Straight line motor

A technology of linear motors and armatures, applied to electrical components, electromechanical devices, electric components, etc., can solve problems such as stator space loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

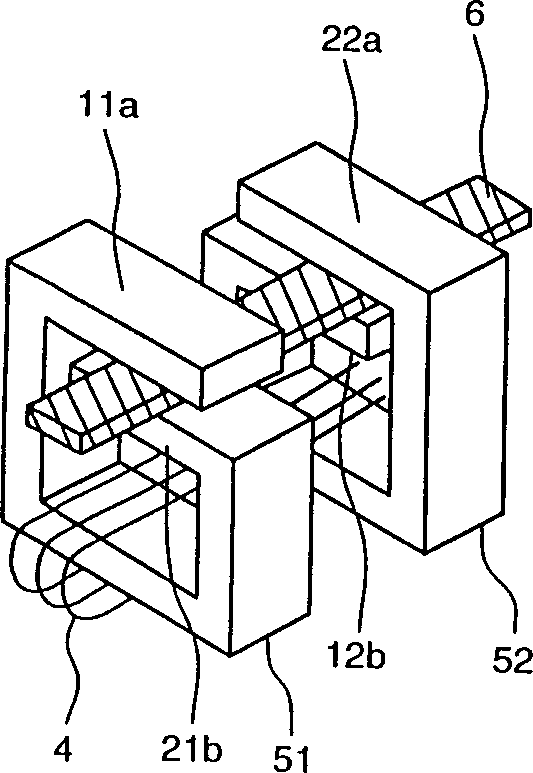

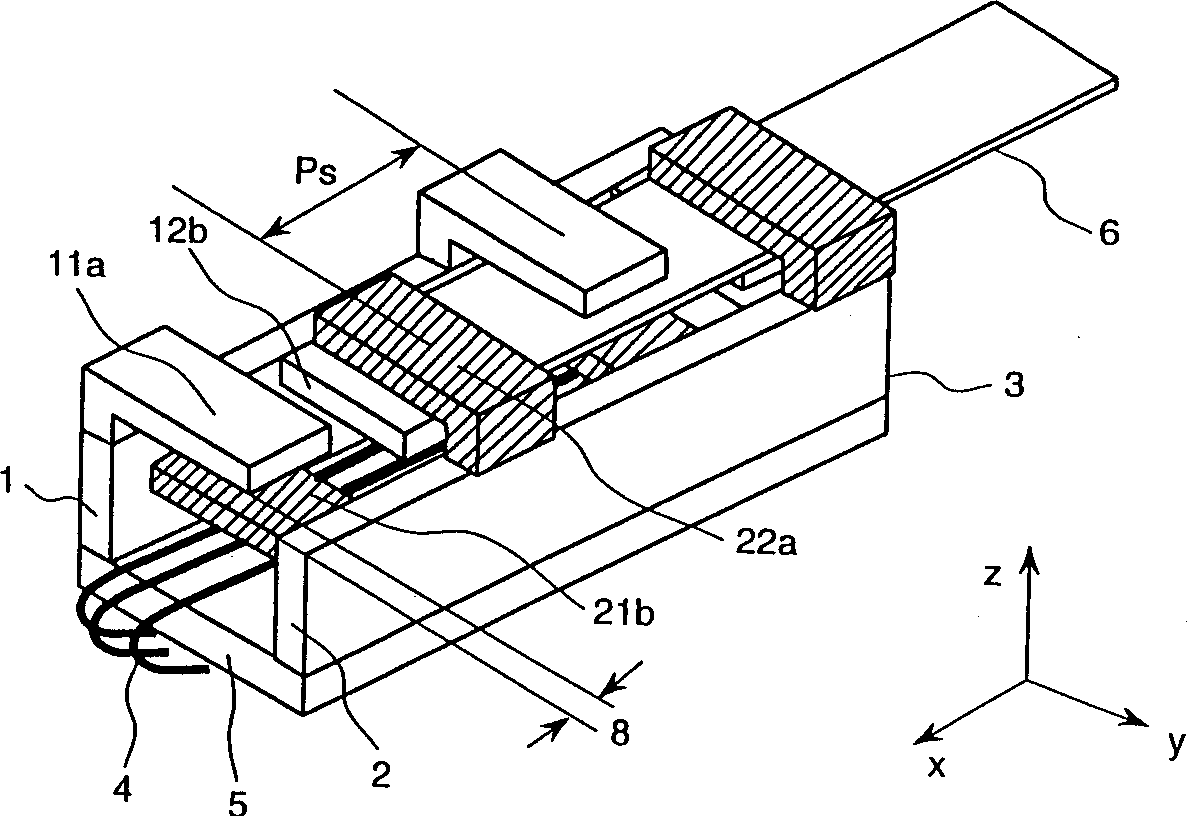

[0026] Referring to Figure 1A to Figure 14 Preferred modes of the linear motor of the present invention will be described. In the different figures, the same reference numerals are used to designate the same and equivalent parts, components or entities.

[0027] FIG. 1A illustrates the basic structure of an embodiment of the linear motor of the present invention, and FIG. 1B illustrates a multi-pole toothed linear motor expanded from the basic structure of the embodiment shown in FIG. 1A.

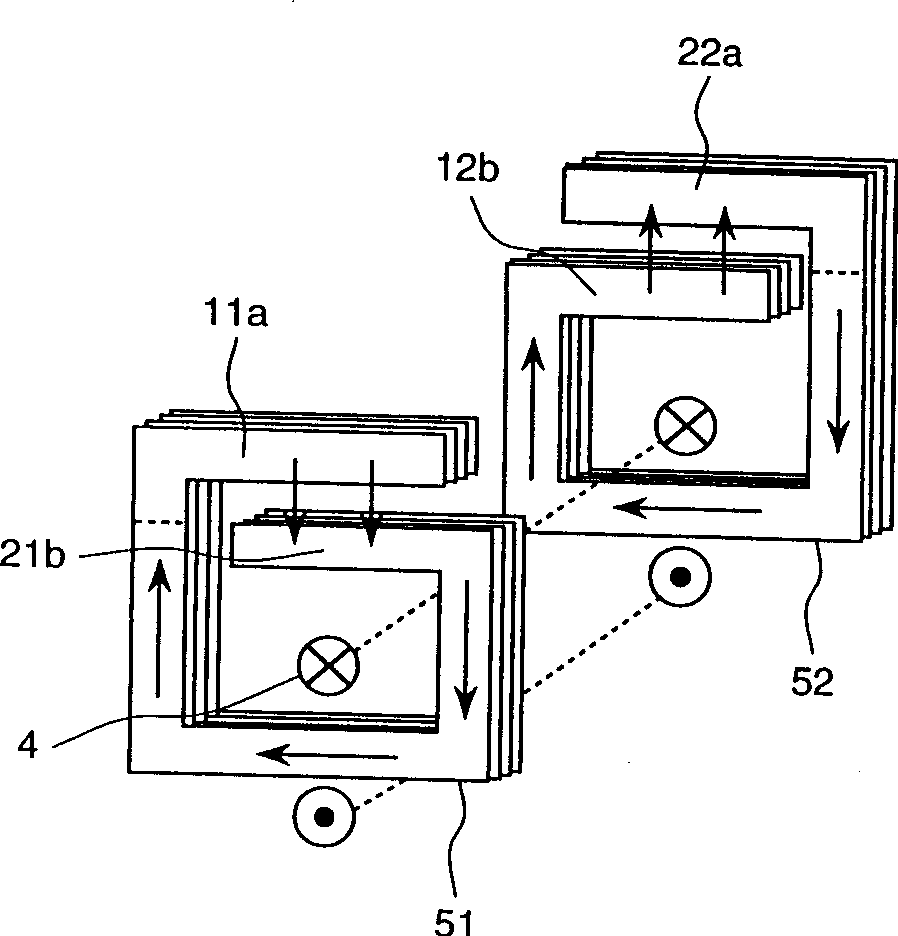

[0028] As shown in Fig. 1A, numeral 51 designates a core with a first opposing portion, and numeral 52 designates a core with a second opposing portion. The cores 51 and 52 are constructed such that the upper and lower magnetic poles of one of the cores 51 and 52 are opposite in polarity to the upper and lower magnetic poles of the other of the cores 51 and 52 .

[0029] The first opposing portion includes the upper magnetic pole teeth 11 a and the lower magnetic pole teeth 21 b of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com