Flatness detecting method and detecting instrument thereby

A flatness detection and detection device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems that cannot be realized, the lines cannot be dense, the electric connector and the circuit board telecommunication connection line are interrupted, etc., to overcome the judgment wrong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

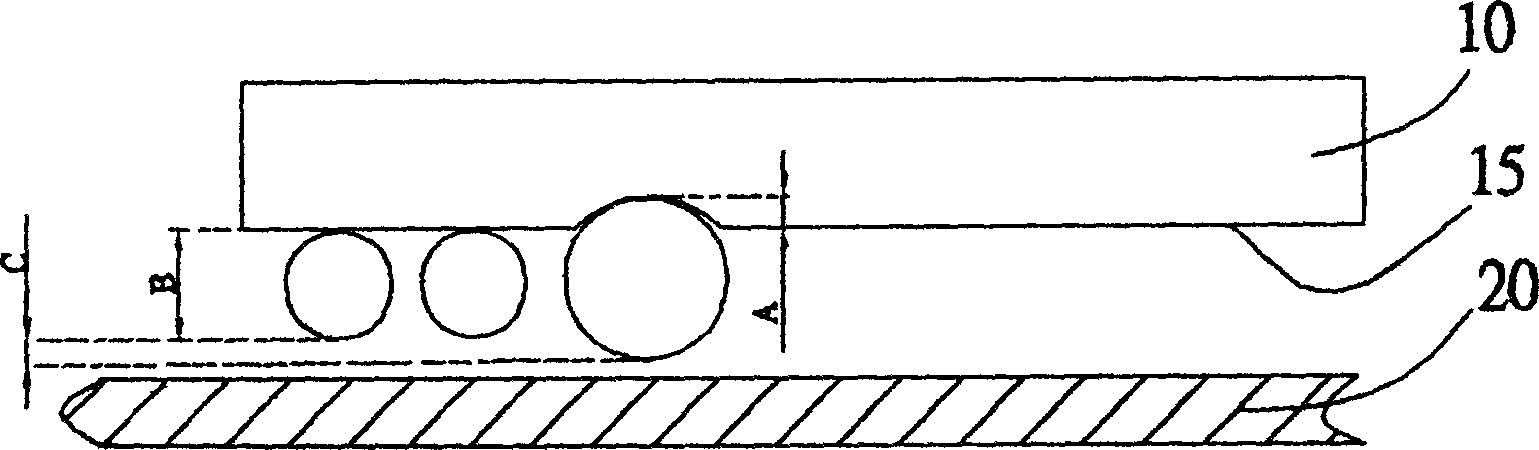

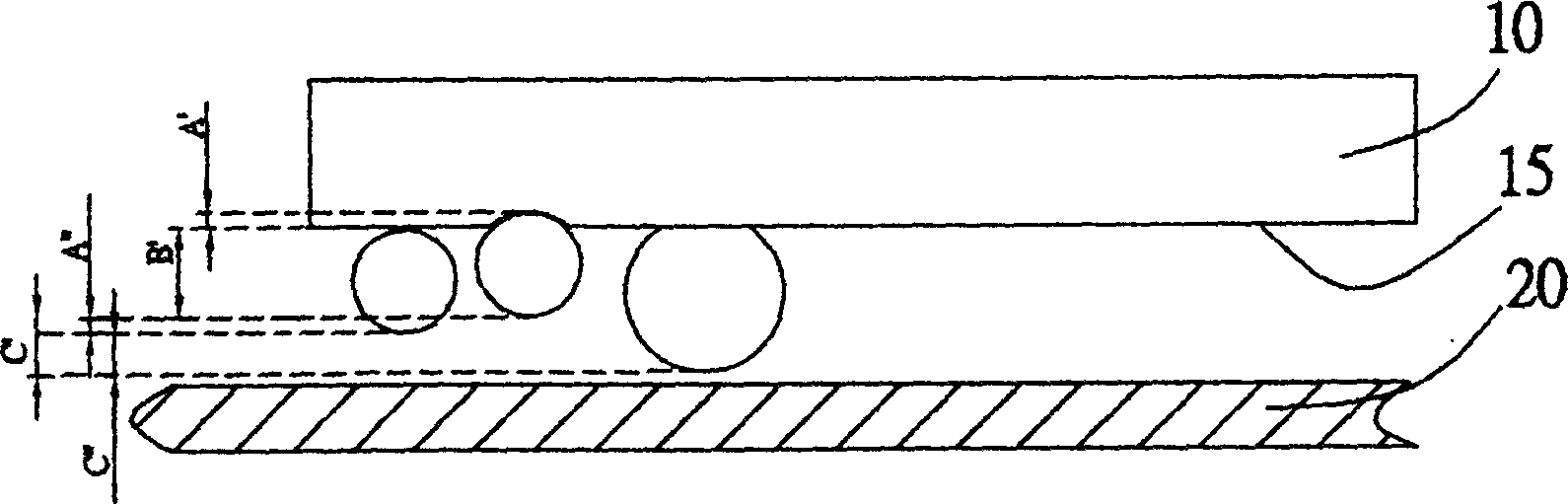

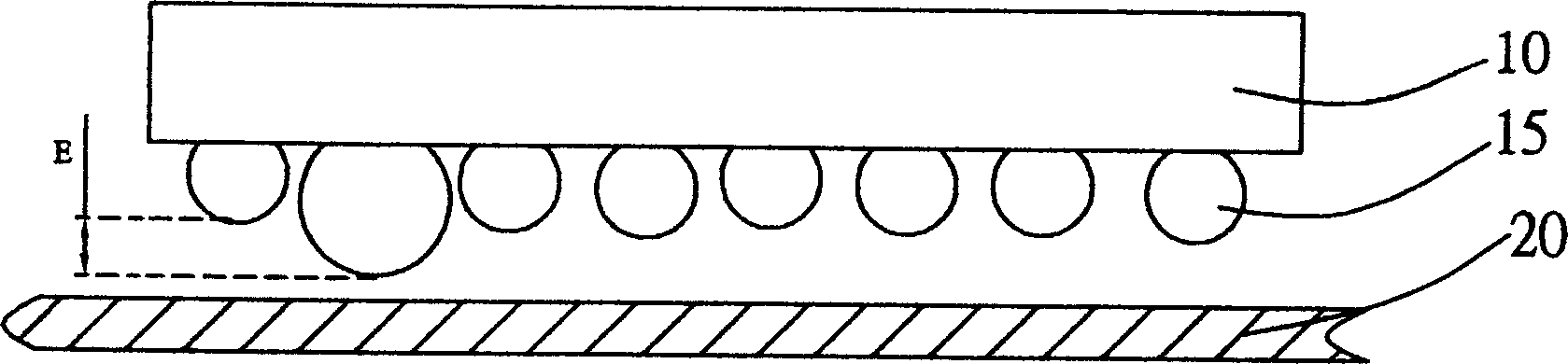

[0014] see Figure 5 As shown, implementing the flatness detection method of the present invention includes the following steps: 1) providing a transparent base, and placing the electronic component on the transparent base, wherein the side where the electronic component is provided with a soldering portion is connected to the transparent base Relatively arranged, in this embodiment, the above-mentioned electronic component is an electrical connector 40, and the electrical connector 40 is provided with a conductive terminal (not shown), and a solder ball 41 is provided at the end of the conductive terminal so that the electrical connector 40 adopts a BGA (Ball grid array) is connected to the circuit board (not shown), the welding part is the solder ball 41, and the above-mentioned transparent base is a glass substrate 42 with a high level; The distance H between the bottom surface of the solder ball 41 of the connector 40 and the surface of the glass substrate 42, in this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com