Method of turbine operation

An operation method and turbine technology, which is applied to steam engine devices, engine components, machines/engines, etc., can solve problems such as fuel quality fluctuations, turbine damage, and impact on operation, and achieve the effect of avoiding the danger of false start protection functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

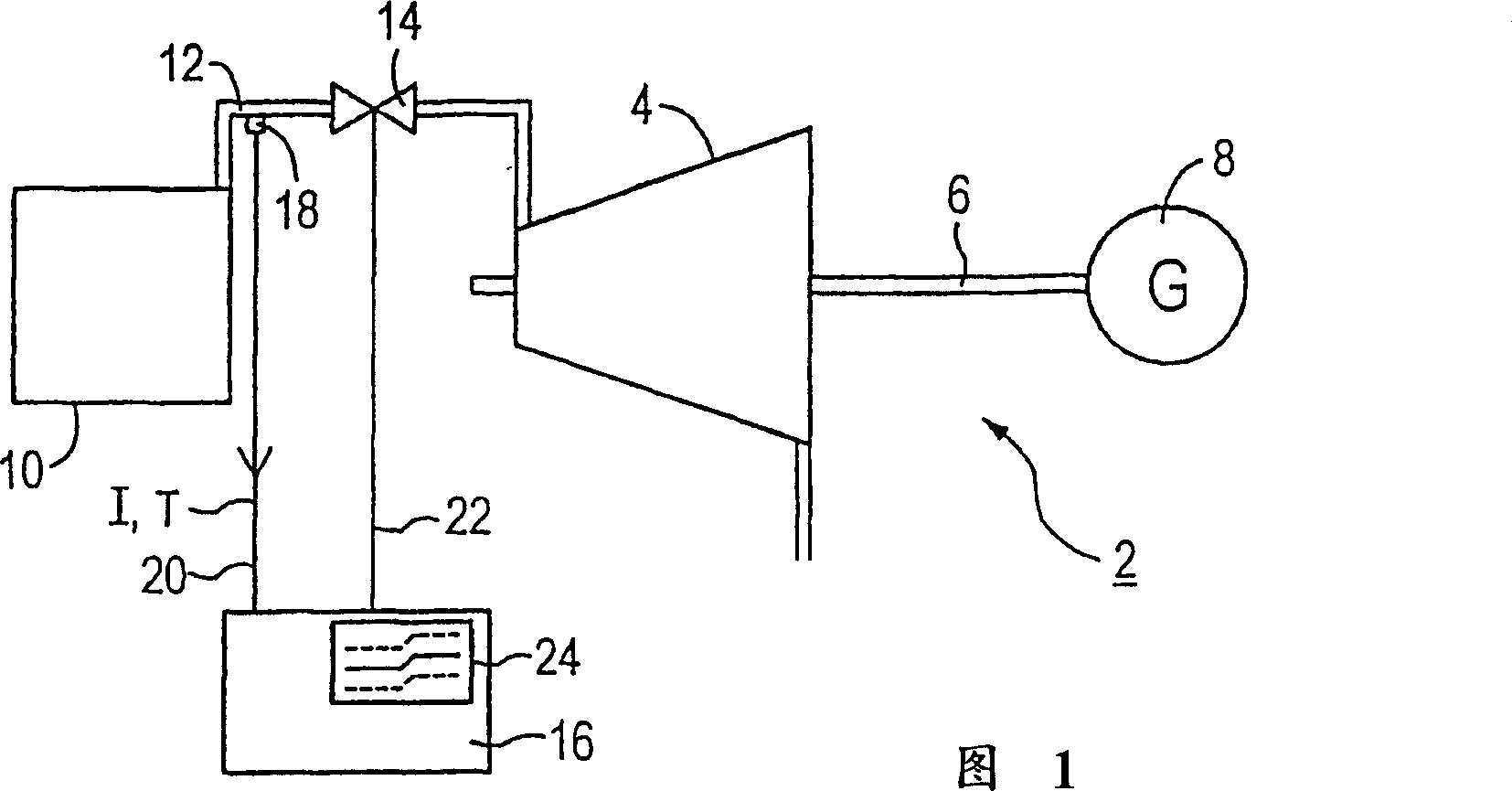

[0029] The turbine arrangement 2 according to FIG. 1 includes a turbine 4 , in particular a steam turbine, which is connected via a shaft 6 to a generator 8 for generating electrical energy. Turbine 4 is driven by gaseous medium, especially live steam. Live steam is generated in the boiler 10 and fed from there via a steam line 12 to the turbine 4 . The steam line 12 can be blocked by means of a valve 14, in particular a quick closing valve. The turbine unit 2 also includes a protective device 16 and a temperature sensor 18 which, in the exemplary embodiment according to FIG. 1 , is mounted directly on the steam line 12 in the region of the boiler 10 . The protection device 16 is connected to the temperature sensor 18 via a data line 20 and to the valve 14 via a control line 22 . Turbine protection is activated by triggering a snap shut down via control line 22 if required.

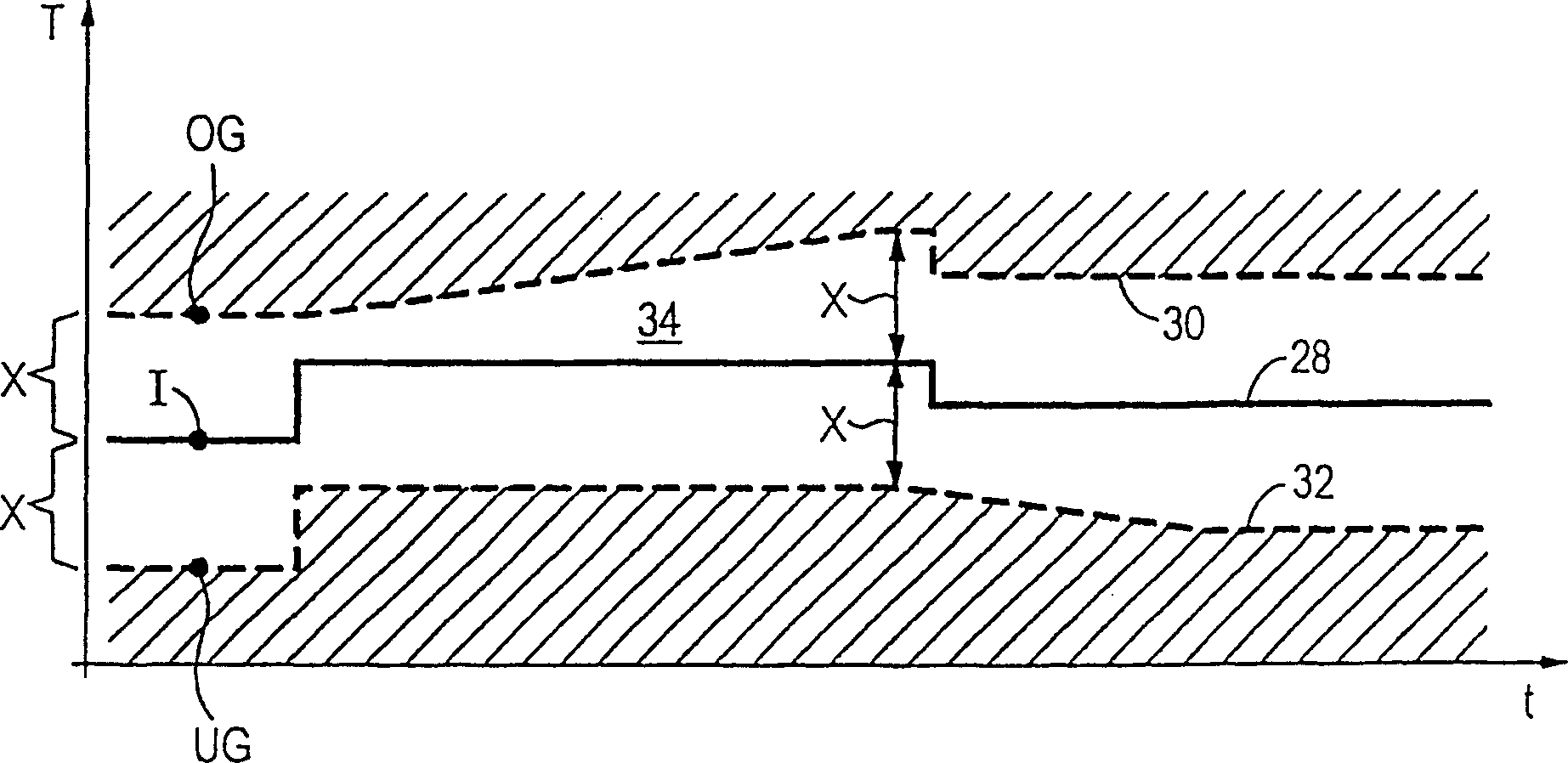

[0030] The temperature sensor 18 is used to detect the actual value I of the temperature T of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com