Condenser pressure-retaining energy-saving type refrigeration system for refrigerator

A refrigeration system and condenser technology, applied in the field of refrigerator refrigeration systems, can solve the problems of start-up and shutdown losses, and achieve the effects of reducing shutdown losses, simple structure, and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

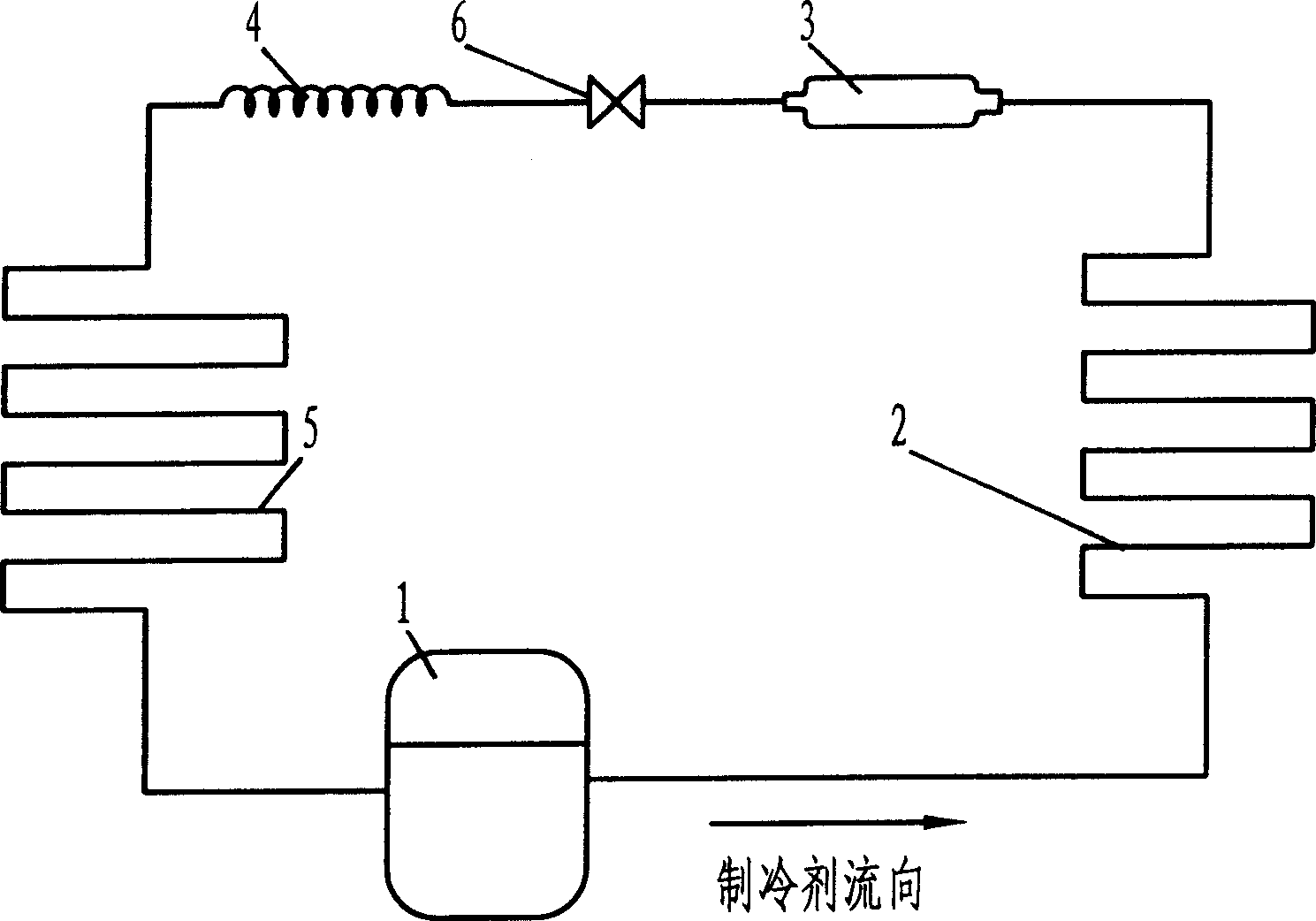

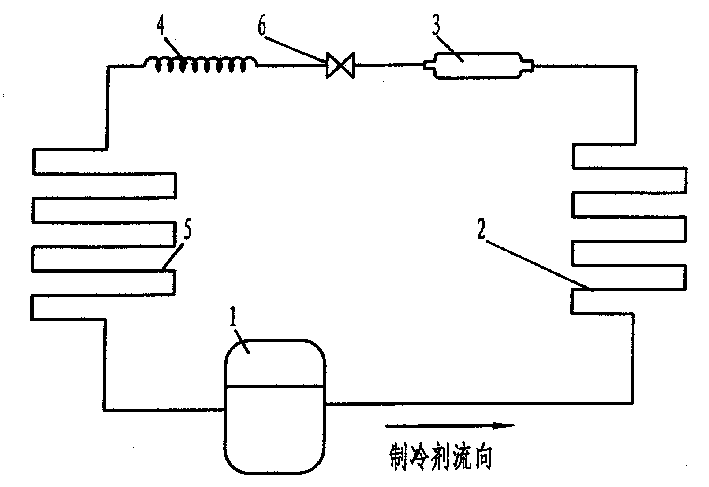

[0011] see figure 1 , the present embodiment consists of a compressor 1, a condenser 2, a filter 3, a capillary tube 4 and an evaporator 5 to form a refrigerant circulation system, and on the pipeline from the condenser 2 to the capillary tube 4, a flow regulating mechanism 6 is set. The mechanism 6 is started and closed synchronously with the start and stop of the compressor 1, and is used to prevent the refrigerant in the high-pressure side condenser 2 from flowing to the low-pressure side where the evaporator 5 is located when the compressor 1 is stopped. The flow regulating mechanism 6 may be a solenoid valve or the like.

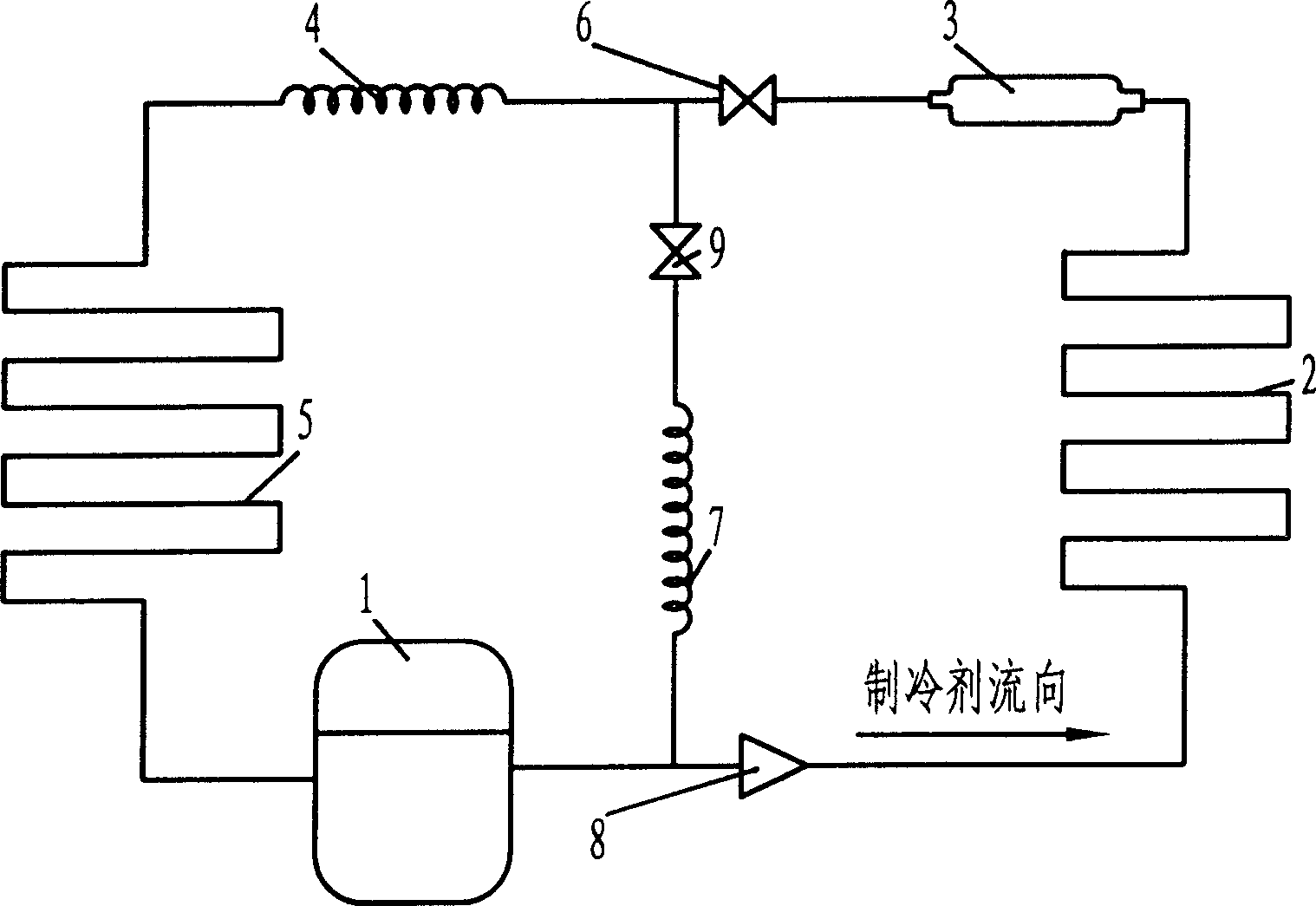

[0012] In the case of maintaining the pressure on the condenser 2, in order to ensure that the compressor 1 can be started normally, a pressure relief branch can be set for the compressor 1 so as to balance the pressure at the discharge port and the suction port of the compressor. The specific way is as figure 2 As shown, the pressure relief capillar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com