Pressing device for metal bookmark production line

A production line and bookmark technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of destroying the overall appearance of the pattern, easy to stick to the tool, and high stickiness of copper parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

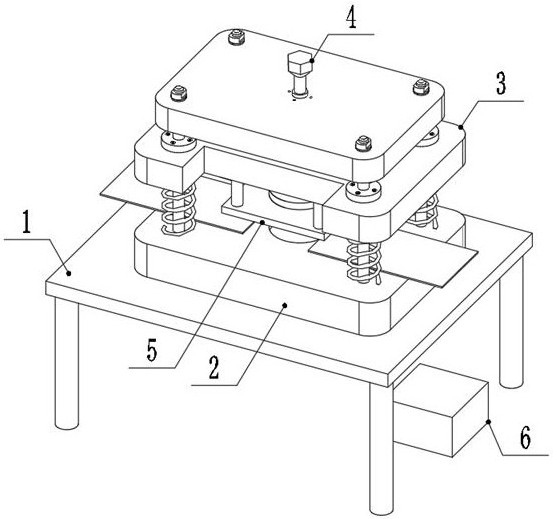

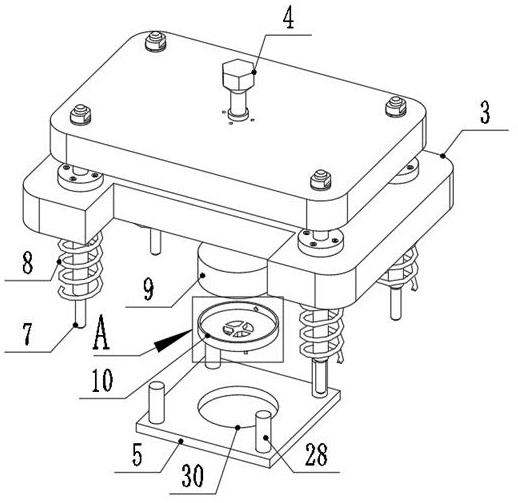

[0045] see Figure 1-4 , the present invention provides a technical solution: a pressing device for a metal bookmark production line, comprising a support part 1, a container 6 and a mold body, wherein:

[0046] The main body of the mold is fixed on the upper side of the support part 1, the container 6 is arranged around the support part 1, and the container 6 is provided with a cooling liquid;

[0047] The mold body includes a lower mold body 2, a connecting assembly, and an upper mold assembly, wherein:

[0048] The lower die body 2 is fixed with the support portion 1, and the lower die body 2 is provided with a pressure-bearing area, which is used to adapt to the deformation of the material during punching;

[0049] The connecting assembly includes a guide member 7 and a first spring 8, the guide member 7 is fixed on the upper side of the lower die main body 2, and the first spring 8 is sleeved on the outer ring of the guide member 7;

[0050] The upper die assembly inclu...

Embodiment 2

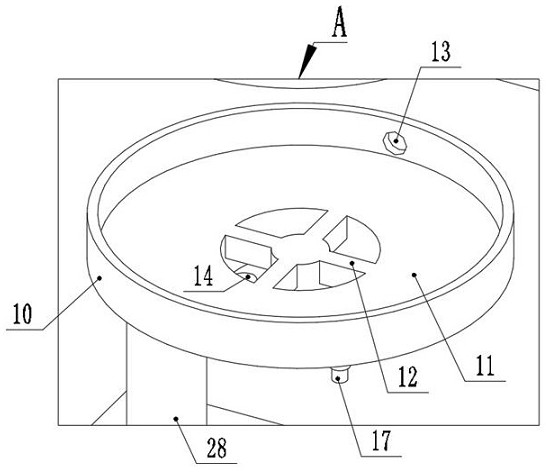

[0059] like Figure 3-5 , the structure of this embodiment is basically the same as that of the first embodiment, the difference is that the following structure is added on the basis of the first embodiment: an interval cooling assembly is included, and the interval cooling assembly includes a first chamber 21, a plug body 20, and a one-way valve 18. , the fifth spring 32 and the circuit 31, where:

[0060] The first chamber 21 is located at the lower end of the reinforcing member 12 , the first chamber 21 is fixed with the fifth spring 32 , the lower end of the fifth spring 32 is fixed with the plug body 20 , and the upper end of the plug body 20 is slidably connected with the inner wall of the first chamber 21 , the lower end of the plug body 20 is spherical, and the spherical shape is matched with the liquid outlet hole 14;

[0061] A one-way valve 18 is provided in the connecting pipeline between the accommodating chamber 11 and the container 6;

[0062] The circuit 31 i...

Embodiment 3

[0069] like Figure 3-4 , the structure of this embodiment is basically the same as that of the second embodiment, the difference is that the following structure is added on the basis of the second embodiment: the marking part 17 is included, wherein:

[0070] The marking part 17 is located at the lower end of the stamping part 10, the marking part 17 is divided into multiple layers and has a telescopic structure, and marking pigments are provided on the outer side of the lower end of the marking part 17 of each layer;

[0071] In this embodiment, the pressed metal material is marked to confirm the state of pressing, which is convenient for subsequent inspection and determination of the timing of tool replacement;

[0072] Specifically, in this embodiment, it is determined by setting that the marking portion 17 is in contact with the metal material when the metal material is press-molded. Under normal circumstances, the marking portion 17 is only in contact with the inner laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com