Auxiliary mechanism and method of forcing submarine to dive or lift fast

An auxiliary mechanism and submarine technology, applied to underwater ships, underwater operating equipment, ships, etc., can solve the problem of fatal blows from the enemy, unsatisfactory speed of diving or rising, and limited speed of filling or draining And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

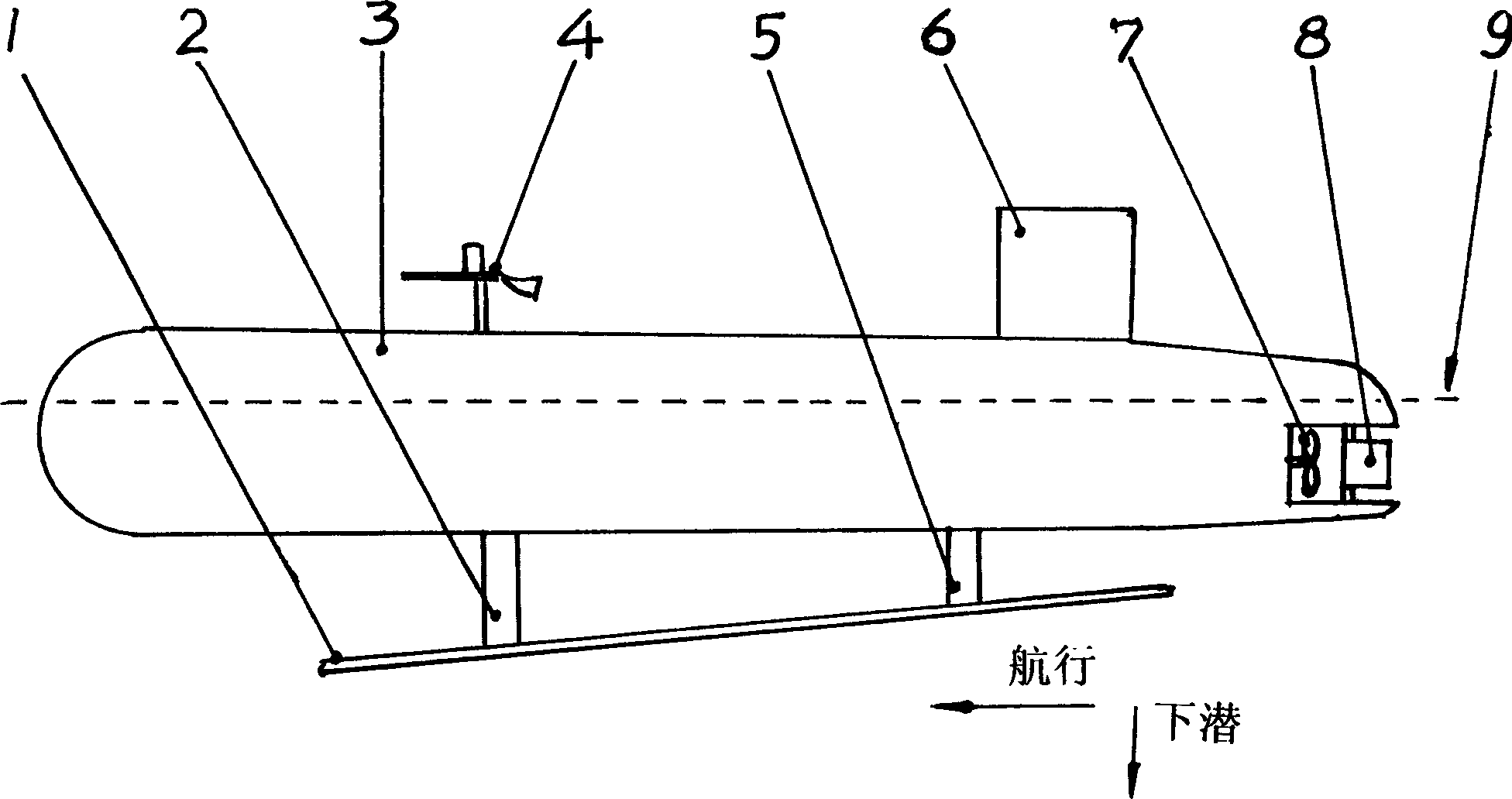

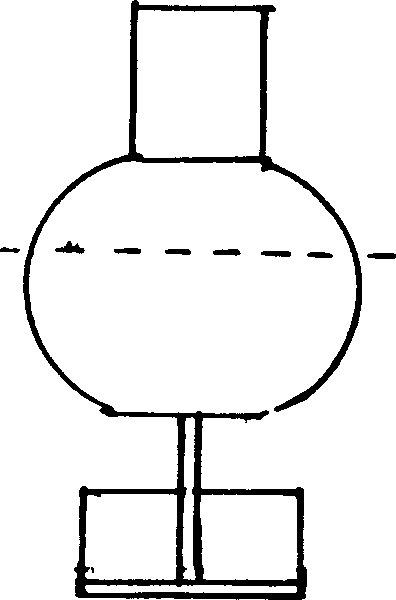

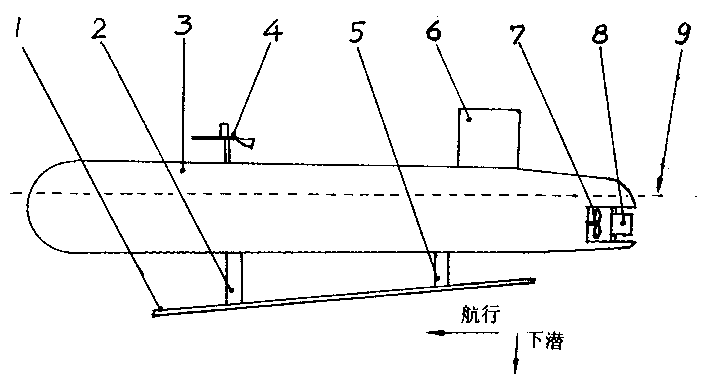

[0018] The cutting hydrofoil (1) is positioned under the bottom of the submarine (3), and the cutting hydrofoil (1) is positioned by the front support rod (2) and the rear support rod (5). When the submarine (3) advances, the length of the front support rod (2) and the rear support rod (5) stretching out from the bottom of the submarine (3) to enter the water body is used to adjust the inclination angle of the cutting hydrofoil plate (1) and the horizontal plane to realize The degree of vertical acceleration of the submarine (3) when diving or ascending.

[0019] In a state of emergency, if the submarine (3) sailing on the water surface has no time to complete the water filling process and make it dive by conventional means in a short time, in order not to miss the fighter plane or suffer a fatal blow from the enemy, Fully at the fastest speed: adjust the downward forward angle of the cutting hydrofoil (1), and then leave the original position with full power, and simultaneous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com