Conveyor lubricating and cleaning device

A technology for cleaning devices and conveyors, applied in the field of conveyors, which can solve problems such as omissions, affecting the normal use of conveyors, equipment wear, etc., and achieve the effect of avoiding oil shortage wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

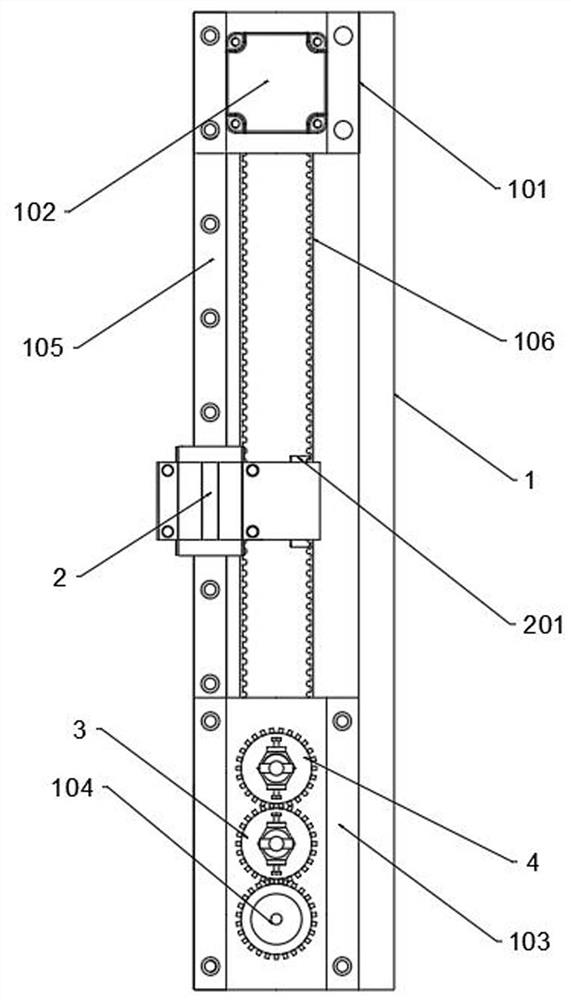

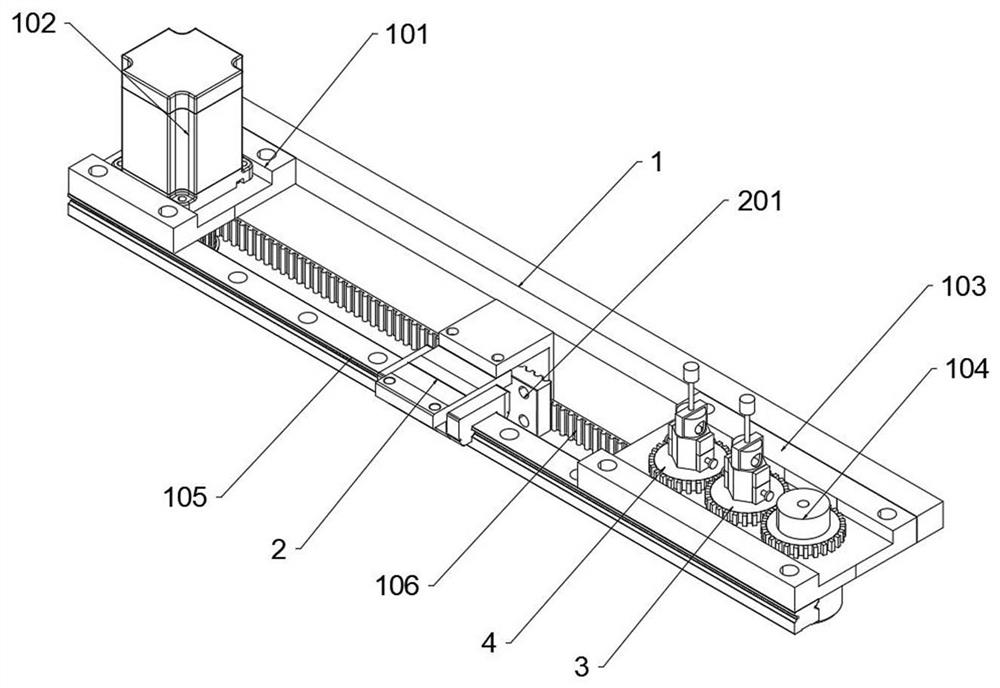

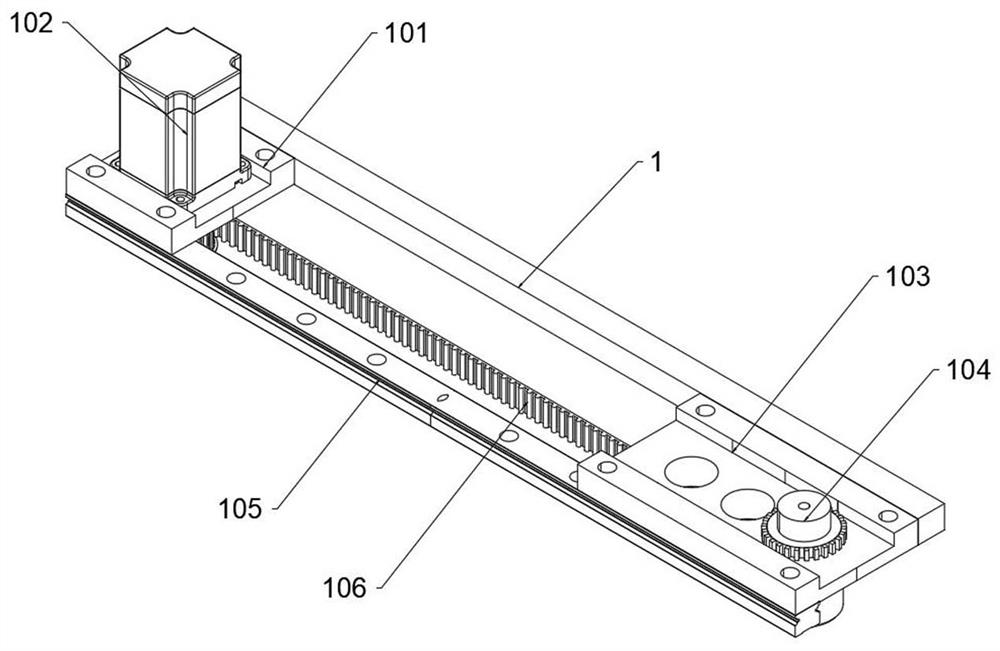

[0033] as attached figure 1 to the attached Figure 8 shown:

[0034] The present invention provides a conveyor lubrication and cleaning device, comprising: a bracket 1; a main seat 101 is fixedly connected at the left rear end of the bracket 1, and a motor 102 is fixedly connected at the top middle position of the main seat 101, and the lower rotating shaft of the motor 102 is arranged There is a transmission wheel, an auxiliary seat 103 is fixedly connected to the left front end of the bracket 1, and three through holes are opened in the middle position of the top of the auxiliary seat 103, and each through hole is provided with a bearing. The left end of the auxiliary seat 103 is connected to the slide rail 105. The right front end position is fixedly connected, and the right rear end position of the slide rail 105 is fixedly connected with the left end position of the main seat 101 .

[0035]The auxiliary shaft 104 is rotatably connected to the inner side of the bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com