Bullet lock having bullet groups with different elastic forces

A pin group and pin lock technology, which is applied in the field of pin locks, can solve problems such as non-prevention of technical opening, inability to control the sliding level of magnetic pins, and restrictions on the amount of pin sets, and achieve reliable anti-theft performance, low manufacturing cost, and a large number of keys. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

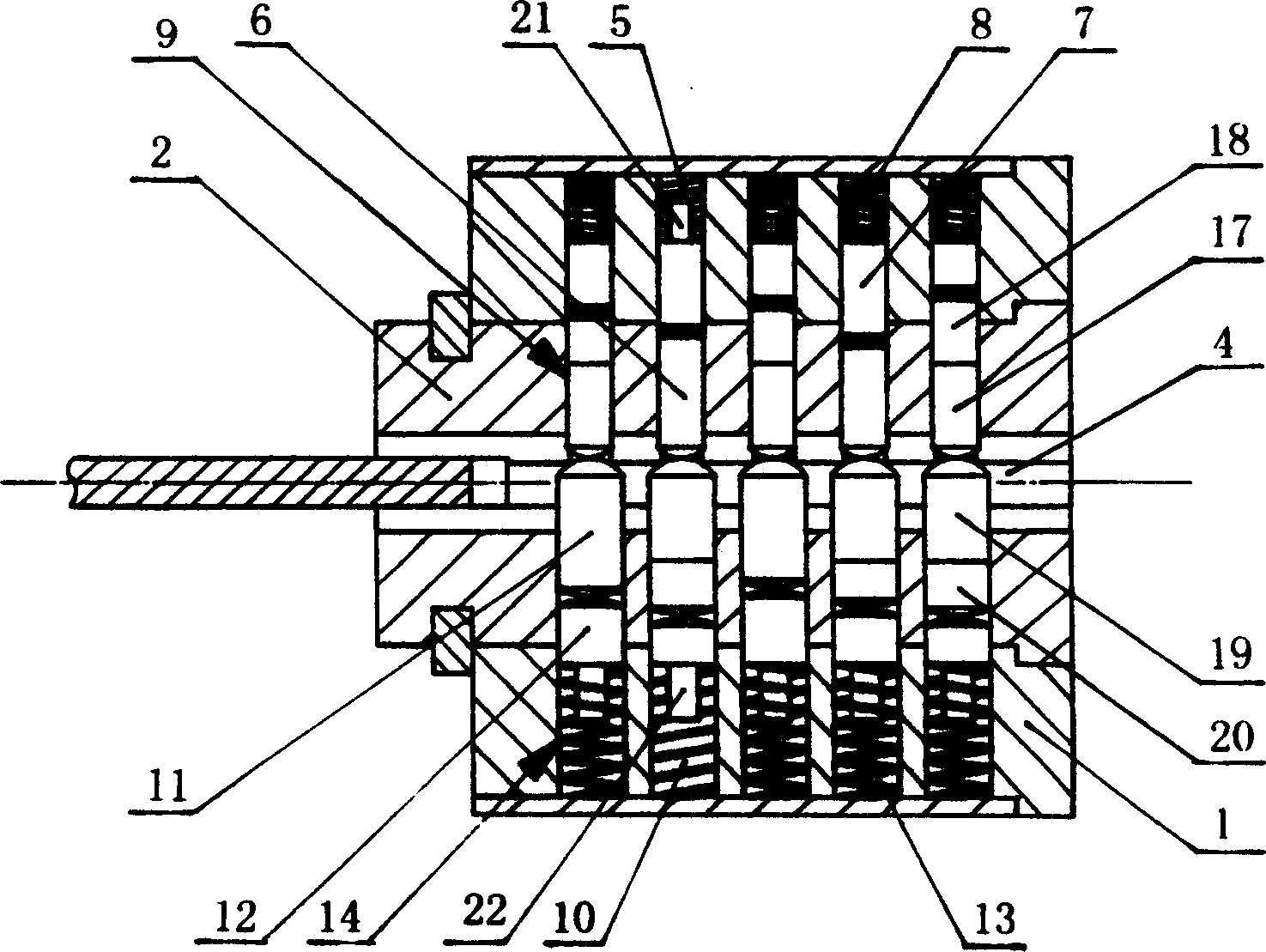

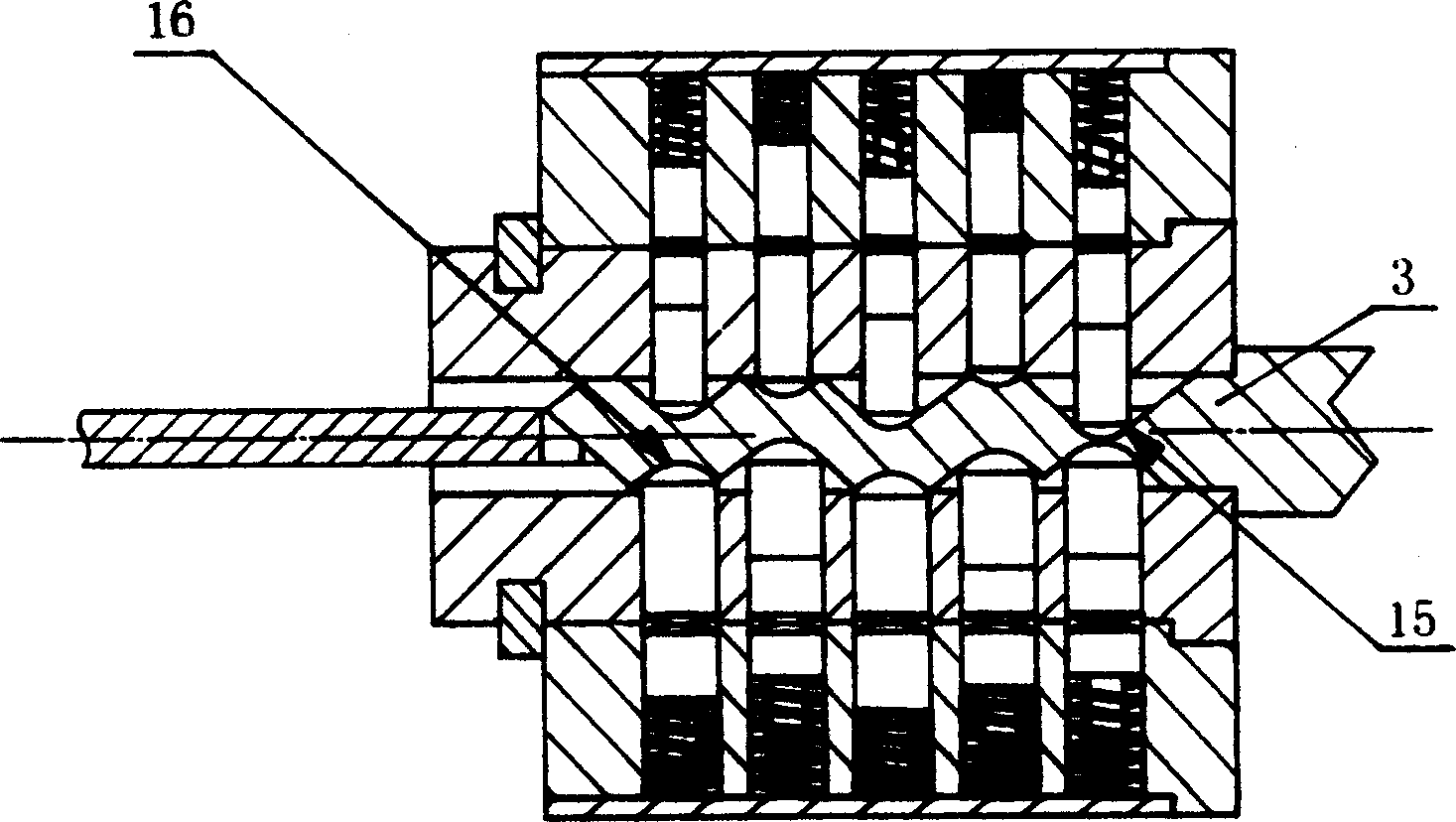

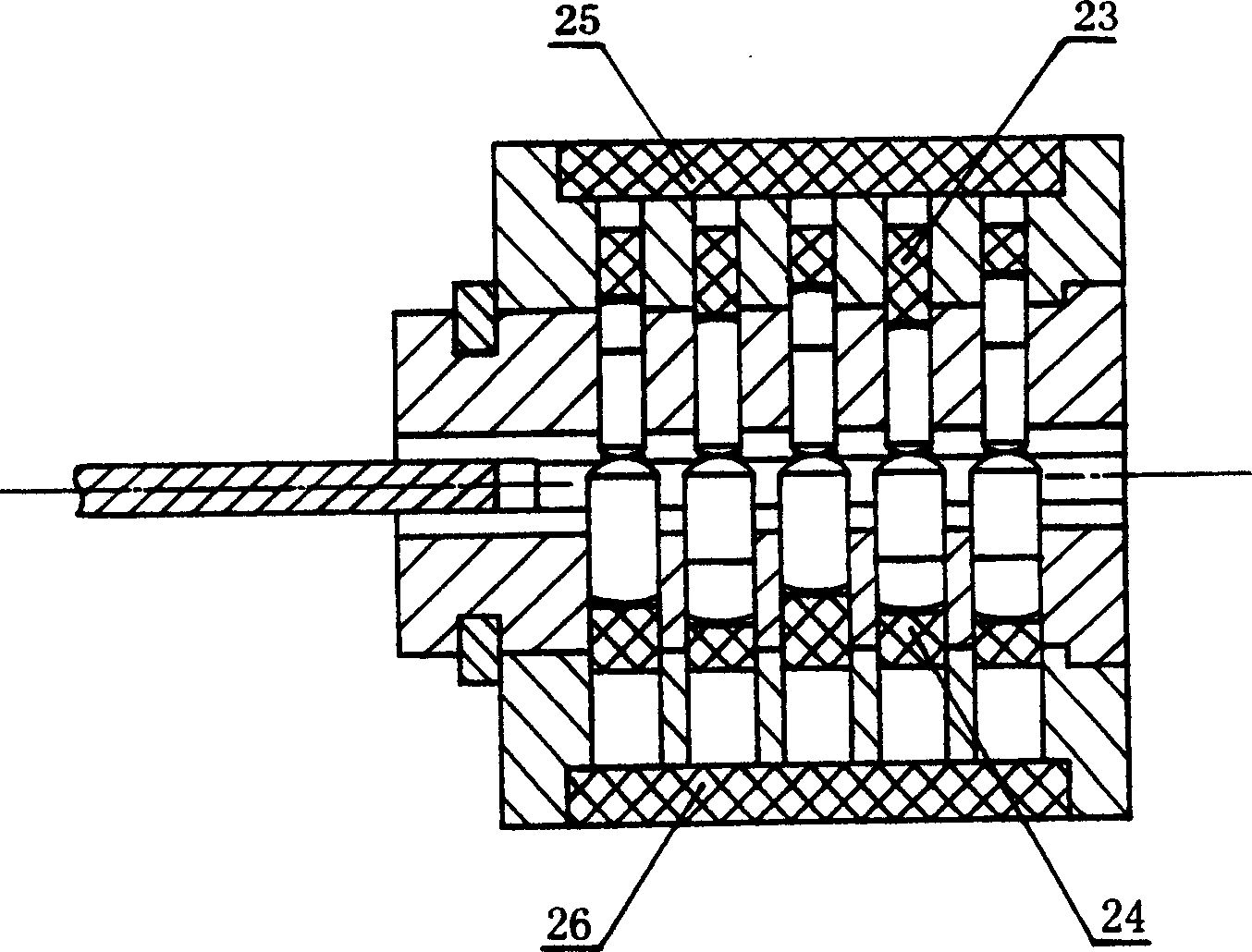

[0018] A tumbler lock with groups of tumblers of unequal elastic force, comprising a lock cylinder body 1 , a lock cylinder 2 and a key 3 . exist figure 1 , 2In the described embodiment, a row of relatively thin pinholes 5 is provided on one side of the lock core body 1 through the lock core body 1 and the lock core 2 to the keyhole 4, and a corresponding number of relatively thin pin holes 5 are inserted. A relatively thin pin group 9 composed of an upper pin 6, a relatively thin lower pin 7 and a relatively weak compression spring 8; on the other side corresponding to the lock core body 1, a penetrating lock core body 1 and a lock core 2 are provided. A row of relatively thick pinholes 10 to the keyhole 4 is inserted into a corresponding number of relatively thick pinholes composed of relatively thick upper pins 11, relatively thick lower pins 12 and relatively strong compression springs 13. Set of 14 marbles. When the key 3 is not inserted, a row of relatively thick pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com