Pickup camera self calibration method based on robot motion

A technology of robot movement and camera, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of camera movement limitation and strictness, and achieve the effect of meeting the needs of visual measurement

Inactive Publication Date: 2005-03-09

INST OF AUTOMATION CHINESE ACAD OF SCI

View PDF0 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The defect of the current camera self-calibration technology is that the restrictions on camera movement are relatively strict

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0035] The camera calibrated in Example 1 has been applied to the seam tracking of the arc welding robot. The camera calibrated in Example 2 has been applied to the positioning and navigation of mobile robots.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

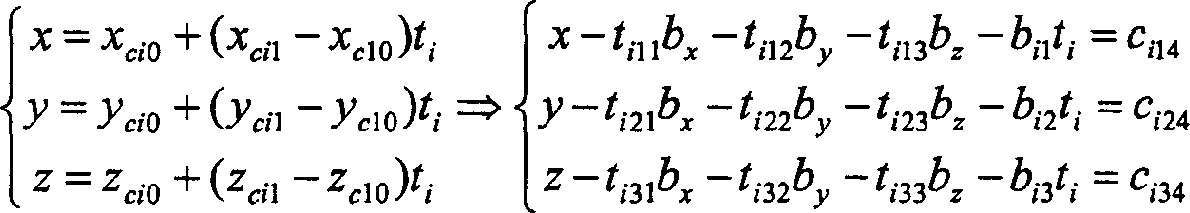

A self-calibrating method based on the movement of robot for the camera installed to terminal end of robot includes choosing a point ni the visual field of camera as a characteristic origin point, arbitrarily moving the terminal end of robot several times without changing its posture to obtain more characteristic origin points, using the least square method to obtain the internal and external parameters of camera, changing its postures, obtaining several space straight line from the center of optical axis and the imaging dots on image plane, using their intersection point to calibrate the position of characteristic point in basic coordinate system, and calculating the external parameter of terminal end.

Description

technical field [0001] The invention relates to a camera calibration technology in the field of robot vision control, in particular to a method for obtaining internal and external parameters of a camera. technical background [0002] Traditionally, the camera is calibrated by using the calibration reference object-target. Specifically, a calibration reference object of known shape and size is placed in front of the camera, and the internal and external parameters of the camera are calculated by measuring the imaging position of the reference object on the image plane. . In practical applications, it is not allowed to place a specific calibration reference object in the environment in many cases. Therefore, the camera calibration technology (ie, self-calibration technology) that does not require a specific calibration reference object has received more and more attention. This technology is used in robots. It has broad application prospects in hand-eye system and head-hand s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B25J13/08

Inventor 徐德谭民

Owner INST OF AUTOMATION CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com