Vibration noise test system

A test system, noise technology, applied in the direction of vibration test, machine/structural component test, measuring device, etc., can solve the problem of reducing the accuracy of test results, and achieve the effect of avoiding noise reflection and high test flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the technical problems solved by the present invention, the technical solutions adopted and the technical effects achieved more clearly, the technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, the accompanying drawings only show some but not all of the parts related to the present invention.

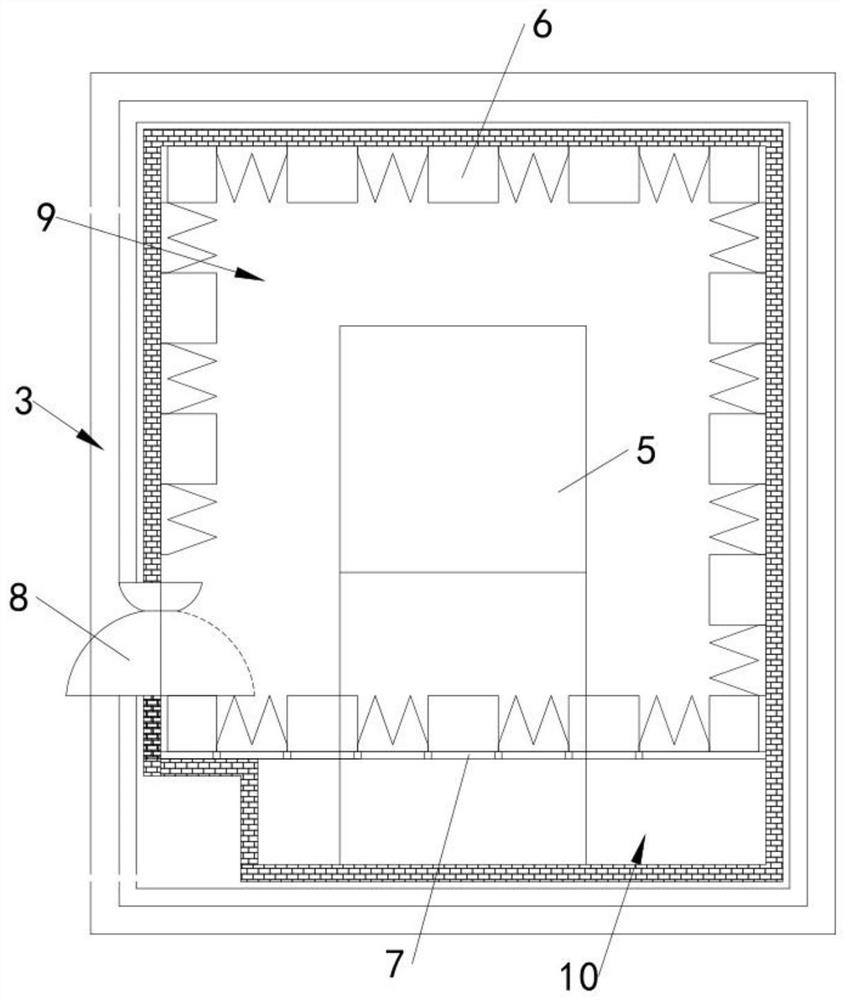

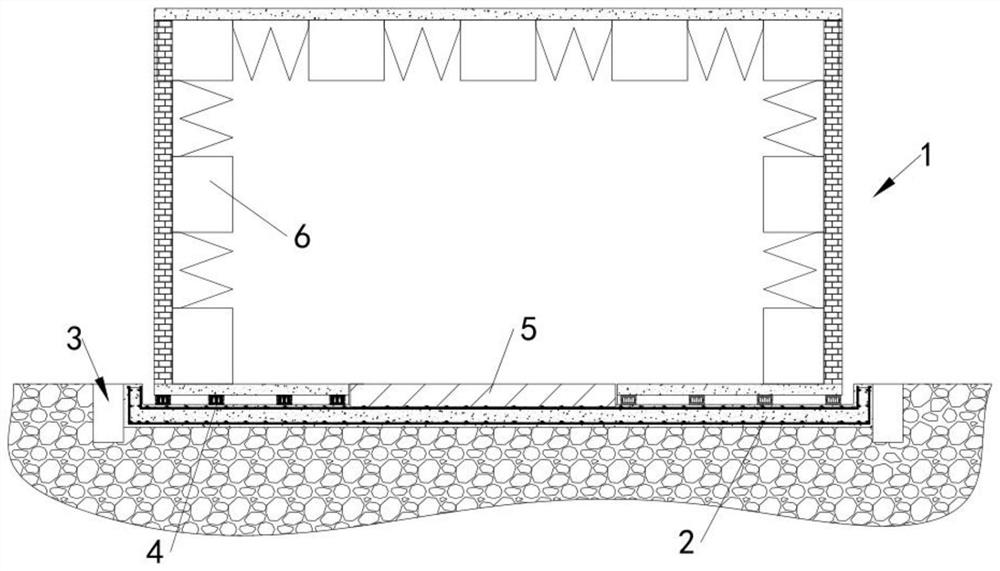

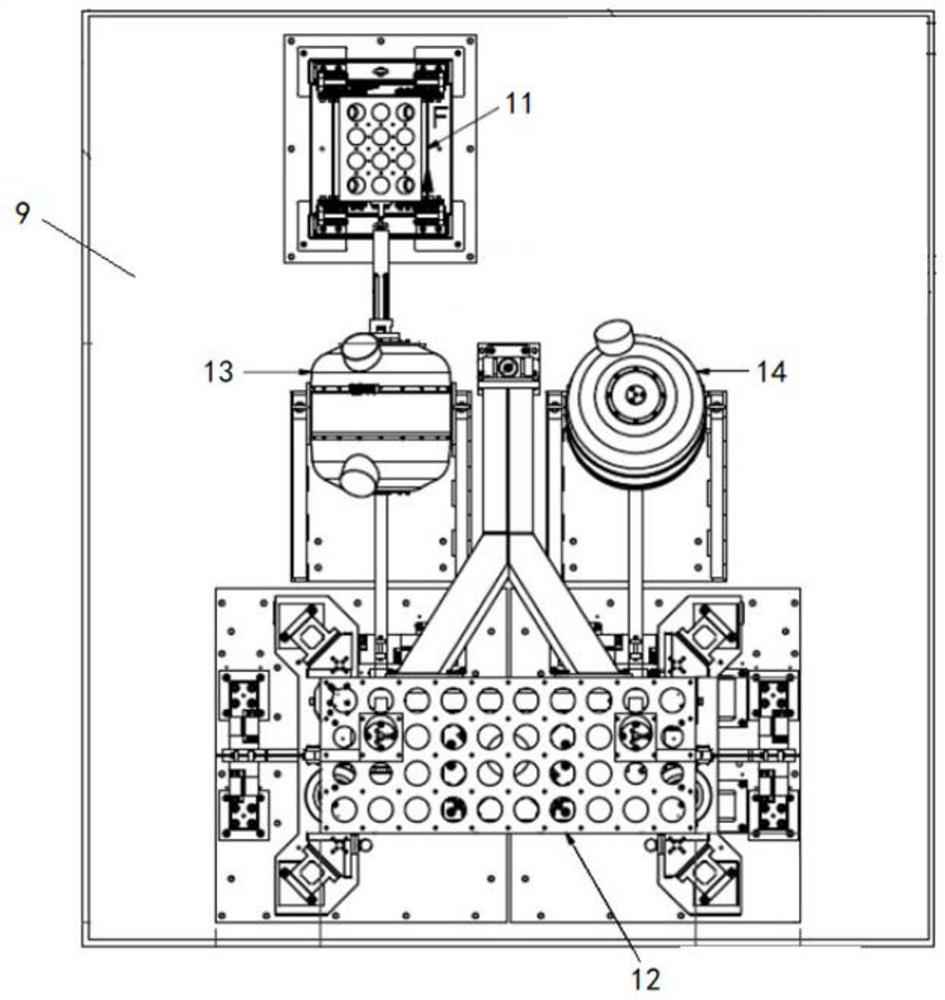

[0049] like Figure 1 to Figure 4 As shown, this embodiment provides a vibration and noise testing system for performing vibration and noise testing on a test product. In this embodiment, the test products mainly refer to auto parts, such as front and rear seats, instrument panel, center console, body, front and rear doors, brake assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com