Pneumatic muscle and hyperelastic rod combined continuum snakelike arm

A pneumatic muscle and superelastic technology, applied in the field of robotic arms, can solve the problems of low end precision, gap between output precision and application requirements, etc., and achieve the effect of improving output force and motion precision, variable and controllable stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

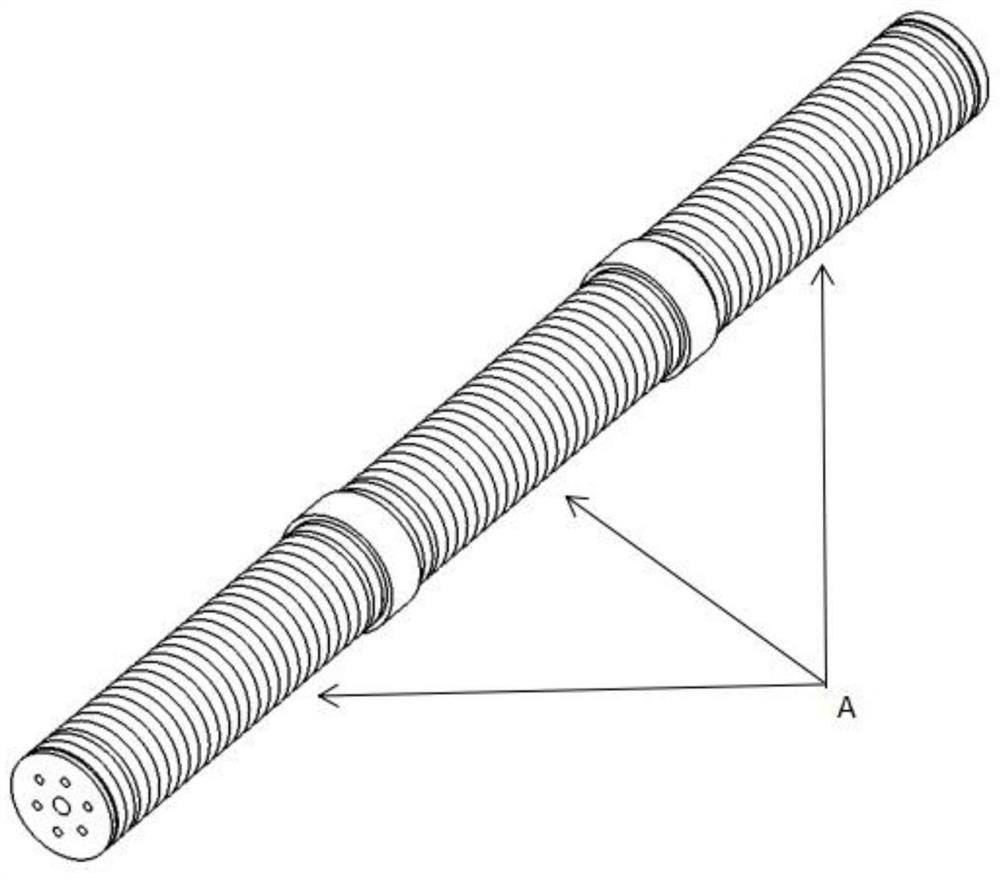

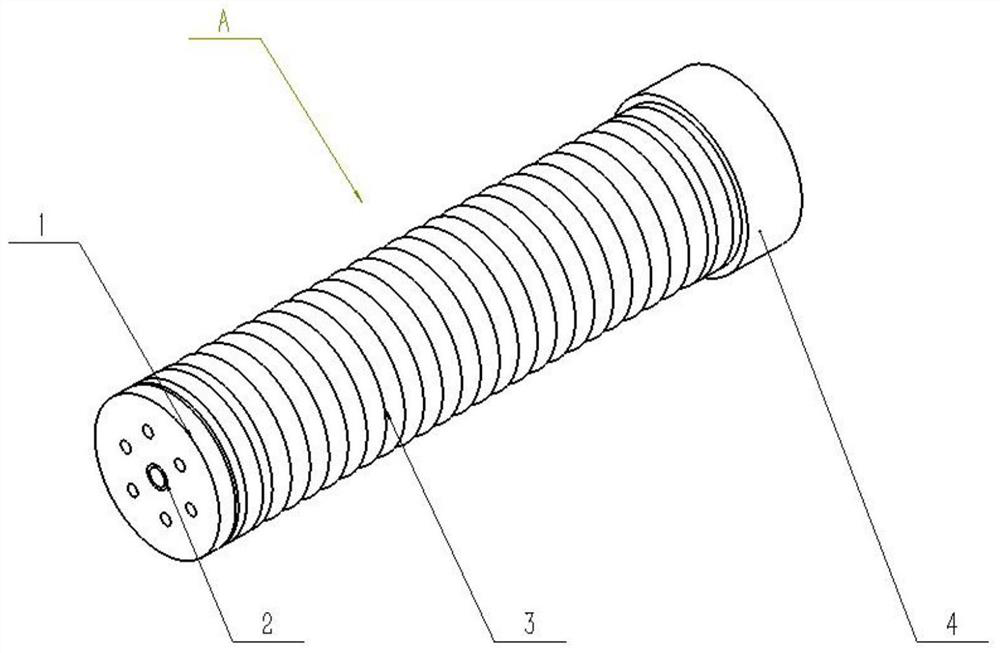

[0028] Such as figure 1 As shown, the continuum serpentine arm combined with the pneumatic muscle and the superelastic rod provided in this embodiment includes several detachably connected variable stiffness drivers A; as shown in FIG. figure 2 As shown, the variable stiffness driver includes a soft end plate 1 , a superelastic rod mechanism and a limiting triangular end plate 2 , a soft pneumatic unit 3 , and a connecting sleeve 4 .

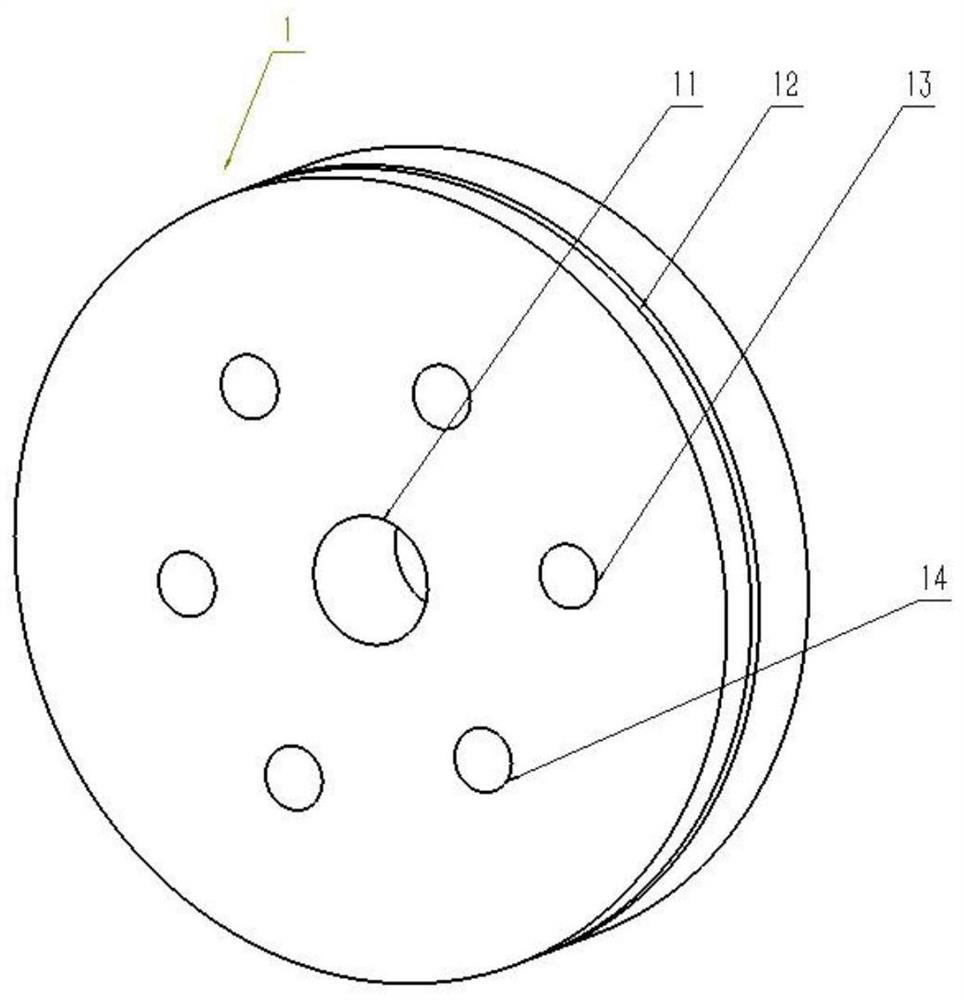

[0029] Such as figure 2 , image 3 As shown, the soft end plate 1 is a ring plate, which is bonded to both ends of the soft pneumatic unit, and a main rod through hole 11 is provided at the center of the soft body for the superelastic main rod to pass through and then connected to the next variable stiffness driver. It can reduce its own weight; there are 6 through holes arranged in a circular array around the through holes on the end plate of the soft body. The control rod through hole 13 is used for the control rod to pass through and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com