A 3D printer that facilitates material removal and prevents clogging

A technology of 3D printers and print heads, which is applied in the direction of additive processing, improvement of process efficiency, manufacturing auxiliary devices, etc. It can solve the problems of automatic unblocking, inconvenient use, and poor functionality, so as to improve convenience and use effect, effect before functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

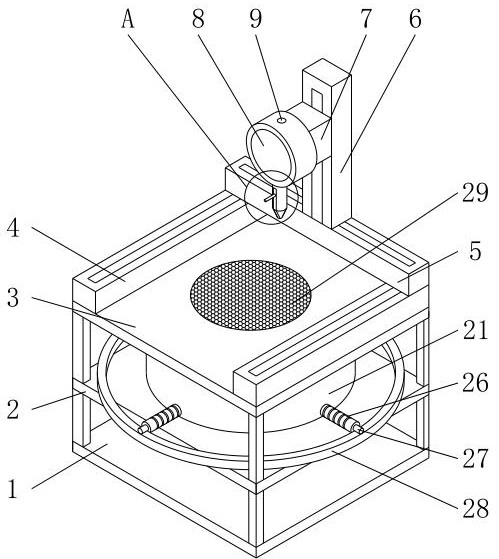

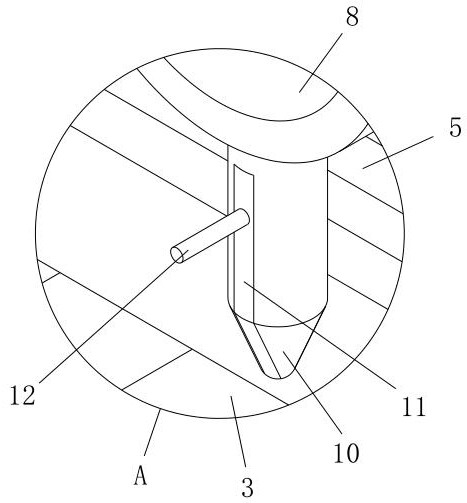

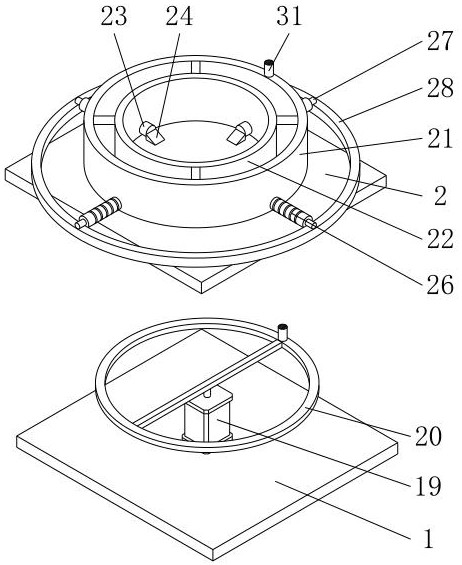

[0036] Such as Figure 1-Figure 10 As shown, a 3D printer that is convenient for removing materials and preventing clogging includes a first support seat 1, a second support seat 2, a first electric slide seat 4 and a print head 10, and a top of the first support seat 1 is fixedly arranged The second support seat 2, the top of the second support seat 2 is welded with a support plate 3, the left and right sides of the support plate 3 are fixedly installed with the first electric slide seat 4, and the surface of the first electric slide seat 4 is installed with the second Two electric slides 5, the third electric slide 6 is installed in the middle of the second electric slide 5, the front end of the third electric slide 6 is slidably insta...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap