Preparation device and preparation method of crushed stone core composite sample for large triaxial test

A composite sample and triaxial test technology, which is applied in the field of civil engineering, can solve the problems of low efficiency, time-consuming and labor-intensive pre-consolidation, and difficult production, and achieve the effects of convenient operation, shortened pre-consolidation time, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

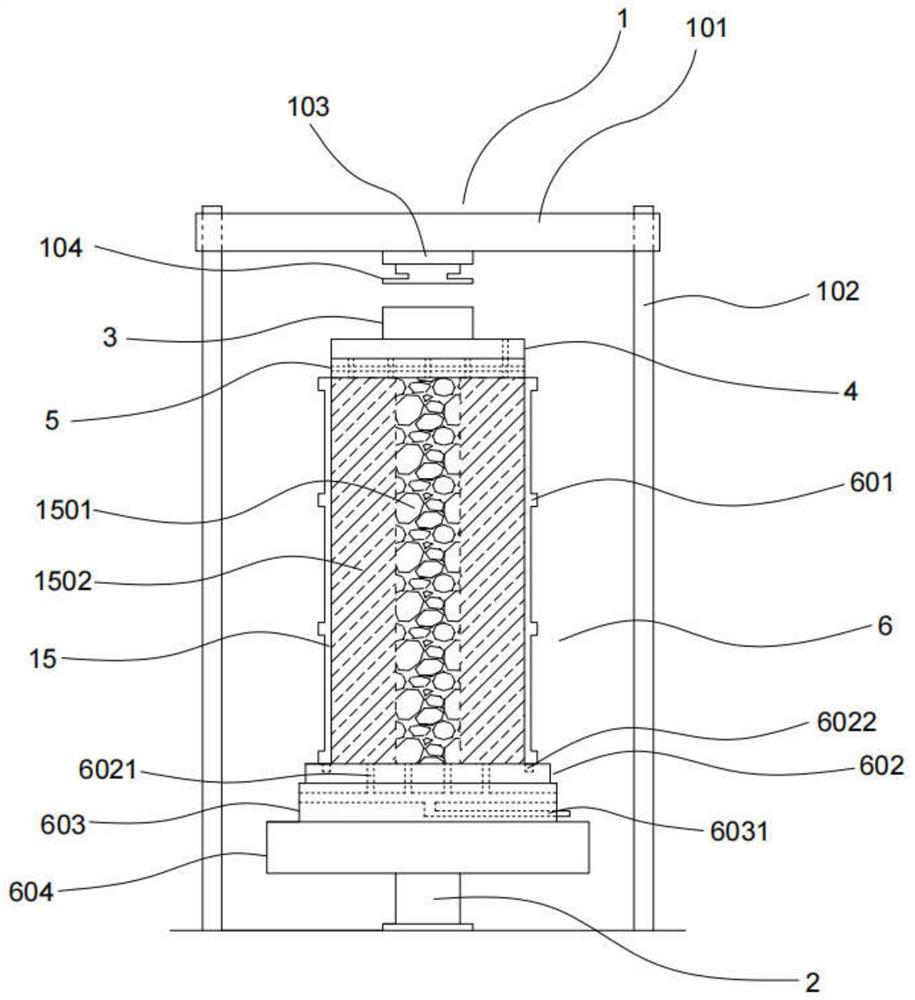

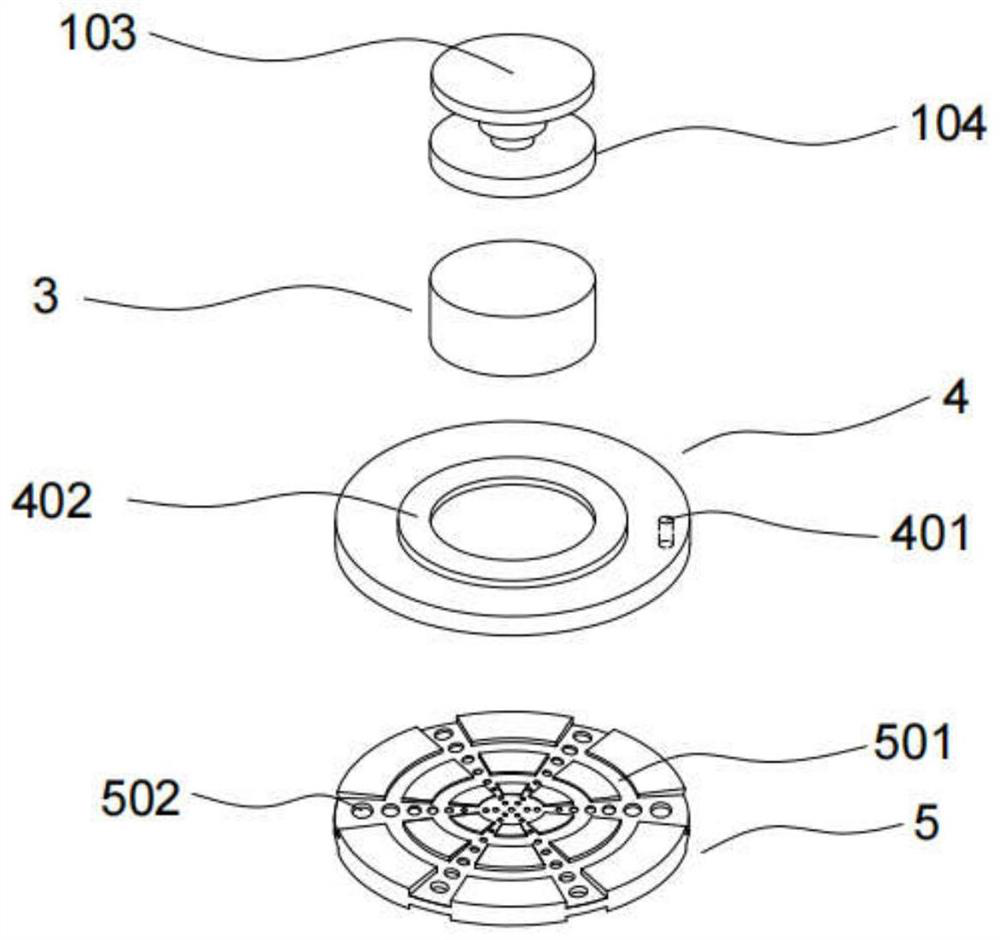

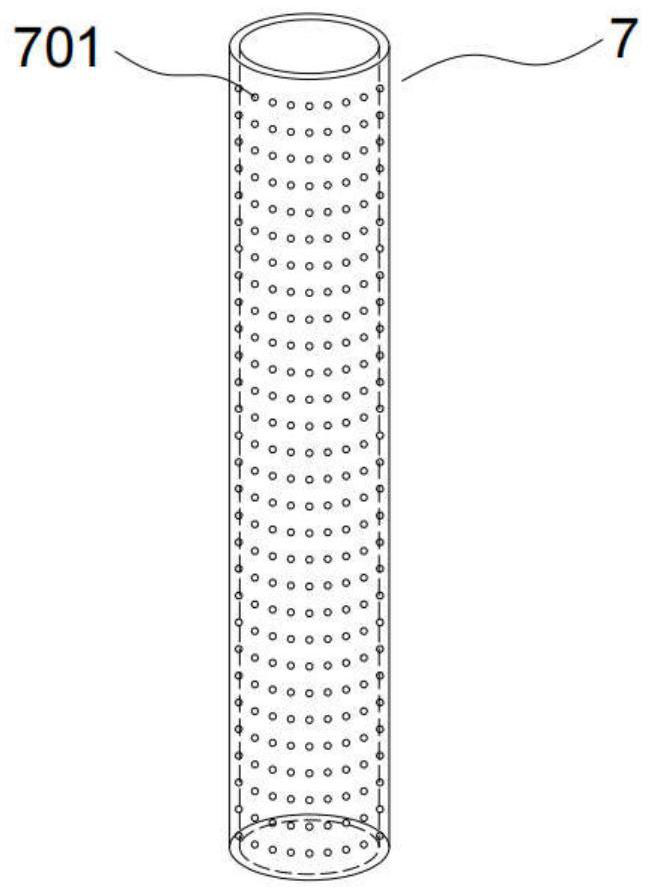

[0043] like figure 1As shown in the figure, a preparation device for a gravel core composite sample for a large triaxial test includes an axial loading frame 1, a pressure transmission mechanism, a sample-bearing mechanism 6 and a lifting rod 2; the sample-bearing mechanism 6 includes a soft clay The forming cylinder 601 of 1502, the porous steel inner tube 7 for loading the crushed stone core 1501, and the supporting base, the porous steel inner tube 7 is arranged inside the forming cylinder 601, the supporting base is set below the forming cylinder 601, and the pressure transmission mechanism is located in the forming cylinder Above 601, the support base and the pressure transmission mechanism are respectively provided with a lower drainage channel and an upper drainage channel that communicate with the forming cylinder 601; the lifting rod 2 is connected under the support base, and the axial loading frame 1 includes a set above the pressure transmission mechanism. The press...

Embodiment 2

[0050] A method for preparing a composite sample of crushed stone cores for a large triaxial test by using the device, comprising the following steps:

[0051] 1. Device construction

[0052] 1.1. Tie the latex film 1504 on the sample base 602.

[0053] 1.2. Install the forming cylinder 601, combine the first forming half cylinder 6011 and the second forming half cylinder 6012 and place them on the sample base 602, ensure that the second screw hole 6022 is aligned with the third screw hole 6014, and use a second bolt Fix the forming cylinder 601 and the sample base 602, and then use the first bolts 6015 to fasten the first forming half cylinder 6011 and the second forming half cylinder 6012.

[0054] 1.3. Pull up the latex film 1504 vertically and turn it over on the outer wall 6017 of the forming cylinder, and make it closely adhere to the inner wall 6016 of the forming cylinder.

[0055] 1.4. Place a circular lower layer filter paper 1503 with a diameter of 300 mm on the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com