Smashing device for artificial diamond production

A technology of artificial diamond and storage rack, which is applied in the field of diamond smashing, can solve the problems of energy consumption and unsatisfactory, and achieve the effect of avoiding large energy consumption and insufficient impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

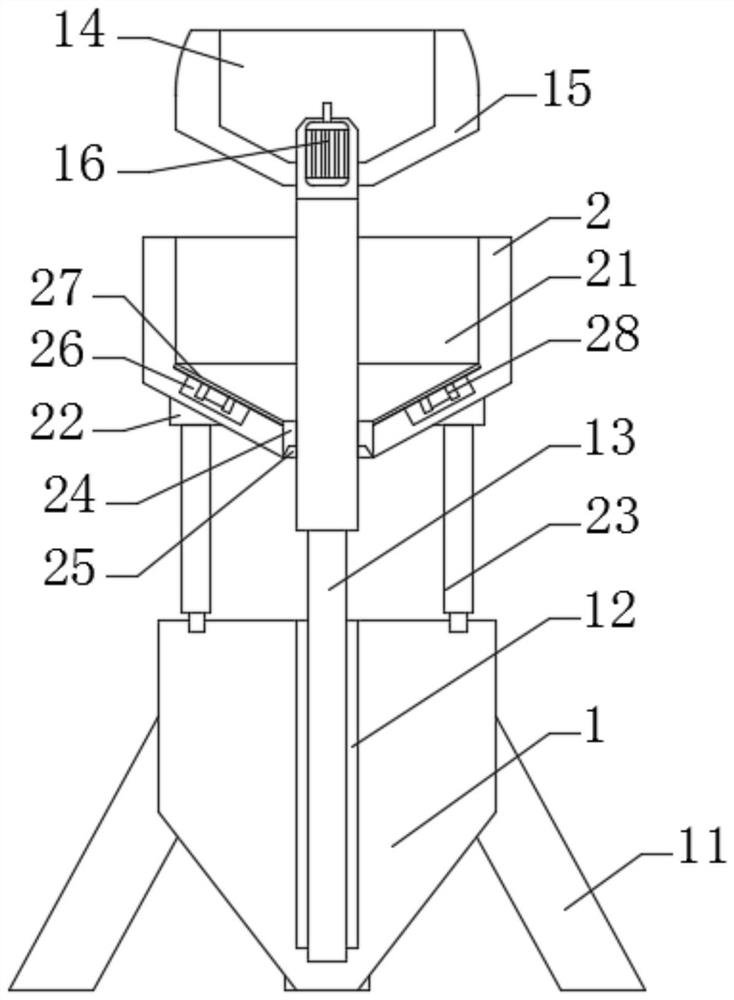

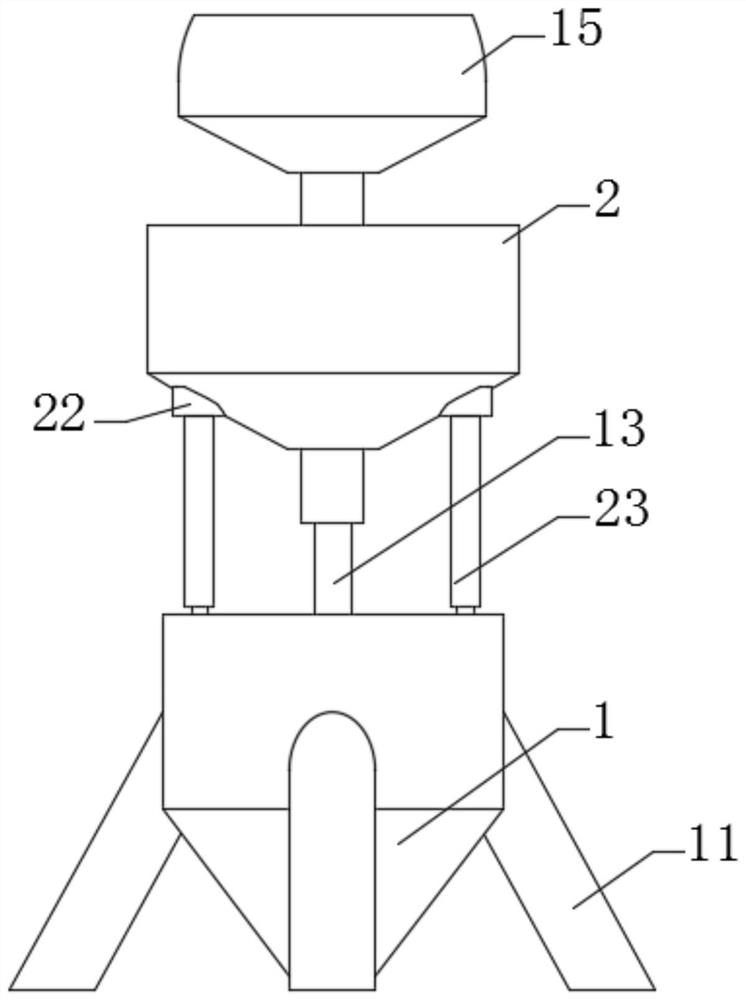

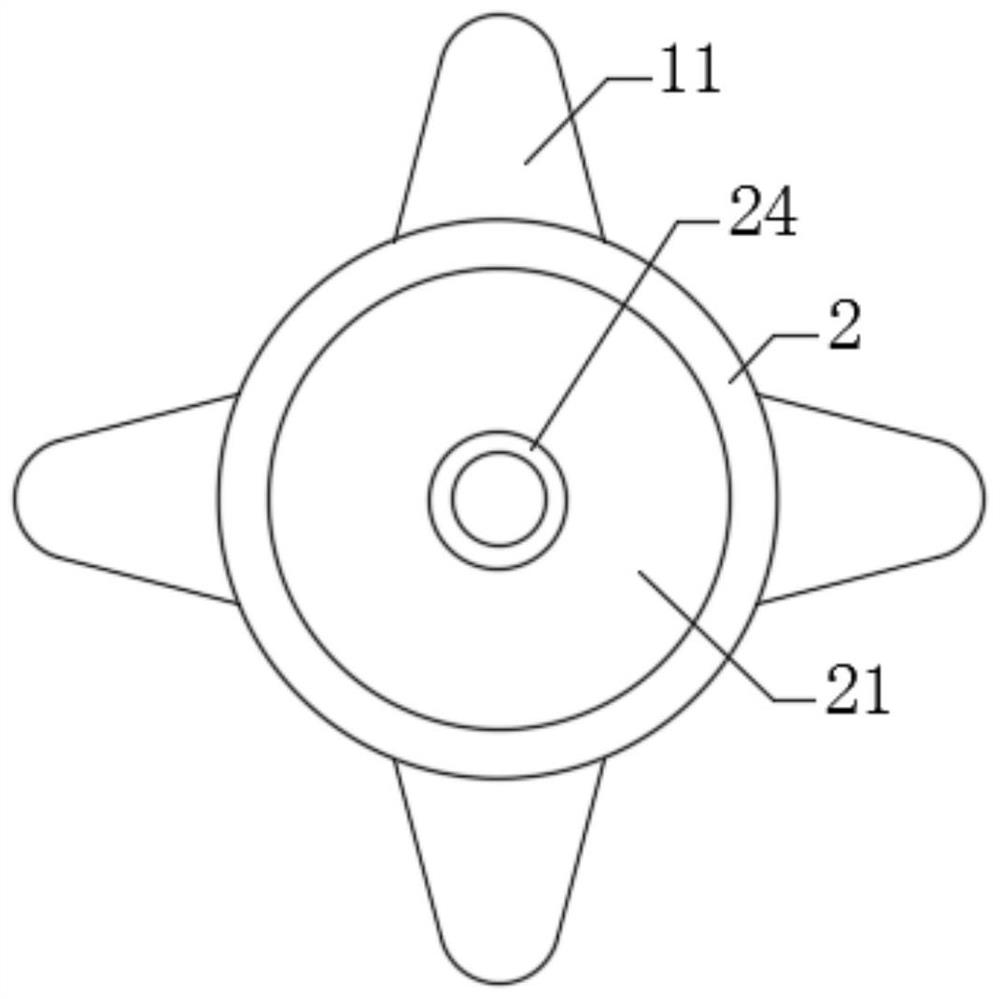

[0023] Please refer to figure 1 , figure 2 and image 3 ,in, figure 1 It is a schematic diagram of the overall front view sectional structure of the present invention; figure 2 It is a schematic structural diagram of the overall front view of the present invention; image 3 It is a schematic view of the structure of the storage frame of the present invention; a specifically described smashing device for artificial diamond production includes: a bottom frame 1, the center of the upper surface of the bottom frame 1 is provided with a storage groove 12, the The lower surface of the center of the storage tank 12 is threaded with a first electric telescopic rod 13, the top of the first electric telescopic rod 13 is equipped with a motor 16 through a bolt, and the power output end of the motor 16 is mounted with a top frame 14 through a bolt. , The outer periphery of the top frame 14 is welded with a steel sleeve 15 .

[0024] Wherein, through the setting of the steel sleeve ...

Embodiment 2

[0031] Please refer to figure 1 , figure 2 and image 3 ,in, figure 1 It is a schematic diagram of the overall front view sectional structure of the present invention; figure 2 It is a schematic structural diagram of the overall front view of the present invention; image 3 It is a schematic view of the structure of the storage frame of the present invention; a specifically described smashing device for artificial diamond production includes: a bottom frame 1, the center of the upper surface of the bottom frame 1 is provided with a storage groove 12, the The lower surface of the center of the storage tank 12 is threaded with a first electric telescopic rod 13, the top of the first electric telescopic rod 13 is equipped with a motor 16 through a bolt, and the power output end of the motor 16 is mounted with a top frame 14 through a bolt. , The outer periphery of the top frame 14 is welded with a steel sleeve 15 .

[0032] Wherein, through the setting of the steel sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com