Pull-type fruit picking machine and fruit picking system

A picker and traction type technology, applied in harvesters, agricultural machinery and implements, solid separation and other directions, can solve the problems of affecting work efficiency, small fruit picking up, and costing manpower and material resources, so as to improve work efficiency and increase picking up. volume, the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

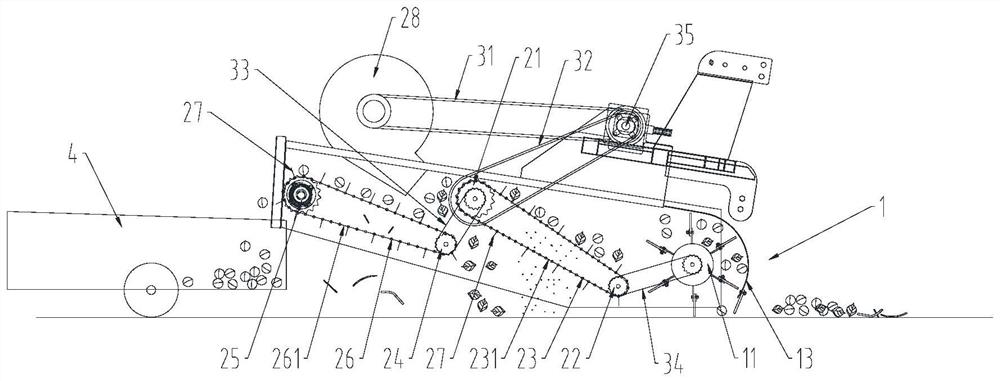

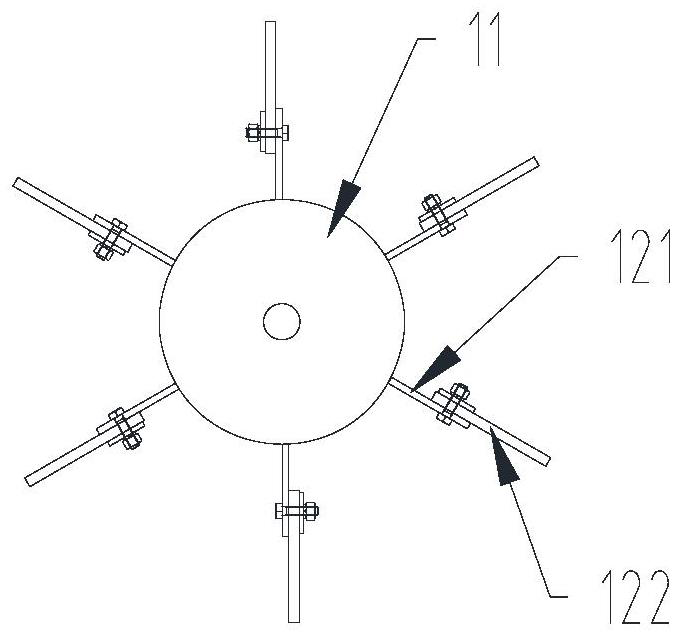

[0058] As an embodiment, the transmission part also includes a fourth transmission part 34, the first driven wheel 22 is located between the first driving wheel set 21 and the pick-up part 1, and the pick-up part 1 connects with the first driven wheel 22 through the fourth transmission part 34. connected, so that the first driven wheel 22 drives the pick-up part 1 to rotate in the vertical plane through the fourth transmission part 34, and by setting the fourth transmission, it can be realized to stably drive the pick-up part 1 to run, and then pick up the ground. fruit.

[0059] As another embodiment, the pick-up part 1 is connected to the gearbox 35 through the fourth transmission part 34, so that the second driven wheel 25 drives the pick-up part 1 to rotate in the vertical plane through the gearbox 35, and it can also realize stable Drive picking up part 1 to run, and then pick up the fruit on the ground.

[0060] Further, the fourth transmission member 34 is a chain, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com