Method for object treatment

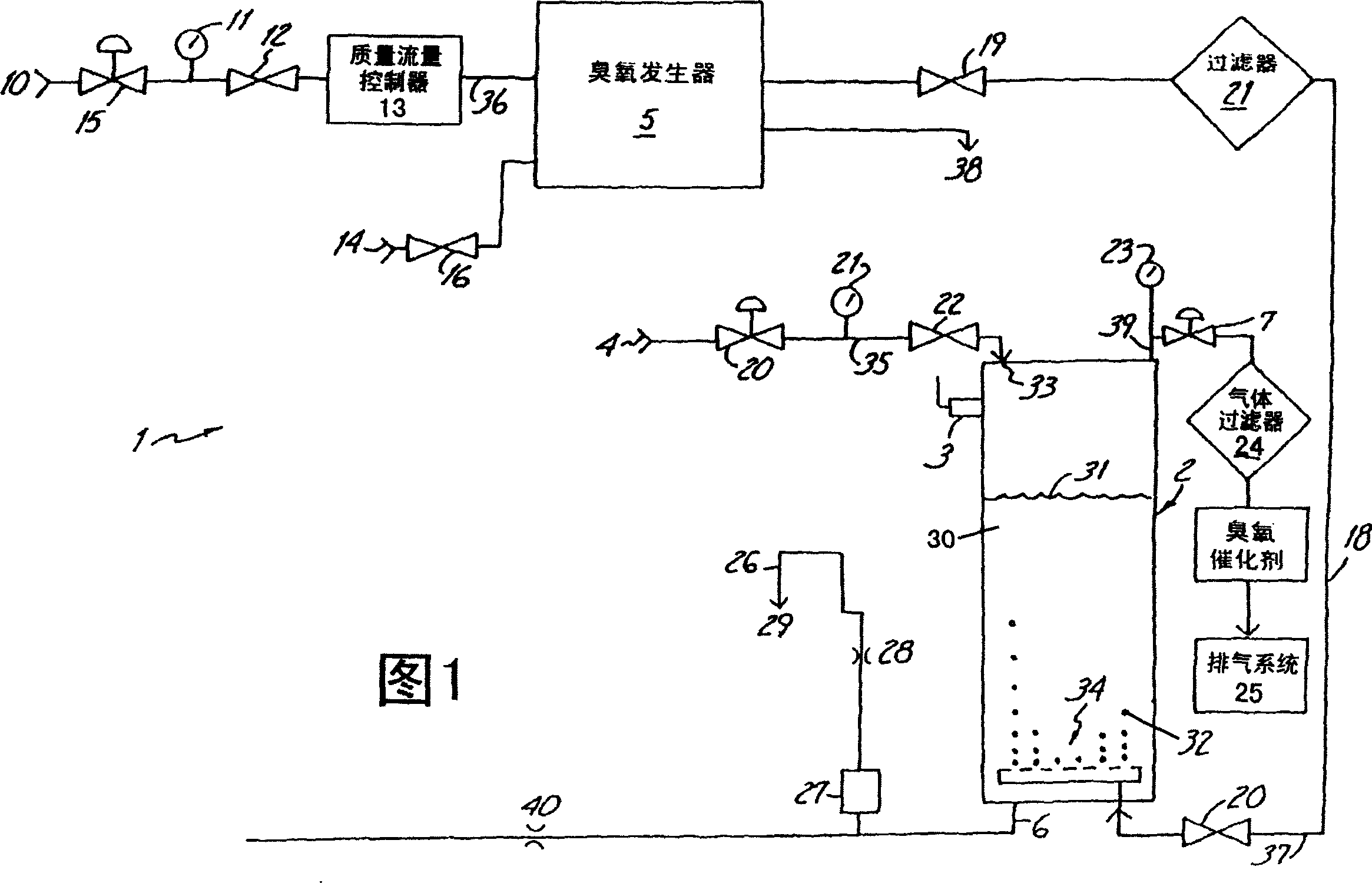

A technology for objects and mixtures, which can be used in cleaning methods using liquids, cleaning methods using gas flow, mixing methods, etc., and can solve the problems of lack of disclosure, high cost, and use of large amounts of ozone.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

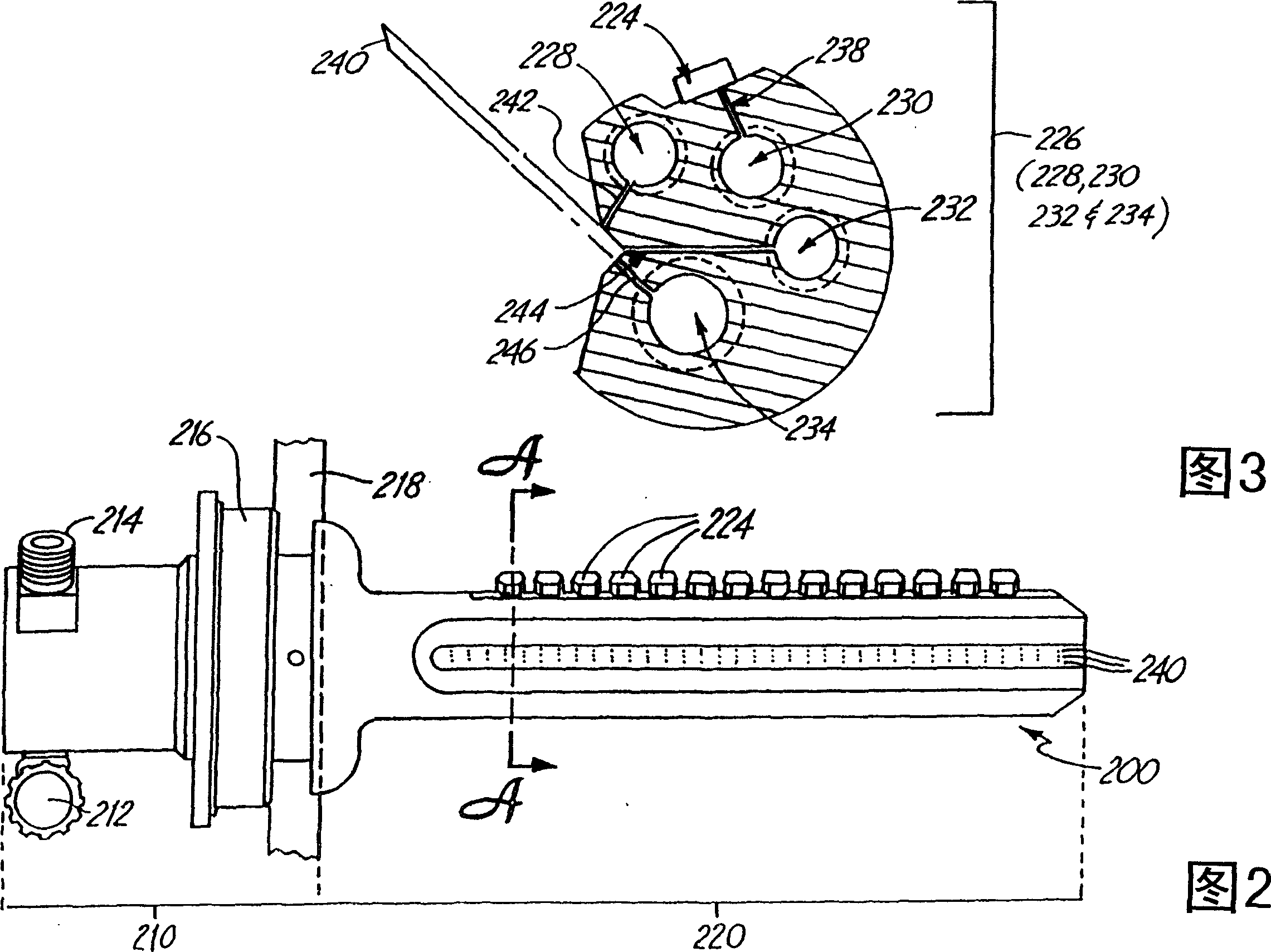

[0063] This experiment was performed to show the effect of different dispensing techniques on the amount of ozone retained in the aqueous ozone solution at the point of use. The effect on the efficiency of the dispensing method was evaluated as the following parameters were varied: atomizing gas pressure, nozzle design, and mixture flow through the nozzle.

[0064] The initial ozone concentration was determined by withdrawing a side stream of ozone water from a pressurized vessel and measuring the dissolved ozone concentration using an industrially available sensor. A second sensor is used to measure the dissolved ozone concentration after the liquid has been dispensed through the spray column by collecting the liquid and funneling it into the sensor. The percentage concentration of ozone remaining in solution is determined by the formula [O 3最终 ] / [O 3初始 ]×100 to calculate, where the symbol [O 3 ] represents the concentration of ozone dissolved in water.

[0065] Atomizati...

Embodiment 2

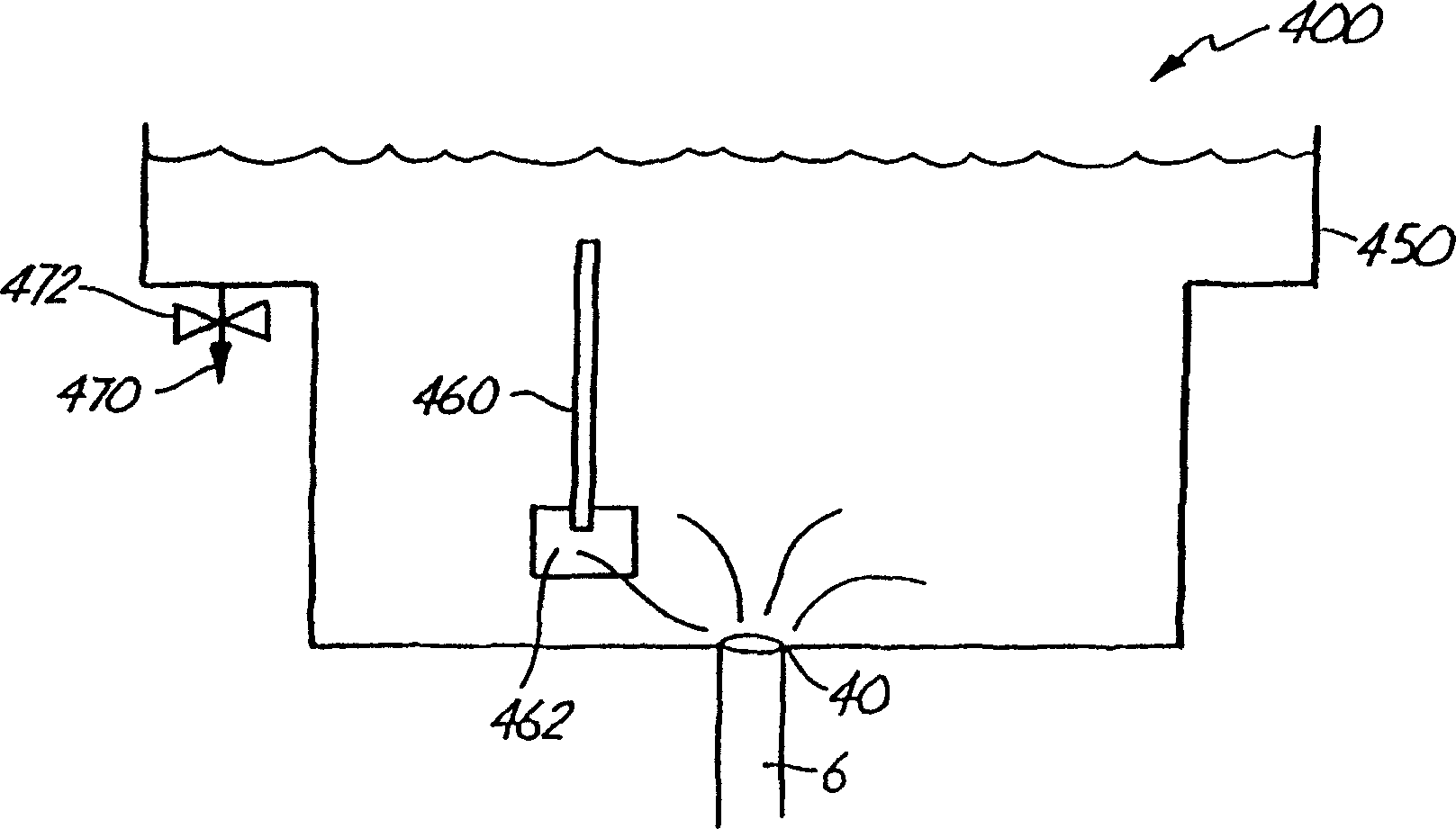

[0073] This experiment was performed to show the effect of increased ozone concentration on the oxidation of silicon surfaces. In this experiment, the dispensing technique and all other parameters were held constant and only the pressure of the pressurized vessel was varied. As the pressure changes, the concentration of ozone dissolved in the water changes, thus changing the time required to fully oxidize the silicon surface.

[0074] Specifically, when the ozone generator is set to low power and the pressure of the pressurized container is kept at 0 psi (0 kilopascals), 1.0 ppm of ozone water is produced; when the ozone generator is set to high power and the pressure of the pressurized container is kept at When 0psi (0 kilopascals), produce the ozone water of 10.0ppm; And when the ozone generator is set to high power and keep the pressure of the pressurized container at 25psi (172.4 kilopascals), produce the ozone water of 50.0ppm; Then the ozone Water is dispensed onto the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com