Tower crane climbing frame

A climbing frame and tower crane technology, applied to cranes and other directions, can solve the problems of potential safety hazards and inconvenient disassembly of introduced rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

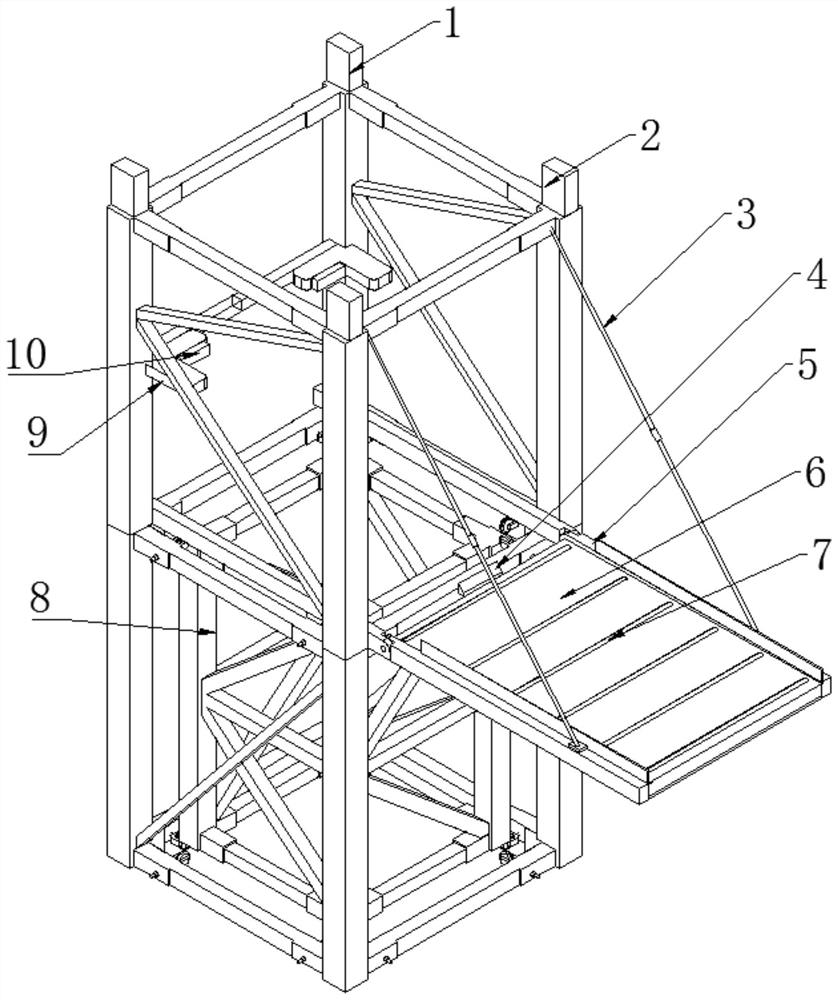

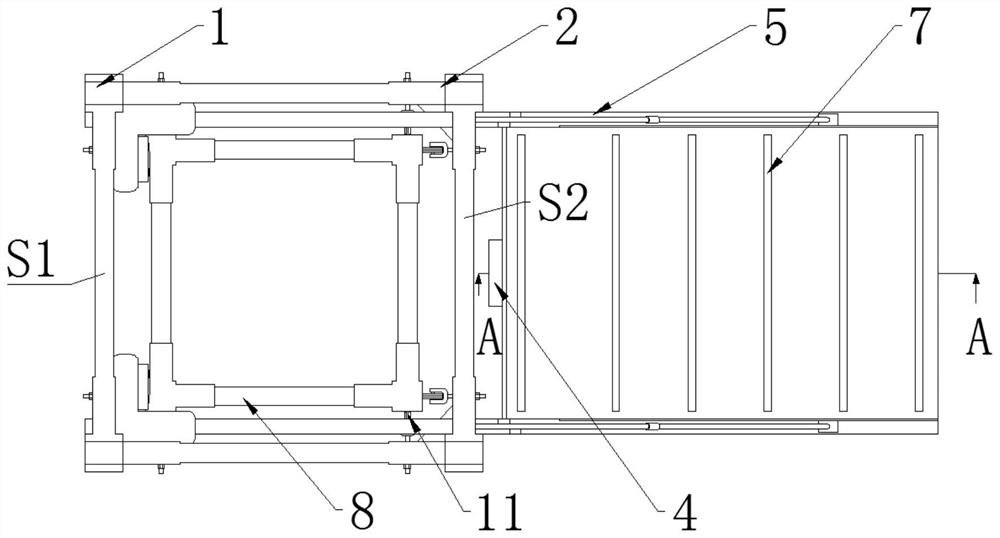

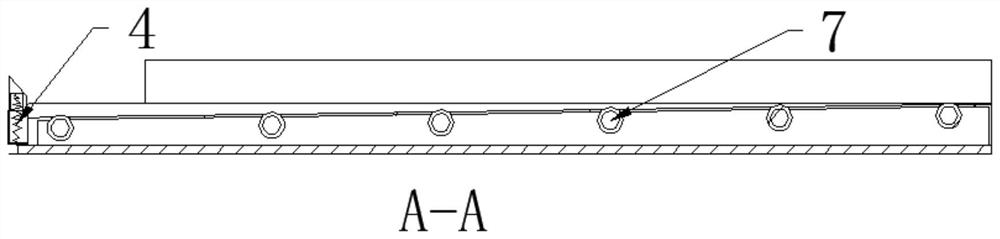

[0023] Example 1 is attached Figure 1~3 As shown, the climbing frame includes an introduction surface S2, a climbing surface S1 opposite to the introduction surface S2, and two connecting surfaces connected between the introduction surface S2 and the climbing surface S1, wherein the introduction surface S2, the climbing surface S1 and the two connecting surfaces The surfaces are connected together by the main chords of the climbing frame to form a frame structure with a quadrilateral cross section. The main chords include two first main chords 2 arranged on the side of the introduction surface S2 and two first main chords 2 arranged on the side of the climbing surface S1. The two second main chords 1 of the tower body are provided with a set of roller devices at the four corners of the climbing frame, and each set of roller devices includes two guide rollers 11 arranged perpendicular to each other and in rolling contact with the same main chord of the tower body. , each guide...

Embodiment 2

[0027] Example 2 as Figure 4 As shown, the difference from Embodiment 1 is only that the stopper assembly 4 is not provided.

[0028] Taking Example 1 as an example, during the specific operation, use the main hook to hoist the standard section 8 onto the introduction platform 5, and the frame of the standard section 8 is pressed on the standard section 8. Since the roller 7 is inclined, the standard section 8 will move down to the block assembly 4, blocked by the block assembly 4, and not moving. When the standard section 8 needs to be installed, start the rotating motor, and the rotation of the roller 7 will drive the standard section 8 to move and squeeze the slider. The thickness of the slider towards the side of the introduction surface S2 gradually becomes smaller, so the standard section 8 continues to push the slider, so that the spring is squeezed, the slider is pressed into the sliding cavity, and the standard section 8 smoothly moves from the introduction platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com