Sewing machine

A sewing machine and machine frame technology, applied in the field of sewing machines, can solve problems such as the complexity of the sewing machine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

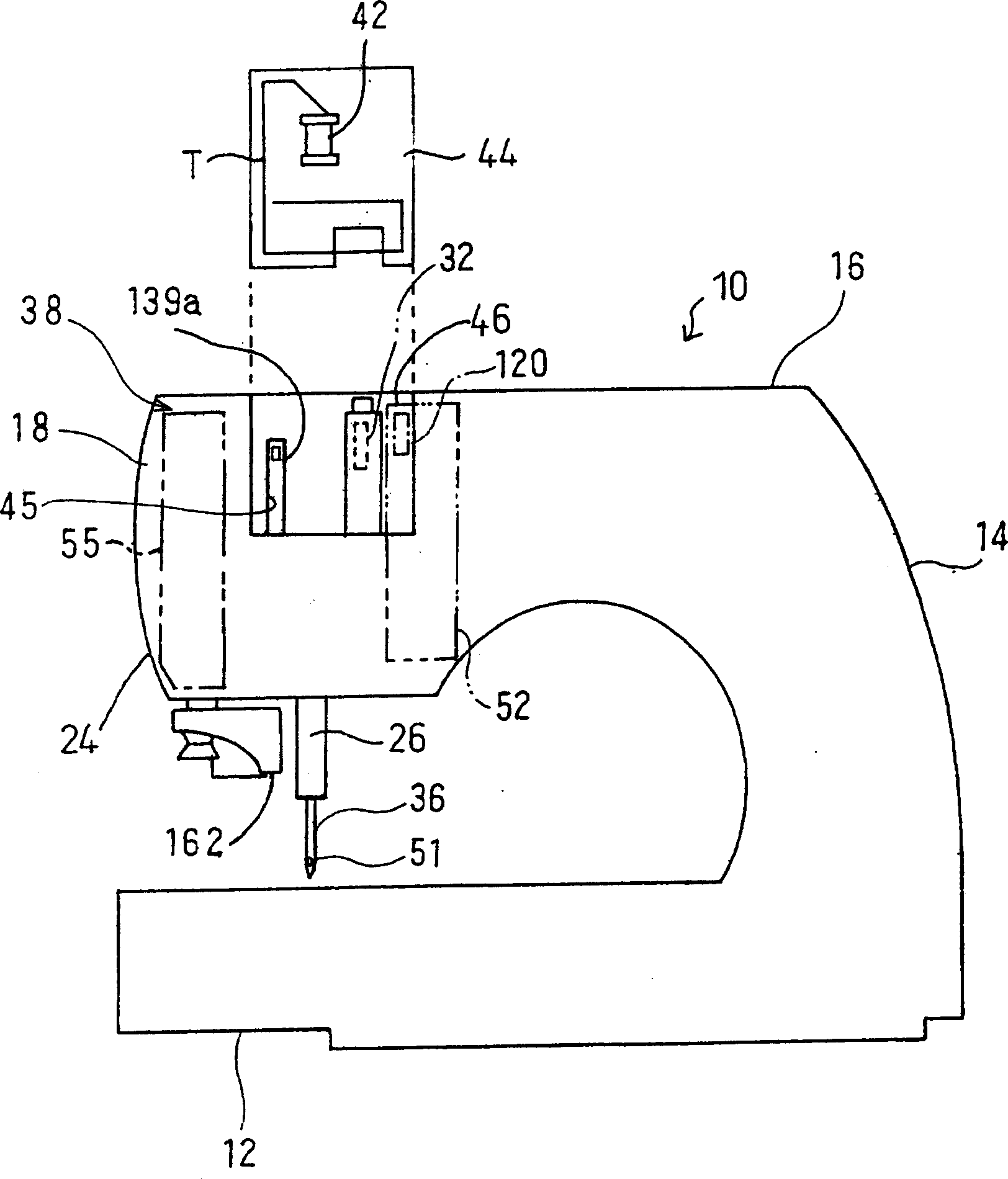

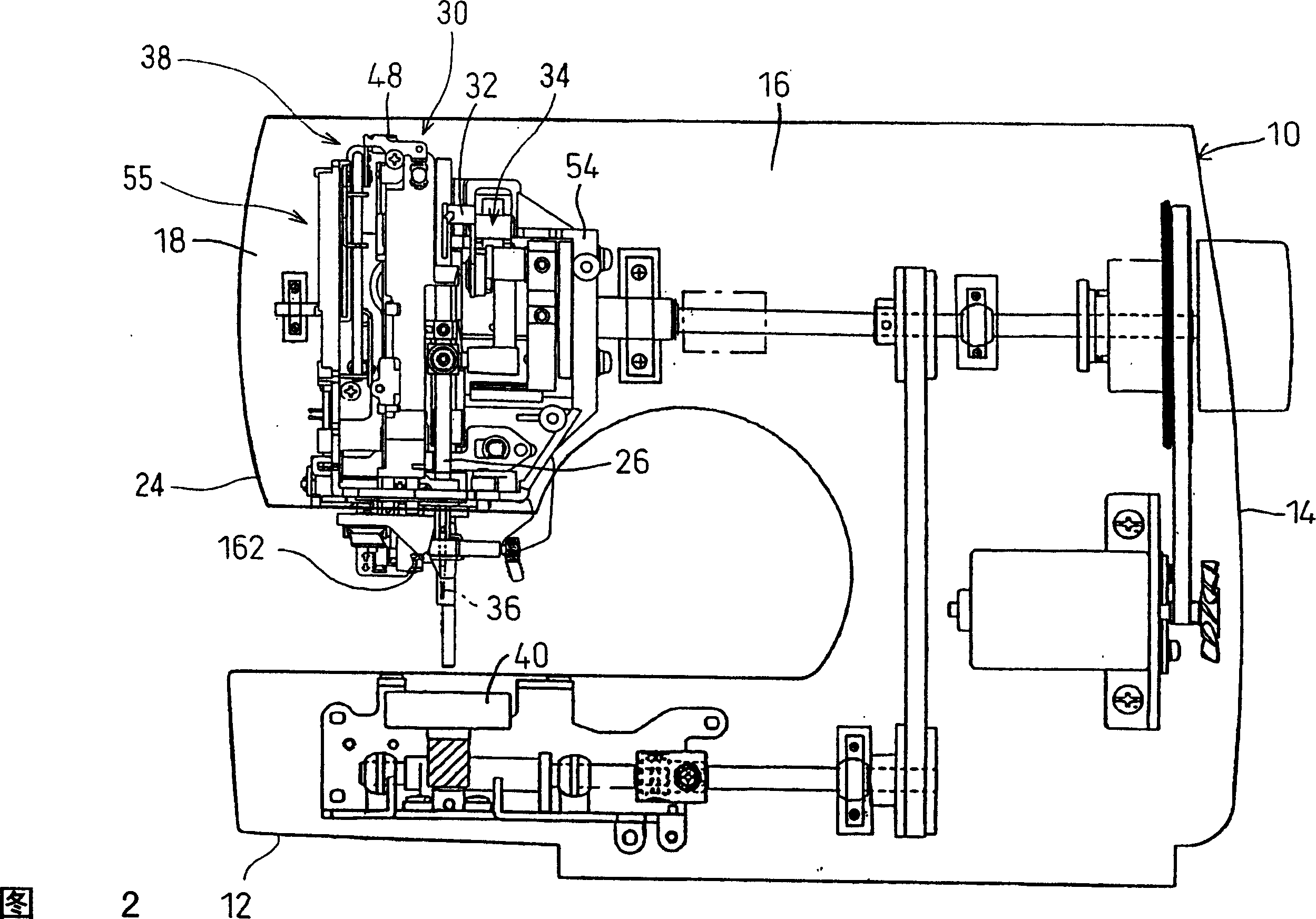

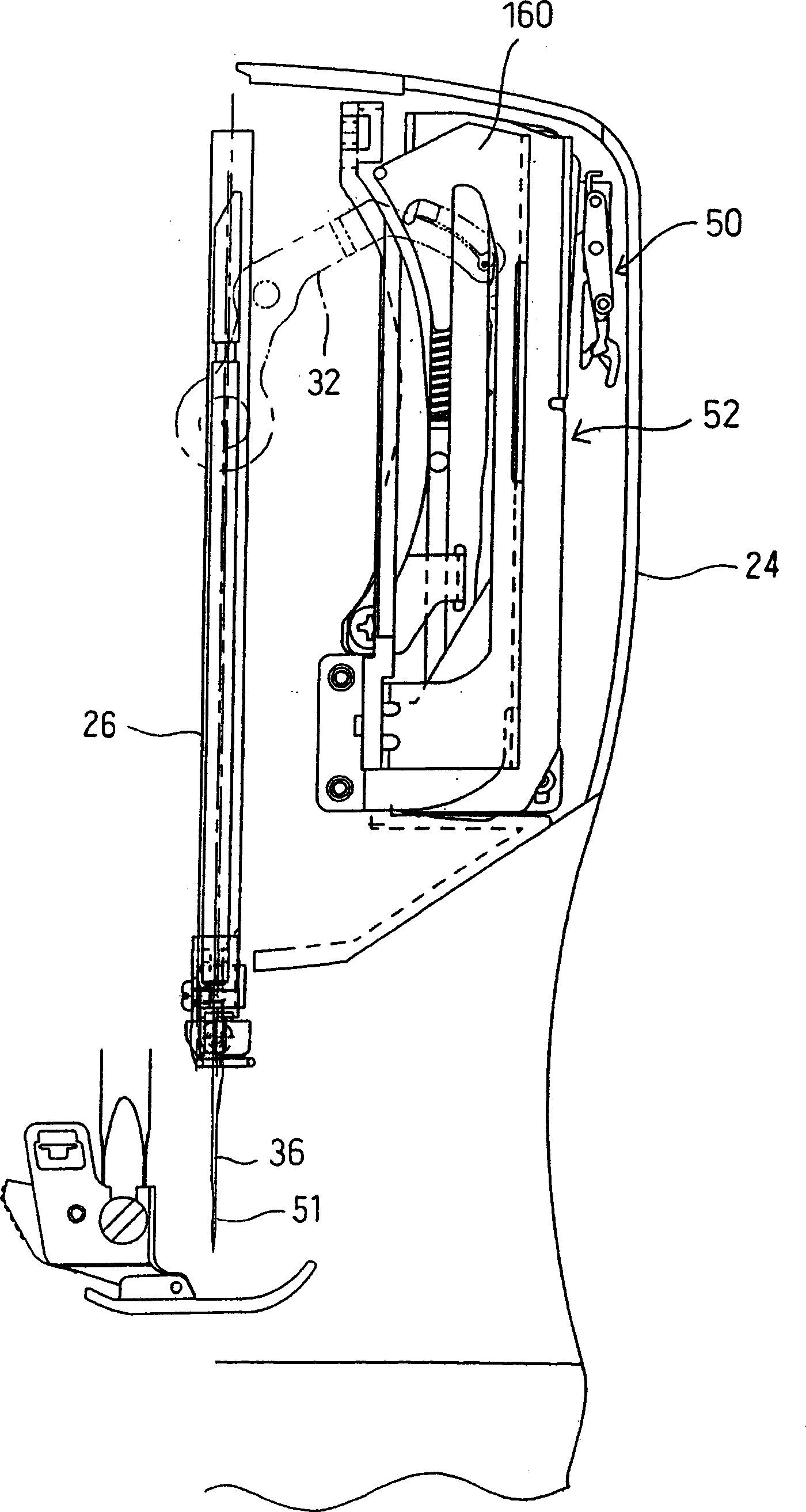

[0031] Hereinafter, an embodiment of the present invention will be described with reference to the accompanying drawings. refer to figure 1 and Fig. 2, which schematically shows a sewing machine 10 to which the threading device of the present invention is applied. Sewing machine 10 comprises: a sewing bed portion 12, this sewing bed portion 12 has a horizontal plane; A support 14, this support 14 stands upright from the right end of bed portion 12; the upper end extends to the right; and a machine head 18 located at the left end of the arm 16 . A needle shank 26 extends downwardly from the head 18 . A sewing needle 36 is detachably connected to the lower end of the needle bar 26 . The head 18 has enclosed a needle bar driving mechanism 28 for moving the needle bar up and down, a needle bar swinging mechanism 30 for making the needle bar 26 horizontally swing, and a needle bar swinging mechanism 30 for making the needle bar drive mechanism 28 horizontally swing. A needle th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com