Deflecting coil

A technology for installing deflection coils and coils, applied in the direction of electrode devices and related components, cathode ray tubes/electron beam tubes, discharge tubes, etc., can solve the problems of no deflection deformation, simple action of electron beams, and no description, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiment of the invention

[0043] Embodiments of the present invention will be described below with reference to the drawings.

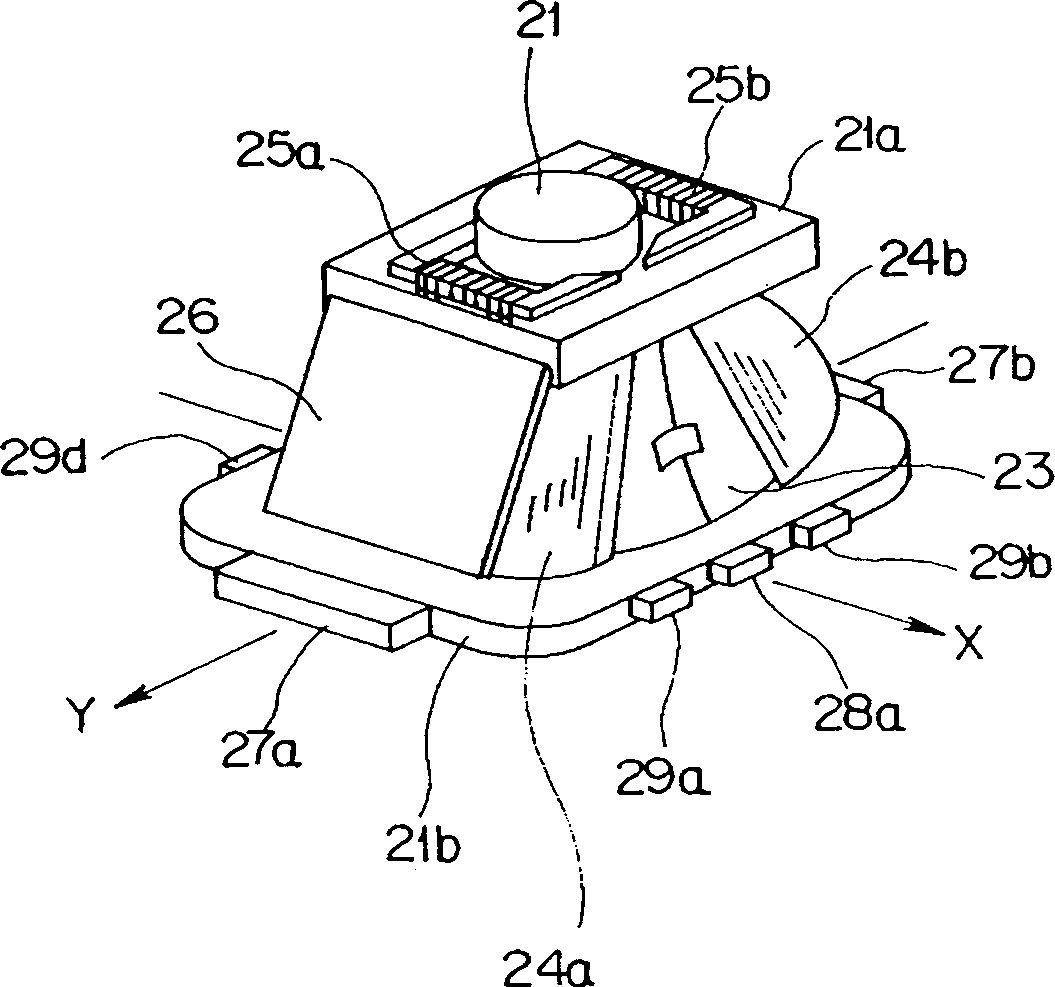

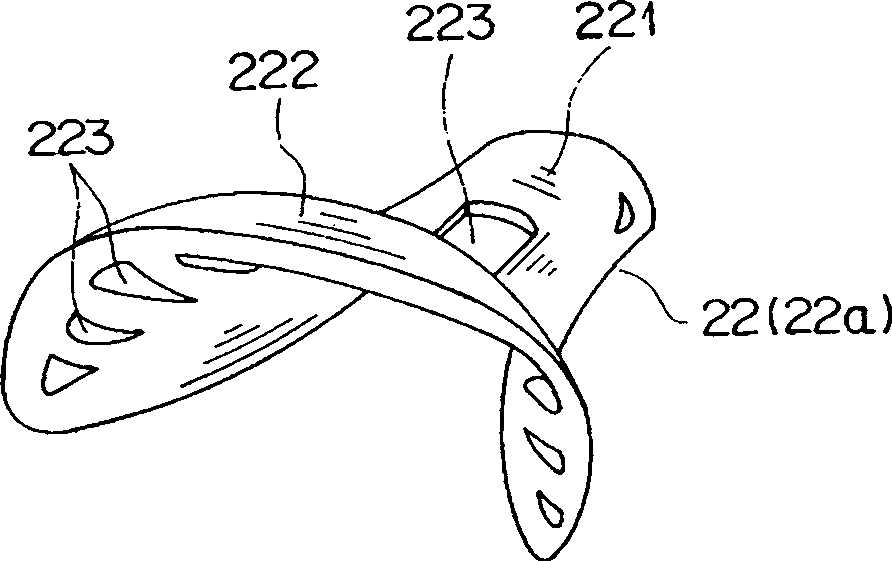

[0044] figure 1 It is a perspective view of a deflection yoke device according to an embodiment of the present invention. In the case of this embodiment, the cone shape of the CRT on which the deflection yoke device is installed is square, so that the saddle-shaped horizontal deflection coil installed on the deflection yoke device is also as figure 2 Shown square.

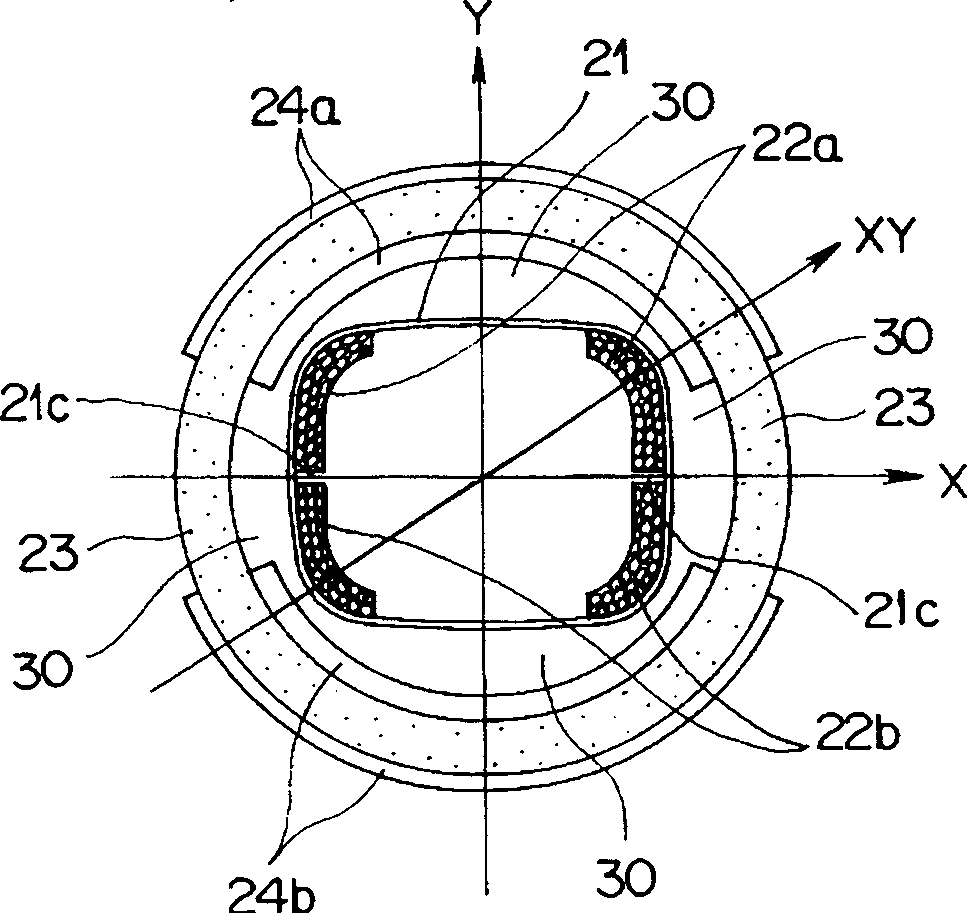

[0045] The coil spacer 21 made of an insulator has a square shape that gradually expands from the small-diameter portion on the neck side to the large-diameter portion on the front side, and a pair of horizontal deflection coils 22 ( figure 2 Only shows the coil 22a) of the half body in a pair of coils 22a, 22b, on the outer side is provided with a pair of horn-shaped vertical deflection coils 24 (24a, 24b) wound directly on the circular magnetic core 23 .

[0046] In ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com