An automatic high-efficiency grinding device

A grinding device and high-efficiency technology, which is applied in the field of automatic high-efficiency grinding devices, can solve the problems of different grinding sizes, low grinding efficiency, and difficult separation, and achieve the effects of increasing grinding precision, accelerating grinding efficiency, and increasing grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above objects, features and advantages of the present invention more obvious and comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

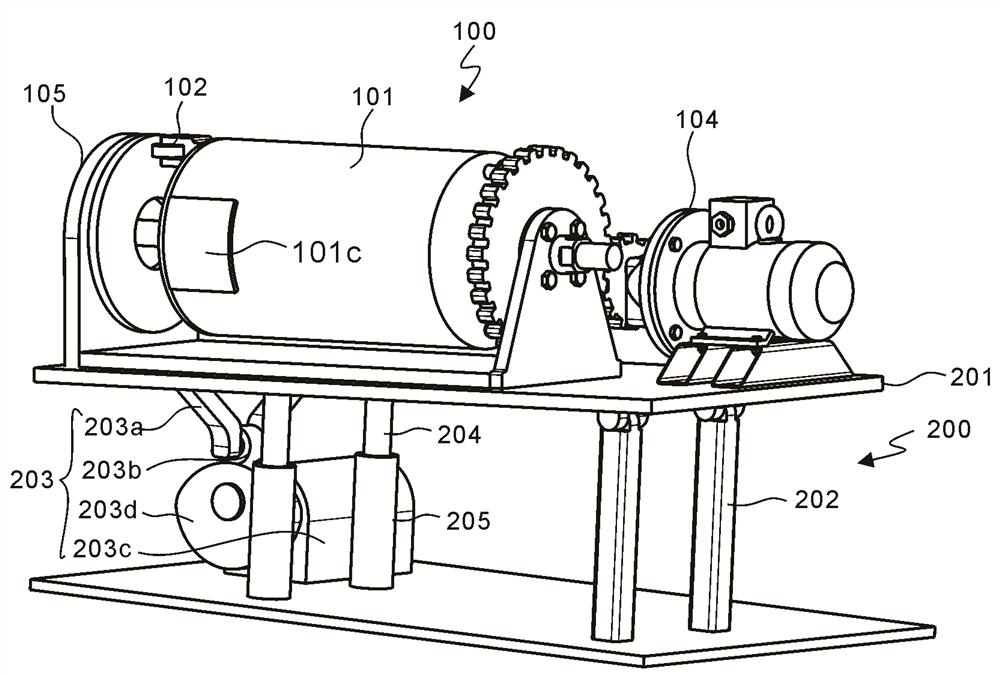

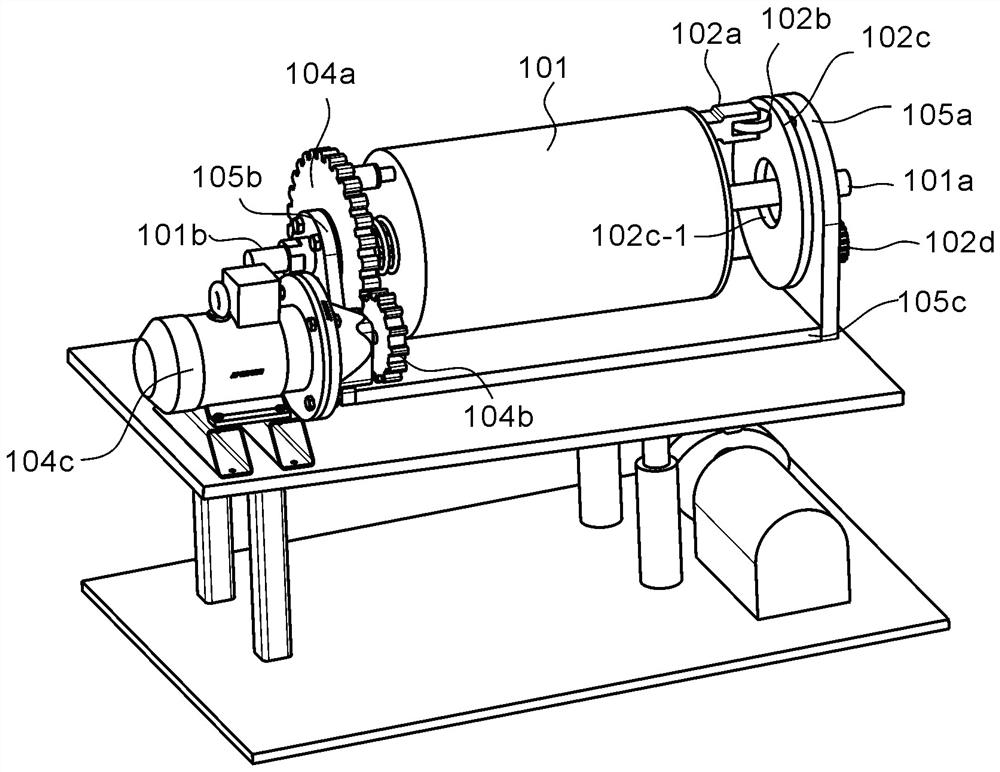

[0022] refer to Figure 1 to Figure 6 , which is the first embodiment of the present invention, this embodiment provides an automatic high-efficiency grinding device, the automatic high-efficiency grinding device includes a grinding unit 100 and a carrying unit 200, the grinding unit 100 is used to crush and grind raw materials, and the carrying unit 200 is set Below the grinding unit 100 , it is used to support the grinding unit 100 .

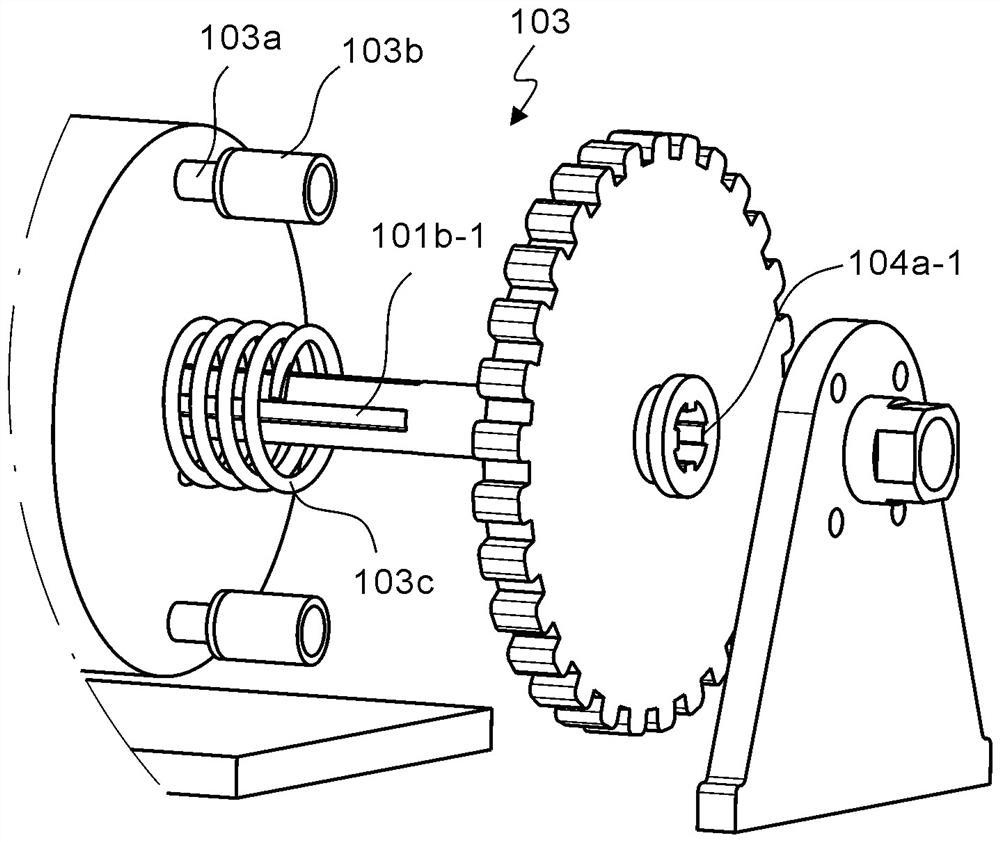

[0023] Specifically, the grinding unit 100 includes a grinding piece 101, an adjustment assembly 102 and an elastic piece 103 respectively disposed at both ends of the grinding piece 101, a first driving piece 104 that drives the grinding piece 101 to rotate, and a supporting piece 105 that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com