 Socketed on the outside of the rotating shaft 301, the front of the fixed disc 401 is welded to the receiving plate 8, the outer side of the fixed disc 401 is rotatably connected to the transmission shaft 403, the outer side of the transmission shaft 403 is sleeved with a rotating gear 402, and the transmission shaft 403 is away from the ...

Embodiment 3

[0032] see Figure 1-5 , a safety protection device for disk reading equipment, including a base 1, the inner side of the base 1 is welded with a limit block 2, and the middle position inside the base 1 is rotatably connected to a power mechanism 3, and the power mechanism 3 includes a rotating shaft 301, which rotates The shaft 301 is rotatably connected to the center of the base 1. The outer side of the rotating shaft 301 and the front of the base 1 are welded with a turntable 302. The outer side of the power mechanism 3 is sleeved with a transmission mechanism 4. The transmission mechanism 4 includes a fixed disk 401, and the fixed disk 401 Socketed on the outside of the rotating shaft 301, the front of the fixed disc 401 is welded to the receiving plate 8, the outer side of the fixed disc 401 is rotatably connected to the transmission shaft 403, the outer side of the transmission shaft 403 is sleeved with a rotating gear 402, and the transmission shaft 403 is away from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com