Door lock gear

A door lock and latch technology, applied in the field of door lock devices, can solve problems such as intrusion and immersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

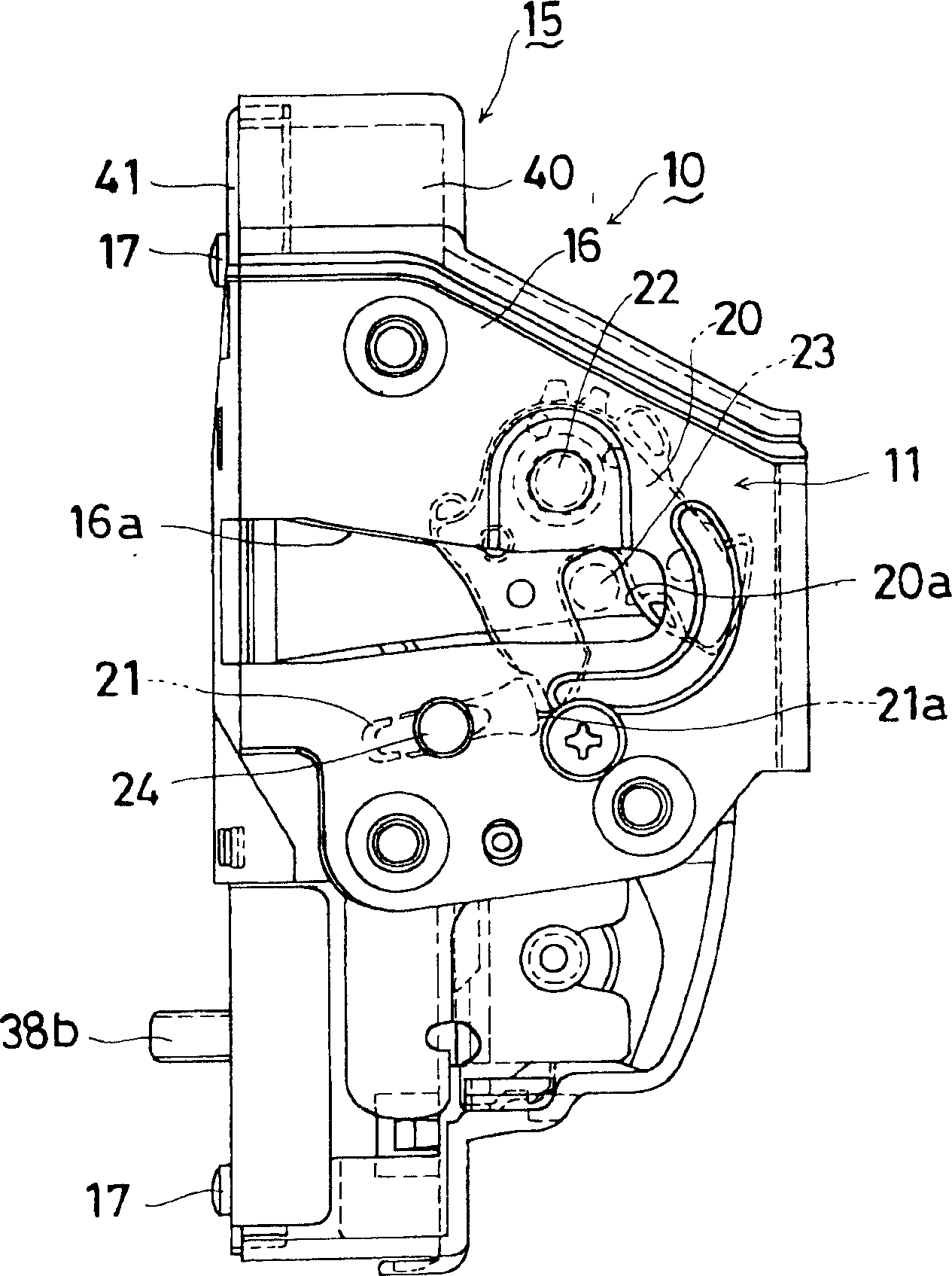

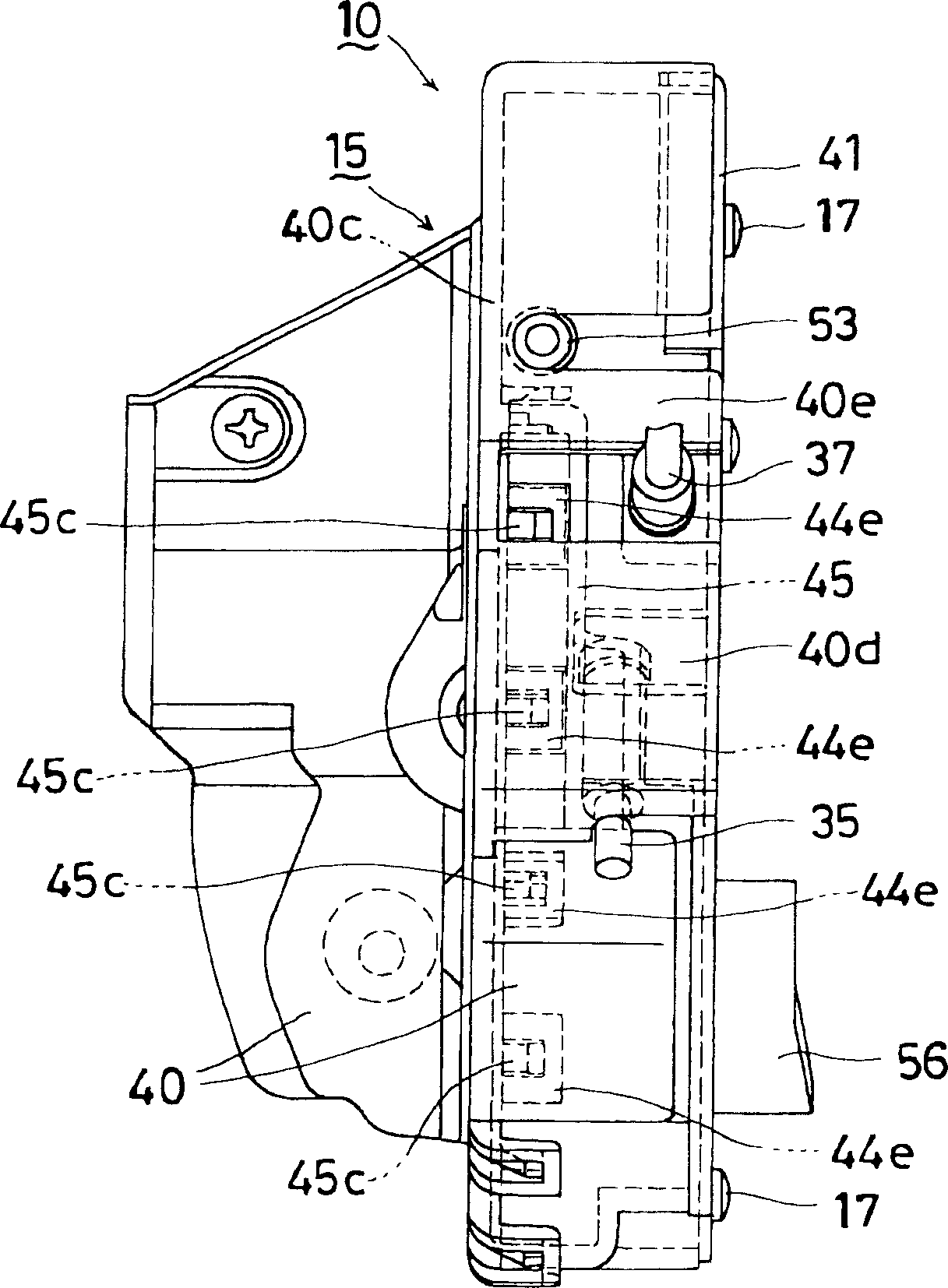

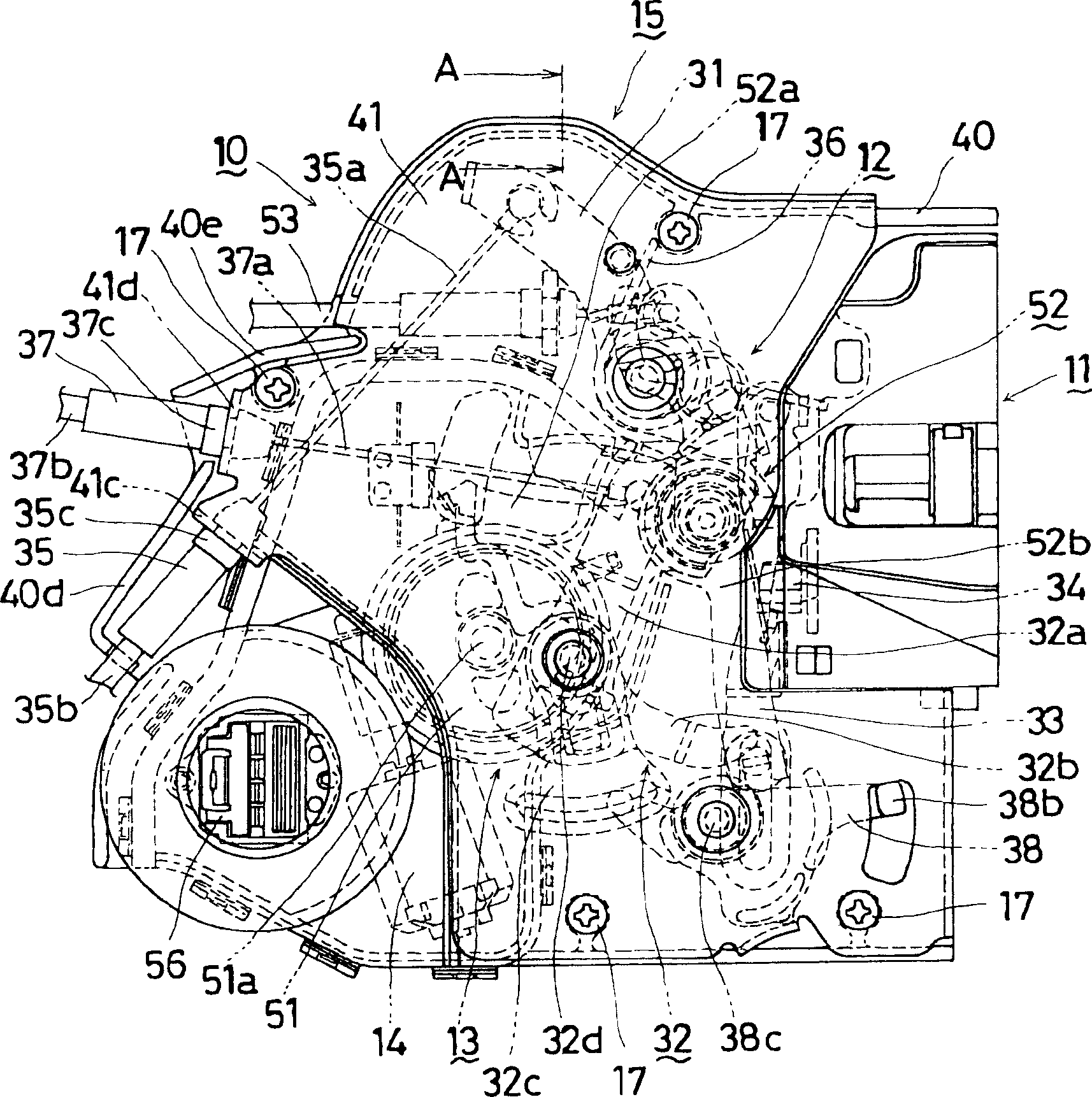

[0043] The door lock device 10 (door lock device) of the present invention is roughly composed of figure 1 The illustrated latch mechanism 11 (latch mechanism), opening unit 12 (opening unit) ( image 3 etc.), locking unit 13 (locking unit) ( image 3 etc.), motor 14 (actuator) ( image 3 etc.) constituted. These are integrally accommodated in the casing 15 (casing). This door lock device 10, its latch mechanism 11, in and figure 1The plane (hereinafter referred to as the 1st plane) that the shown paper surface develops in parallel constitutes, and the locking mechanism and the motor 14 that are made up of the opening unit 12 and the locking unit 13, are in the plane (the 2nd plane) (the 2nd plane) that develops perpendicularly with the 1st plane ( and figure 1 It is constructed in a plane developed in a direction perpendicular to the paper surface shown). Housing 15, included in the figure 2 Cover the locking mechanism and the part of the motor 14 in the shown right d...

no. 2 Embodiment approach

[0092] based on the following Figure 17 as well as Figure 18 The second embodiment will be described. In the second embodiment, compared with the first embodiment, the shape of the first inner opening lever 32a of the inner opening lever 32 is different. That is, the distance between the connection hole 32e and the canceling flange 32m of the first inside open lever 32a is shorter than that of the first embodiment.

[0093] (Opening operation inside the locked state)

[0094] In this embodiment, when the Figure 11 When the inner handle is operated in the corresponding locked state, it will act as follows. When the inside opening lever 32 rotates counterclockwise in the figure as a whole, first, the undo flange 32m of the first inside opening lever 32a presses the joining portion 52m of the resin rod 52a of the active lever 52 toward the lower left in the figure. The state after its action is as Figure 17 shown.

[0095] Along with the further movement of the inside ...

no. 3 Embodiment approach

[0100] based on the following Figure 19 The third embodiment will be described. The third embodiment differs from the first embodiment in the configurations of the casing 15 and the case 42 .

[0101] The case 15 is composed of a resin half case 61 and a resin cover 62 . On the half case 61, a flange portion 61b is formed along the peripheral end surface 61a thereof. On the other hand, in the cover 62, a groove portion 62b is formed along the peripheral end surface 62a. When the cover 62 and the half case 61 are combined, the flange portion 61b fits into the groove portion 62b, and a drain passage 63 communicating with the outside of the case 15 is formed between the fitted two peripheral end surfaces 61a, 62a.

[0102] The case body 42 is composed of a resin half case 64 and a resin cover 65 . The half-box 64 shares a reference wall 61c with the half-shell 61, and has a wall 64a protruding from the reference wall 61c. On the wall 64a of the case half 64, a groove portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com