Ammonium and rare enrth ion exchange method of molecular sieve

A rare earth ion and ion exchange technology, applied in the field of ion exchange of molecular sieves, can solve the problems of easy clogging of filter cloth mesh, and achieve the effect of high degree of automation and high efficiency of exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

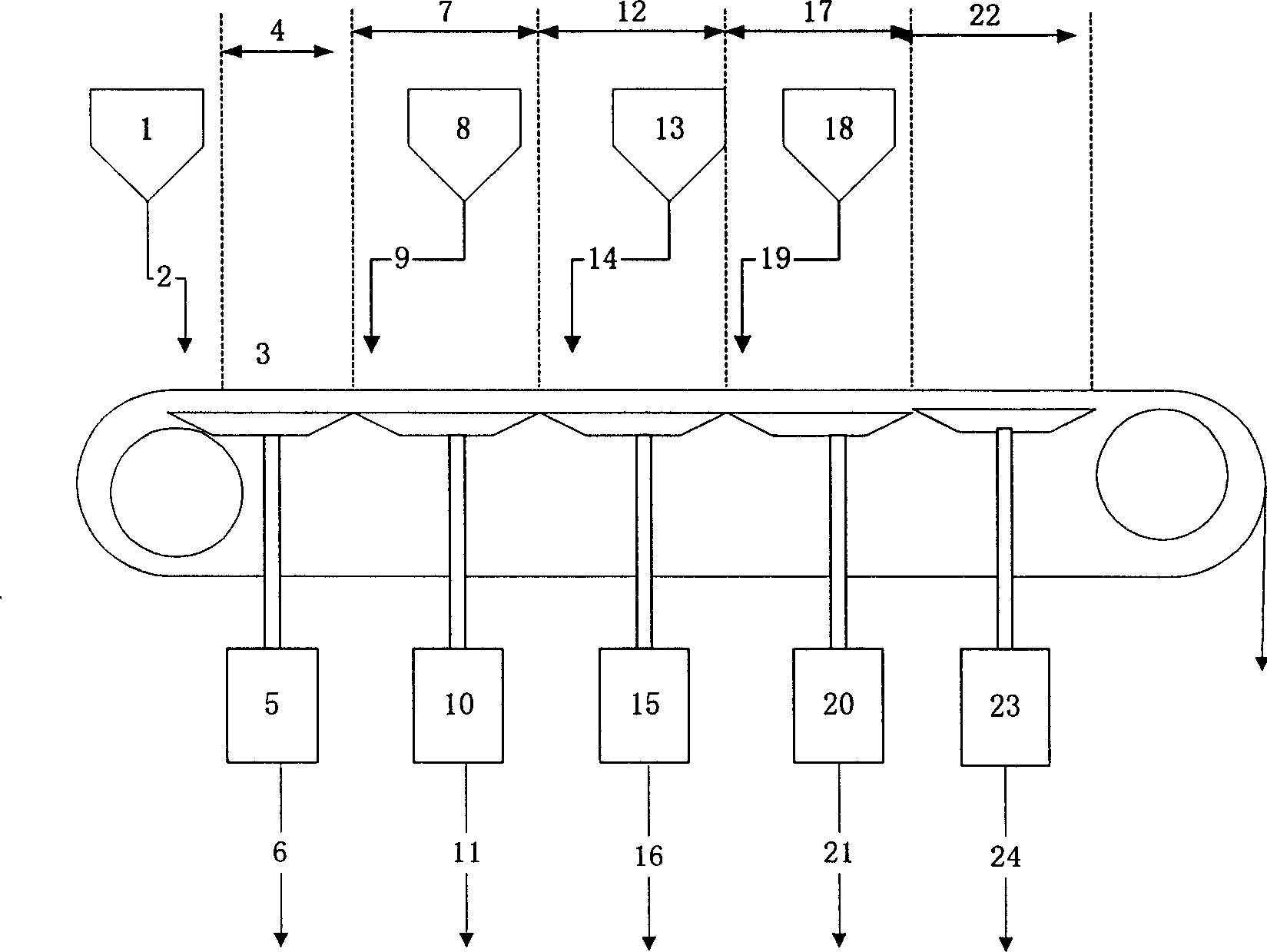

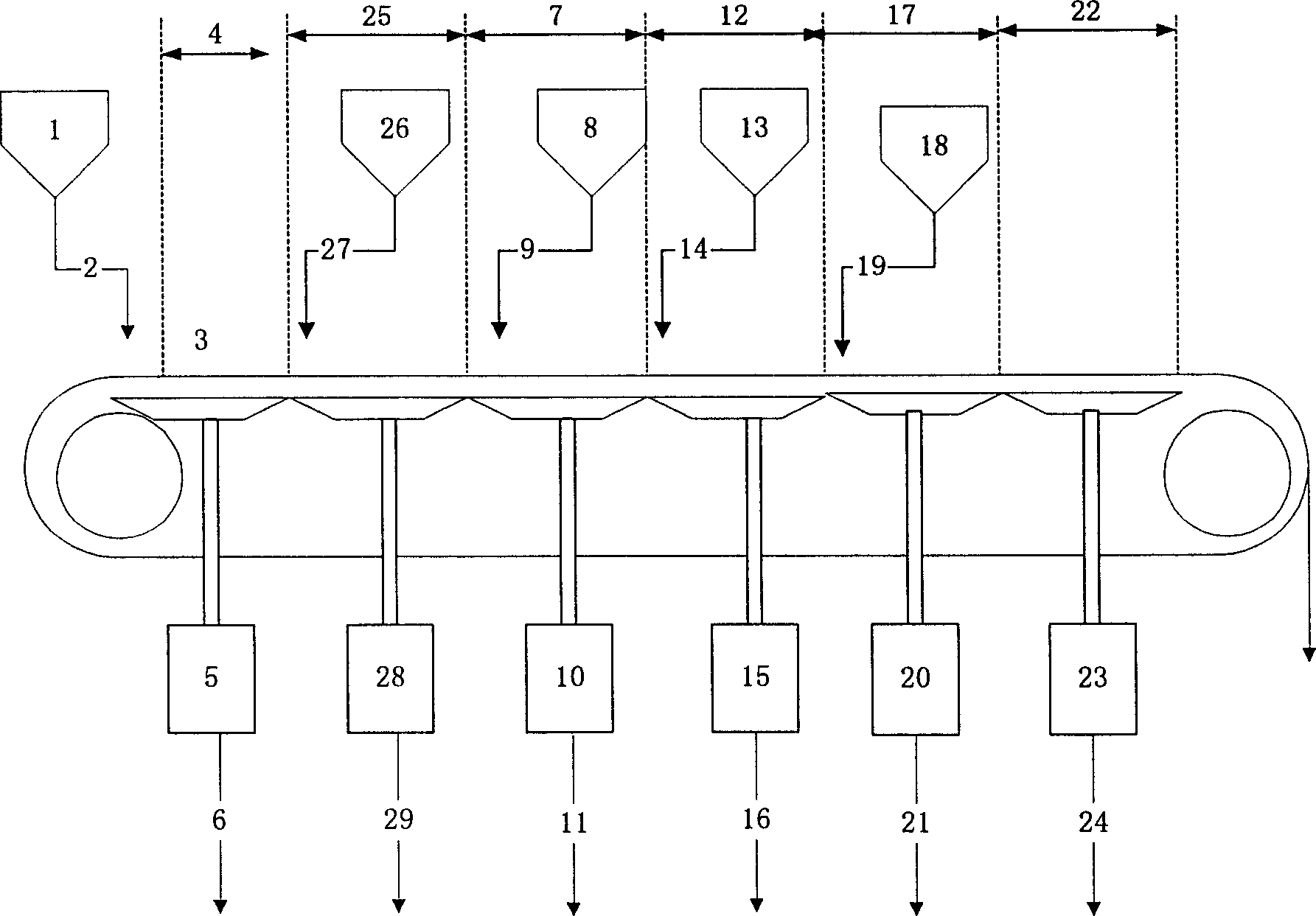

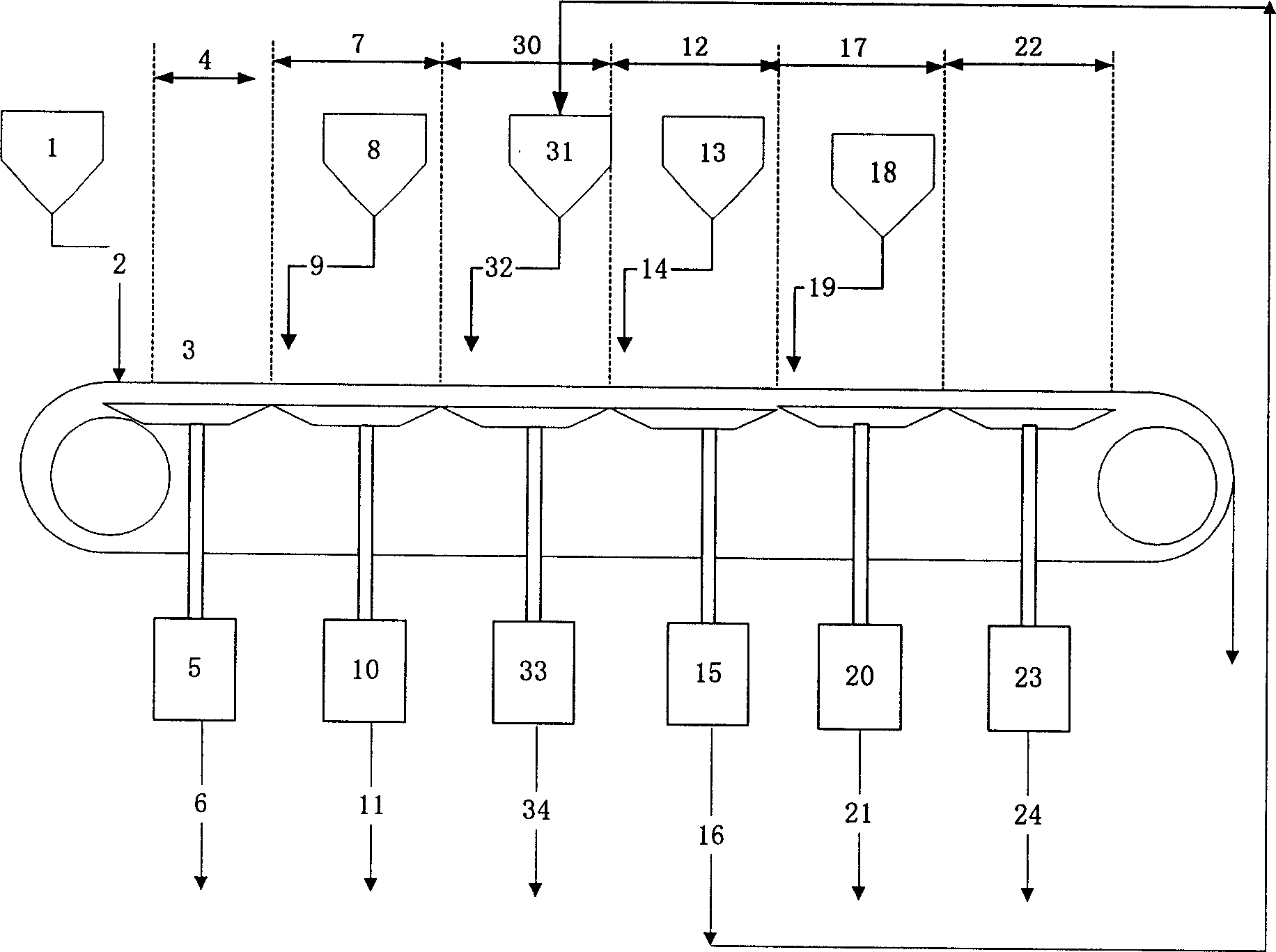

Method used

Image

Examples

example 1

[0144] The present example illustrates the method provided by the invention with a Buchner funnel as a separation device simulating an industrial device.

[0145] 1. Formation of filter cake.

[0146] Mix and beat NaY zeolite (the specifications are the same as in Comparative Example 1) and deionized water to prepare a slurry with a pH value of 8 and a solid content of 100 g / L. The resulting slurry is heated to 70°C under stirring and poured into a Buchner funnel , At the same time, vacuumize the filter flask of the Buchner funnel to 0.05 MPa. Under vacuum, a layer of filter cake about 1 cm thick is formed on the filter cloth of the Buchner funnel, and the waste liquid in the suction filter bottle is emptied. The filter cloth used is the same as that of Comparative Example 1.

[0147] Second, pH adjustment.

[0148] Keep the vacuum in the filter bottle. When there is no liquid on the surface of the filter cake, immediately and slowly add an aqueous solution of hydrochloric ...

example 2

[0158] The present example illustrates the method provided by the invention with a Buchner funnel as a separation device simulating an industrial device.

[0159] Use the same piece of filter cloth that example 1 uses, repeat above-mentioned whole operation process, when repeating the 30th time, the color of filter cloth still does not change, and filtering speed is still identical with the first time.

example 3-6

[0161] The following examples illustrate the method provided by the invention with the Buchner funnel as the separation device simulation industrial device.

[0162] Carry out rare earth ion exchange to NaY molecular sieve by the method of example 1, difference is, (1) the temperature of molecular sieve slurry is different, (2) used hydrochloric acid solution is replaced with other acid or ammonium salt solution when adjusting pH value, makes inflow filter bottle The waste liquid drops to different pH values; (3) The type, concentration, temperature and / or amount of the solution used for ion exchange are different. The temperature of the slurry containing molecular sieves, the acid or ammonium salt used when adjusting the pH value, the pH value that the waste liquid flowing in the filter bottle is reduced to, the type, temperature and / or consumption of the solution used for ion exchange are listed in Table 1 respectively. The rare earth oxide and sodium oxide contents in the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com