Hard box label paper code printing system

A technology for label paper and hard boxes, applied in typewriters, printing devices, printing, etc., can solve the problems of time-consuming and laborious, reducing the coding efficiency of hard box label paper, and poor maintenance of the label paper coding mechanism, so as to achieve good maintenance, The effect of improving coding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to facilitate the understanding of technical personnel.

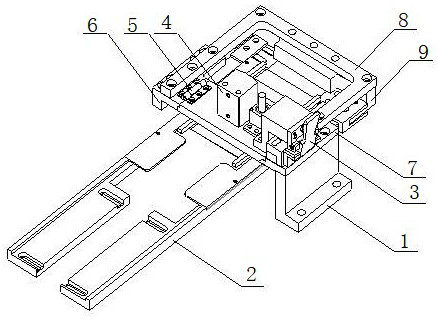

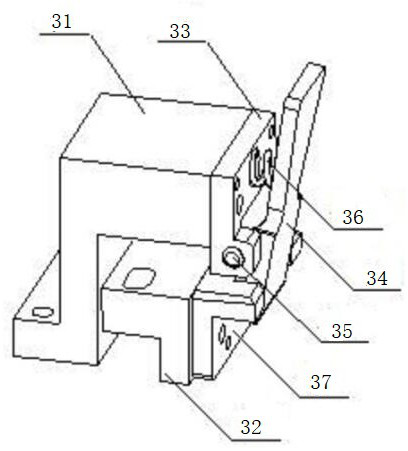

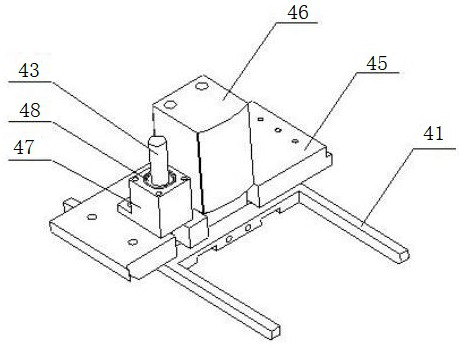

[0021] Such as Figure 1-4 As shown, the hard box label paper coding system includes a base 1, a connection system, a label paper push channel 2, a lock assembly 3, and a coding component 4; the base 1 is installed on the label paper push channel 2 One side, the connection system is installed on the base 1 and the label paper push channel 2, the coding component 4 is installed on the connection system through the loose-leaf hinge 5, and is located on the upper part of the label paper push channel 2, and the two sides of the loose-leaf hinge 5 are respectively installed on the On the basic connection plate 6 and the supporting plate 45, the flipping of 140° to 160° can b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap