Imbeded type electric hoister

A car crane and embedded technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of unsafety, safety and maintenance hidden dangers, time-consuming and other problems, and achieve the effect of ensuring safe use and timely maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

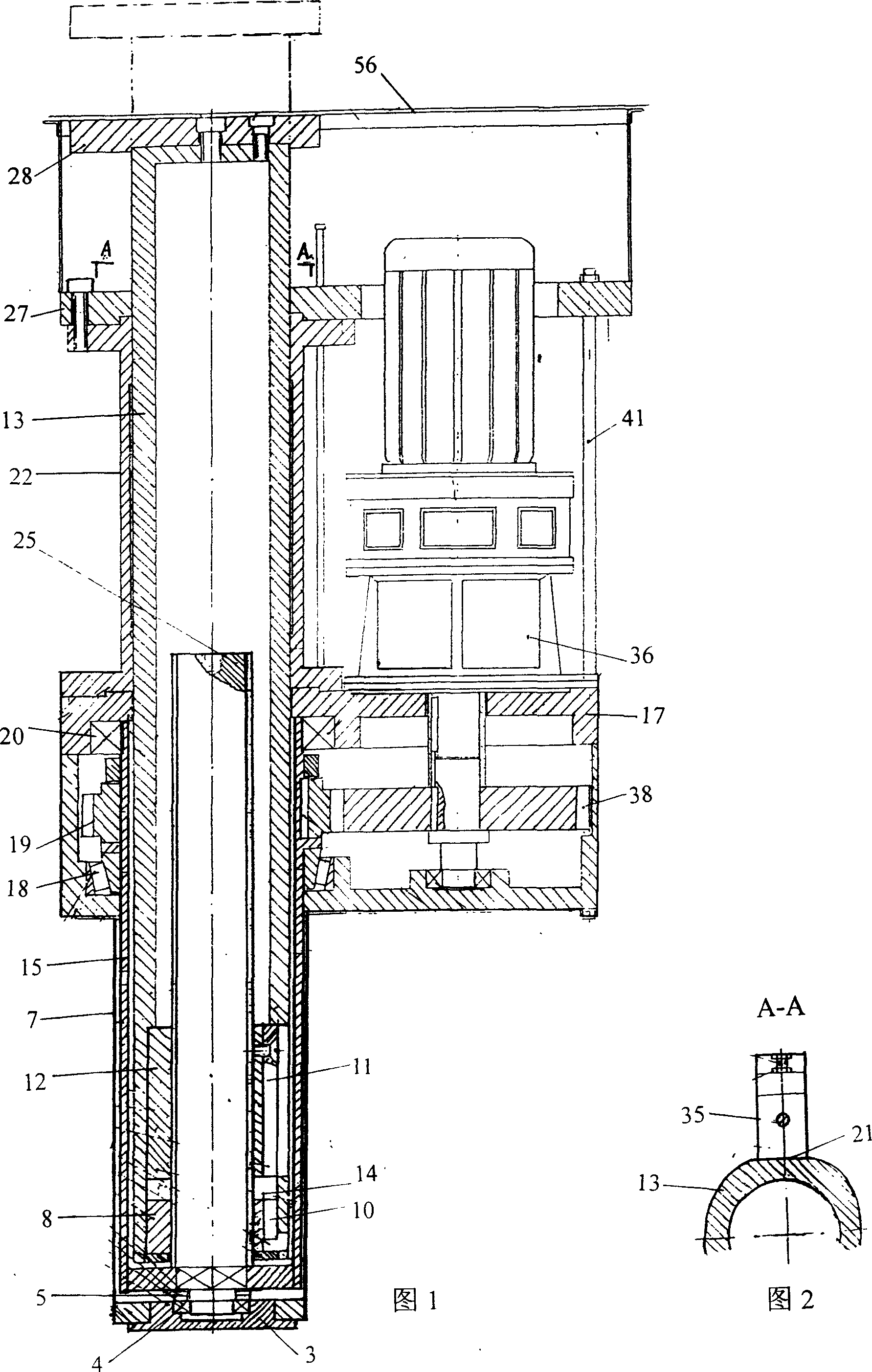

[0017] Referring to Figure 1 and Figure 2, the embedded electric car crane includes the following components:

[0018] 1) Machine base: including frame type bearing frame 27, bearing frame cover plate 56, fixed on the bottom plate of the bearing frame, sleeve 22 for supporting the lifting cylinder, gear box 17 and reducer 36 In the illustrated example, the gearbox 17 is fixed to the bottom of the sleeve 22 by bolts and tie rods 41. The gear box 17 has a driven gear 19 and a driving gear 38 that mesh with each other. The driven gear 19 is coaxial with the sleeve 22. The driving gear 38 is installed on the output shaft of the reducer 36. The reducer can adopt a cycloidal pin wheel. Reducer or gear speed or worm gear reducer.

[0019] 2) Lifting mechanism:

[0020] It includes a screw 25 coaxially sleeved from inside to outside, a lifting cylinder 13, a rotating cylinder 15 and an oil cylinder 7 whose bottom is sealed with an end cover 3. The axis coincides with the axis of the sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com