Microscope for operation

A technology for microscopes and surgery, which is applied in the field of surgical microscope devices, and can solve the problem of consuming a lot of driving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0035] [constitute]

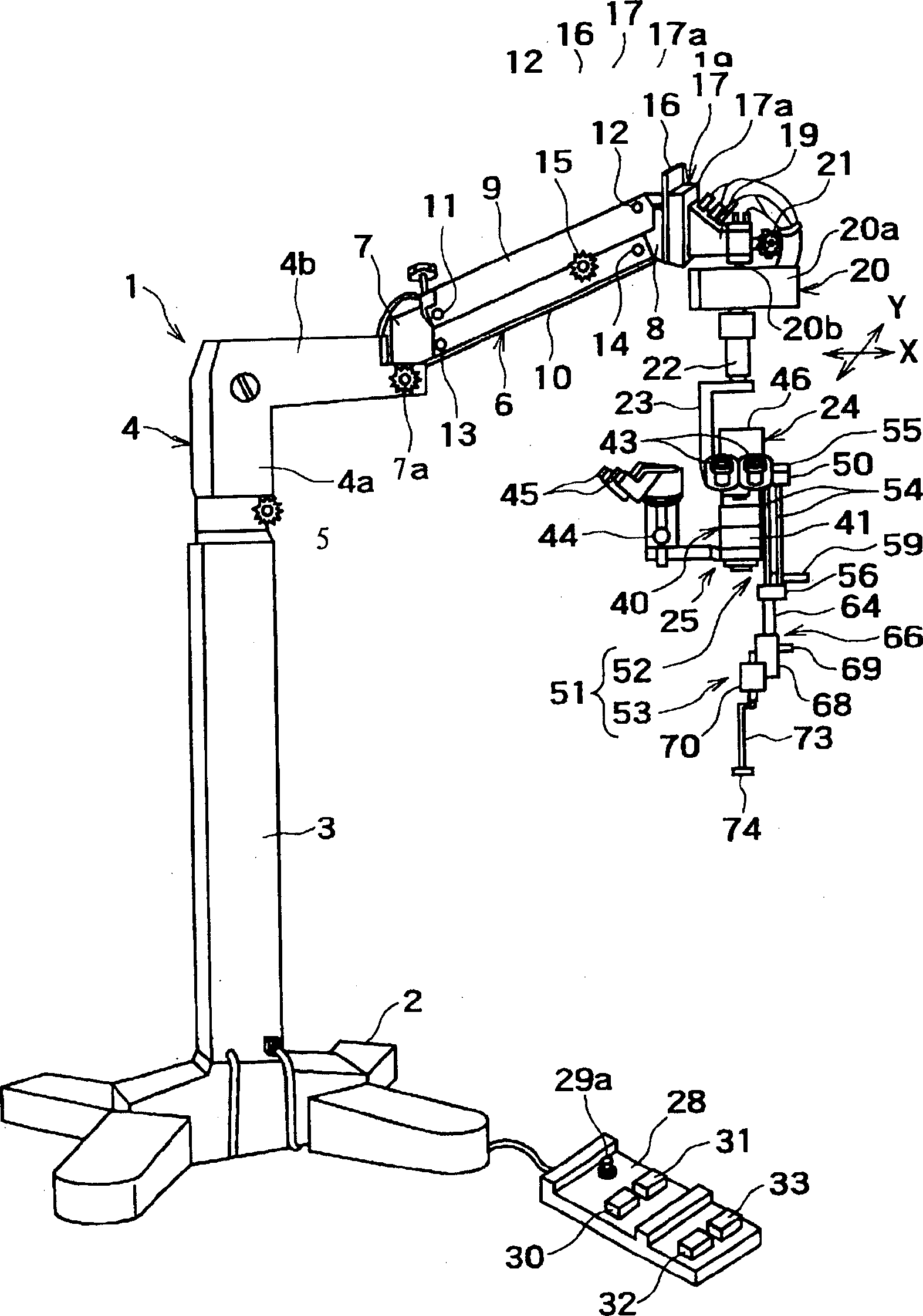

[0036] exist figure 1 Among them, 1 is a microscope device for surgery, 2 is a support base of the microscope device 1 for surgery, 3 is a pillar integrally provided with the support base 2 facing up and down, and 4 is a first arm mounted on the upper end of the pillar 3. .

[0037] The first arm 4 is formed by a support part 4a rotatably attached to the upper end of the support column 3 around a vertical rotation axis (vertical axis), and an arm part 4b provided continuously with the support part 4a horizontally. word shape. 5 is a fixing screw for fixing the supporting part 4a to the upper end part of the pillar 3.

[0038] In addition, 6 is the second arm (swing arm) of the parallel link type. The second arm 6 has a first support member 7, a second support member 8, and a pair of connecting rods 9, 10. The first support member 7 is horizontally rotatably mounted on the second arm through a rotating shaft (not shown) extending up and down. On the f...

Deformed example 1

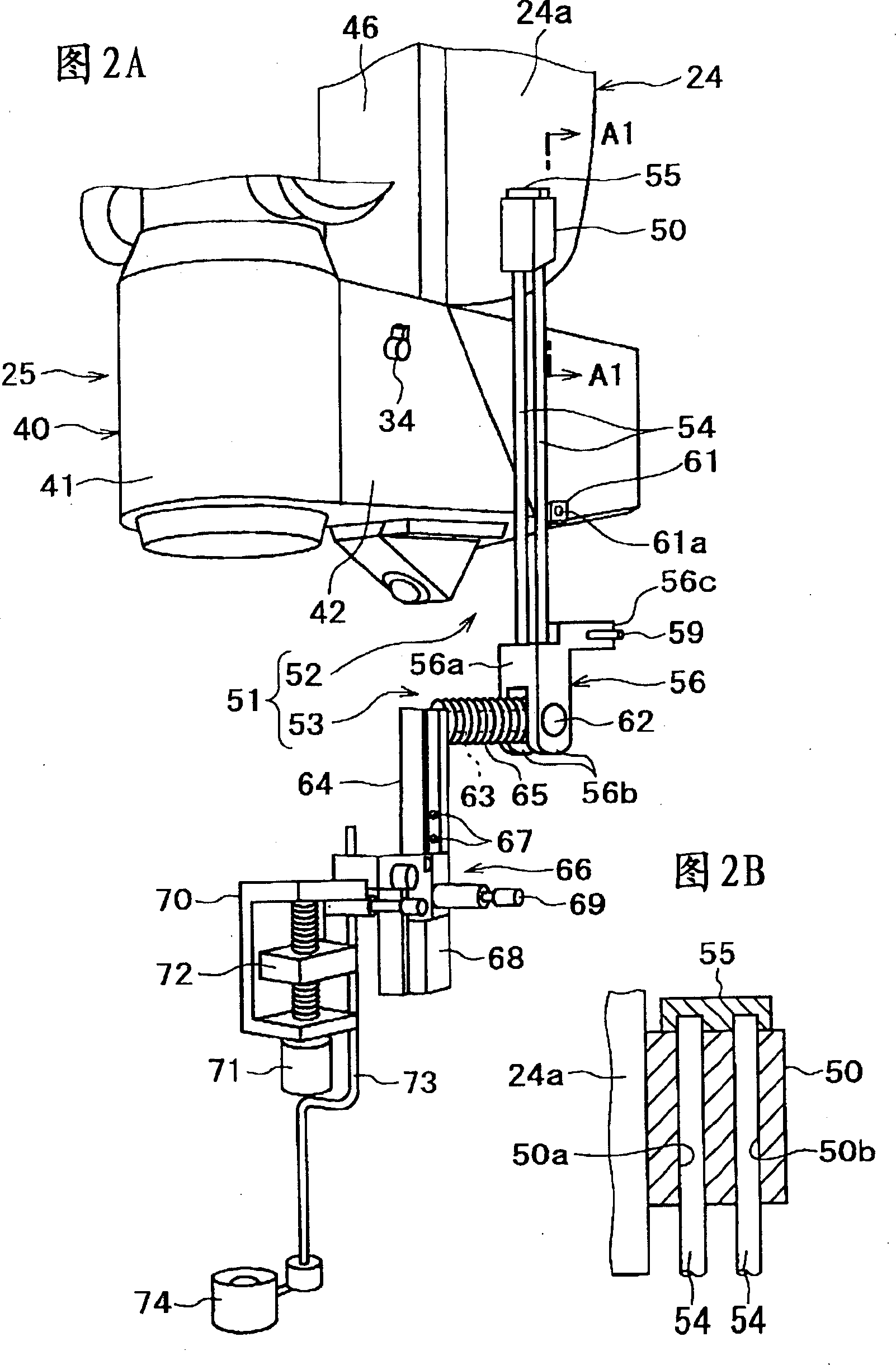

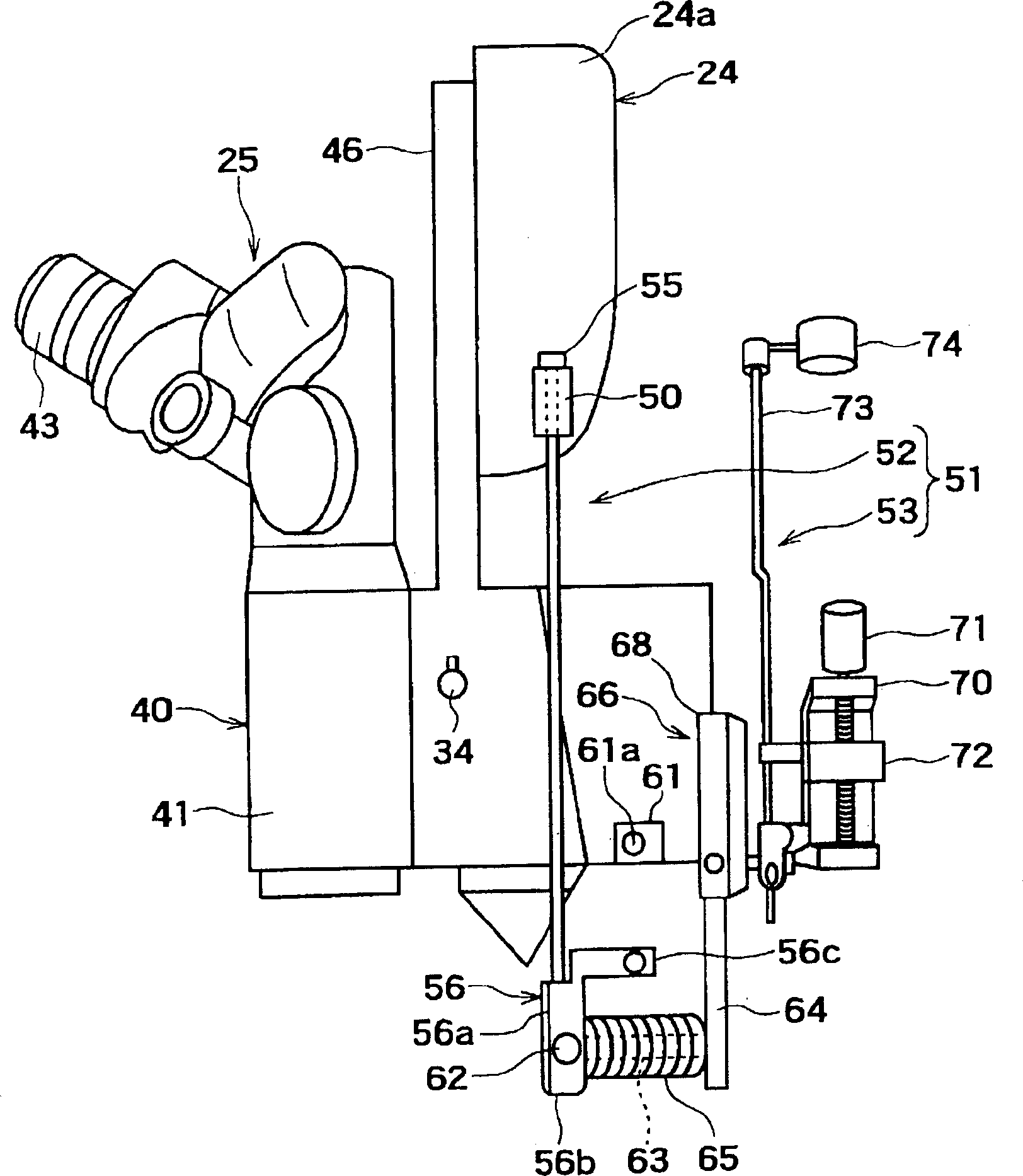

[0121] In the embodiment described above, if the operation signal from the upward coarse motion switch 30 is input to the calculation control circuit 27, the first drive motor 18 of the first electric up and down movement device 17 is controlled to make the supporting part 19 relatively At the second arm 6, the upward micromotion is performed at the speed v1, and at the same time, the second drive motor 26 of the second electric vertical movement device 24 is controlled to make the surgical microscope 25 slightly upward at the speed v2 relative to the supporting frame 23. As a result, the surgical microscope 25 is moved upward and coarsely at the speed (v1+v2) relative to the second arm 6. However, it is not limited to this configuration.

[0122] That is, when the operation signal from the ascending coarse switch 30 is input, the supporting part 19 moves at a speed V (V>>v1) relative to the second arm 6 through the first electric up and down movement device 17 through the cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com