Control method of crankshaft heating belt of multisplit air conditioning machine

A control method and heating belt technology, applied in heating methods, lighting and heating equipment, heating and ventilation control systems, etc., to achieve the effects of reducing energy consumption, improving the use effect and reliability of operation, and avoiding oil shortage and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

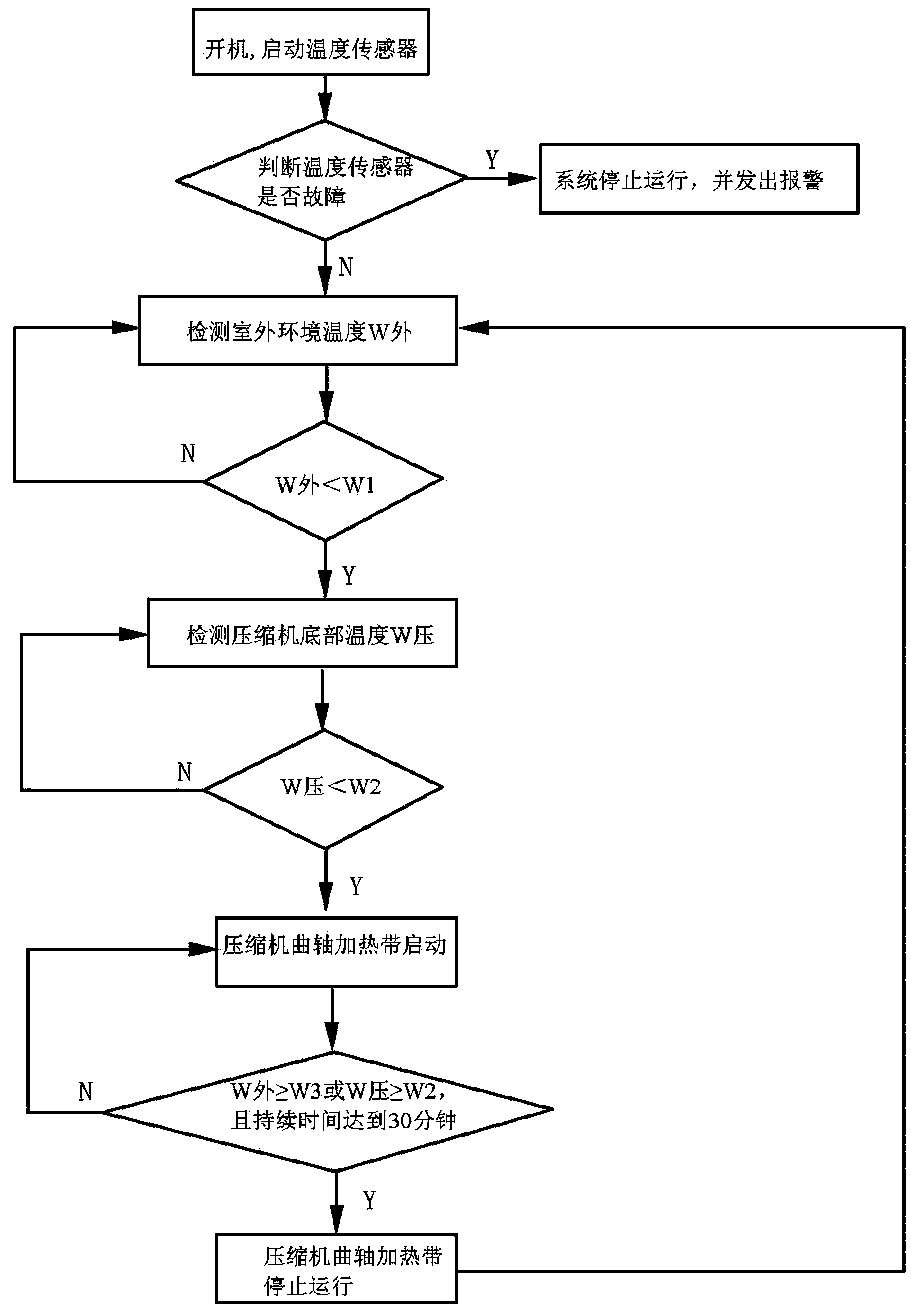

[0018] Such as figure 1 shown.

[0019] A control method for a multi-connected crankshaft heating belt, comprising a first temperature sensor for detecting the outdoor temperature and a second temperature sensor for detecting the temperature at the bottom of the compressor, including the following steps:

[0020] 1) Power on, start the first temperature sensor and the second temperature sensor; set the temperature critical value W1, W2 and W3 at the same time; where: W1

[0021] 2) Judging whether the first temperature sensor and the second temperature sensor are normal; if any one of them fails, the entire system stops running and an alarm is issued;

[0022] 3) The system collects the first temperature sensor to detect the outdoor ambient temperature W 外 ;

[0023] 4) If W 外 压 ; Otherwise,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com