Inter-board vertical interconnection structure

A vertical interconnection and board-to-board technology, applied in the direction of connection, two-part connection device, and components of the connection device, etc., can solve the problems of inability to model simulation optimization, inability to use miniaturized 3D stacking modules, and large overall size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

[0021] Aiming at the deficiencies of the vertical interconnection structure of microwave signals between boards in the prior art, this application provides a new type of vertical interconnection structure between boards to realize three-dimensional stacked packaging modules on the basis of low cost, convenient assembly and use Microwave vertical interconnection between boards with small size and high transmission performance improves the microwave performance of the microwave module.

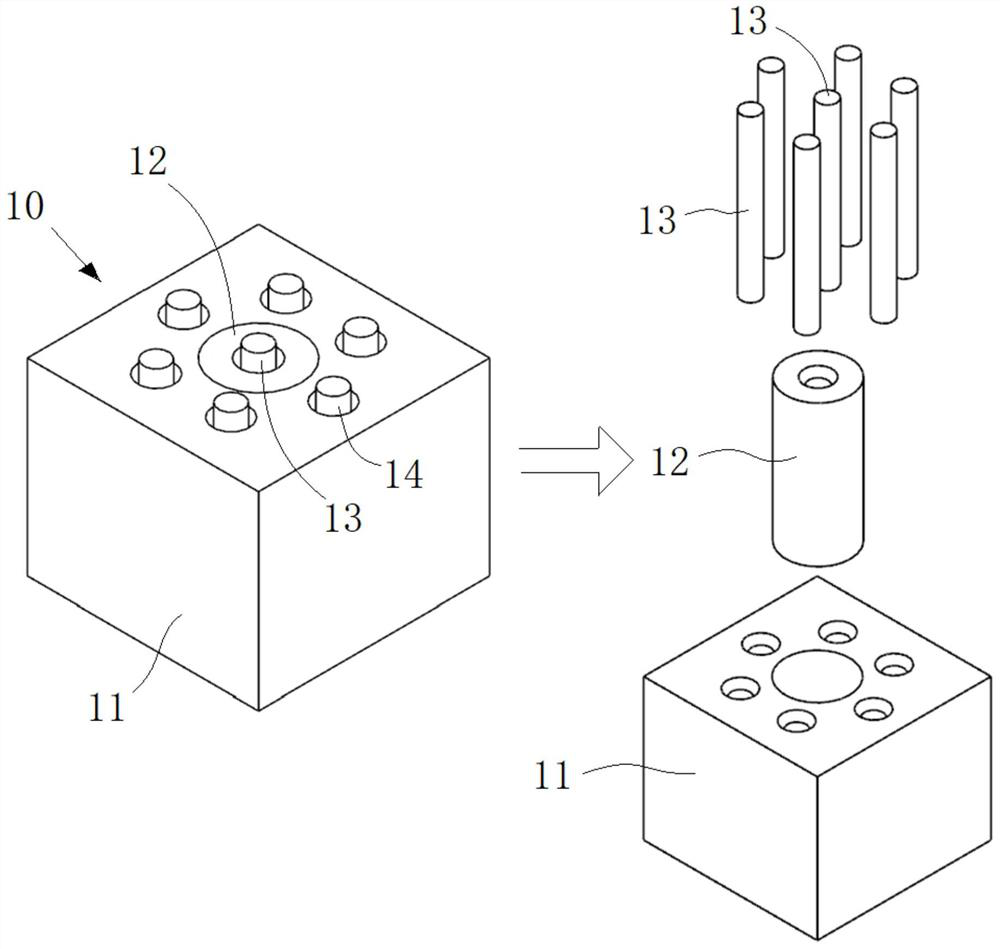

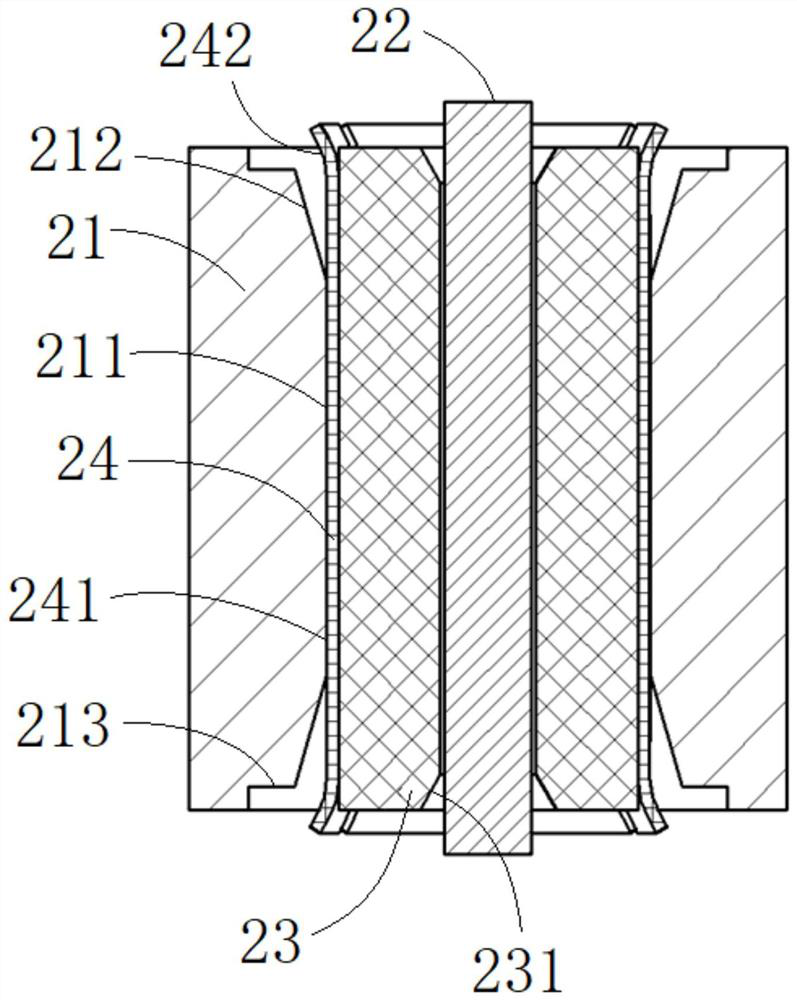

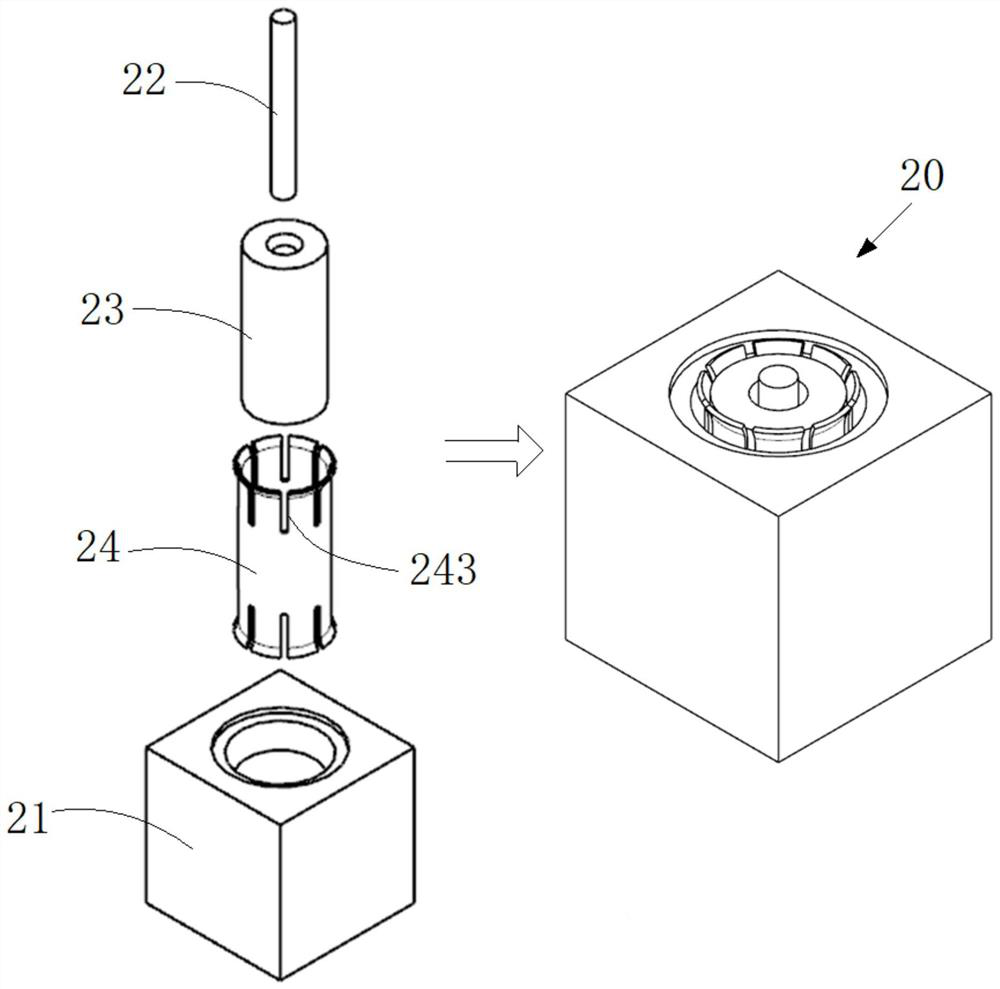

[0022] Such as figure 2 with image 3 As shown, the inter-board vertical interconnection structure 20 provided by the present application includes a metal frame 21 , a button 22 , a dielectric post 23 and an outer conductor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com