Electrical ionizer

A technology of ionizers and ions, applied in the field of ionizers, can solve problems such as cost and control circuit generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] best practice

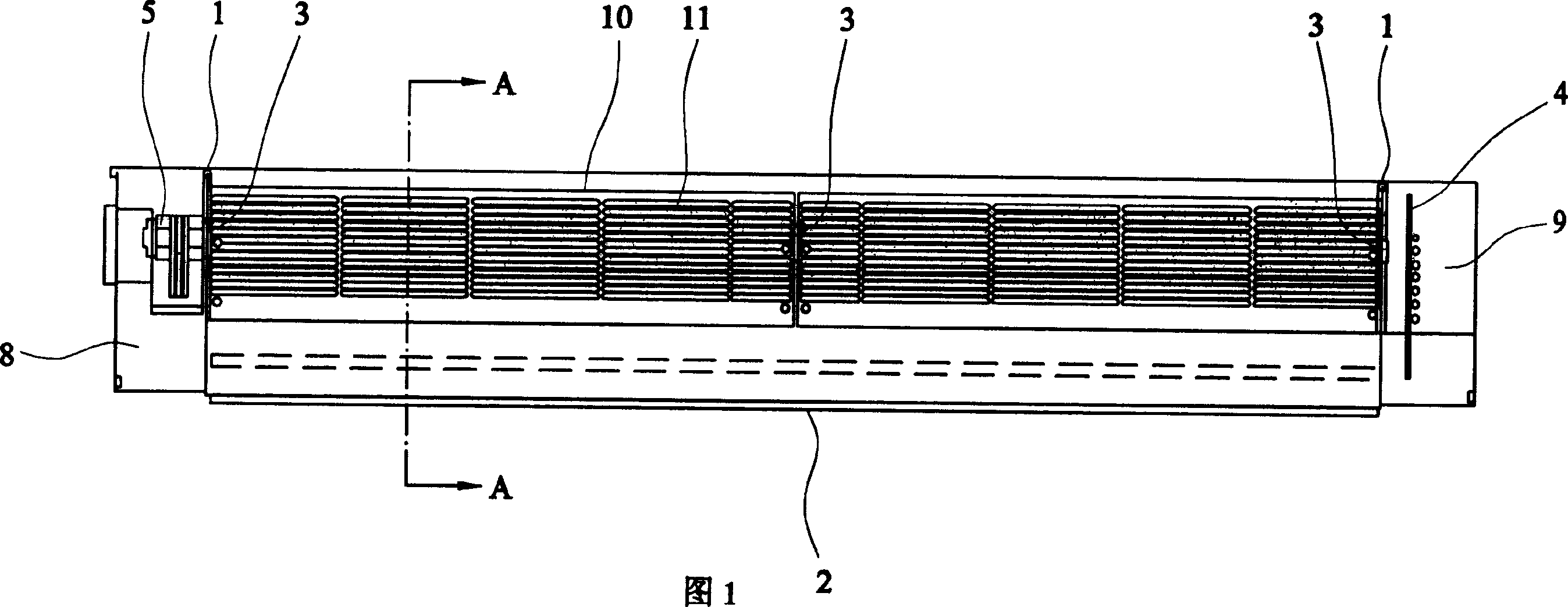

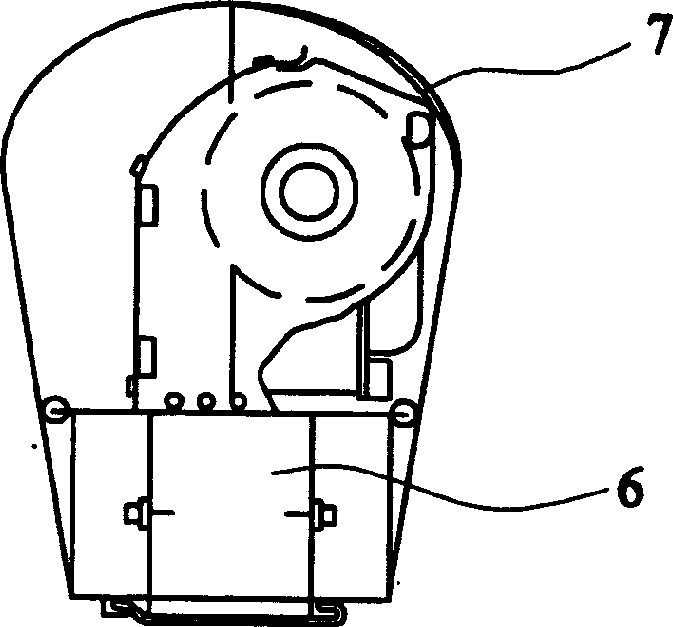

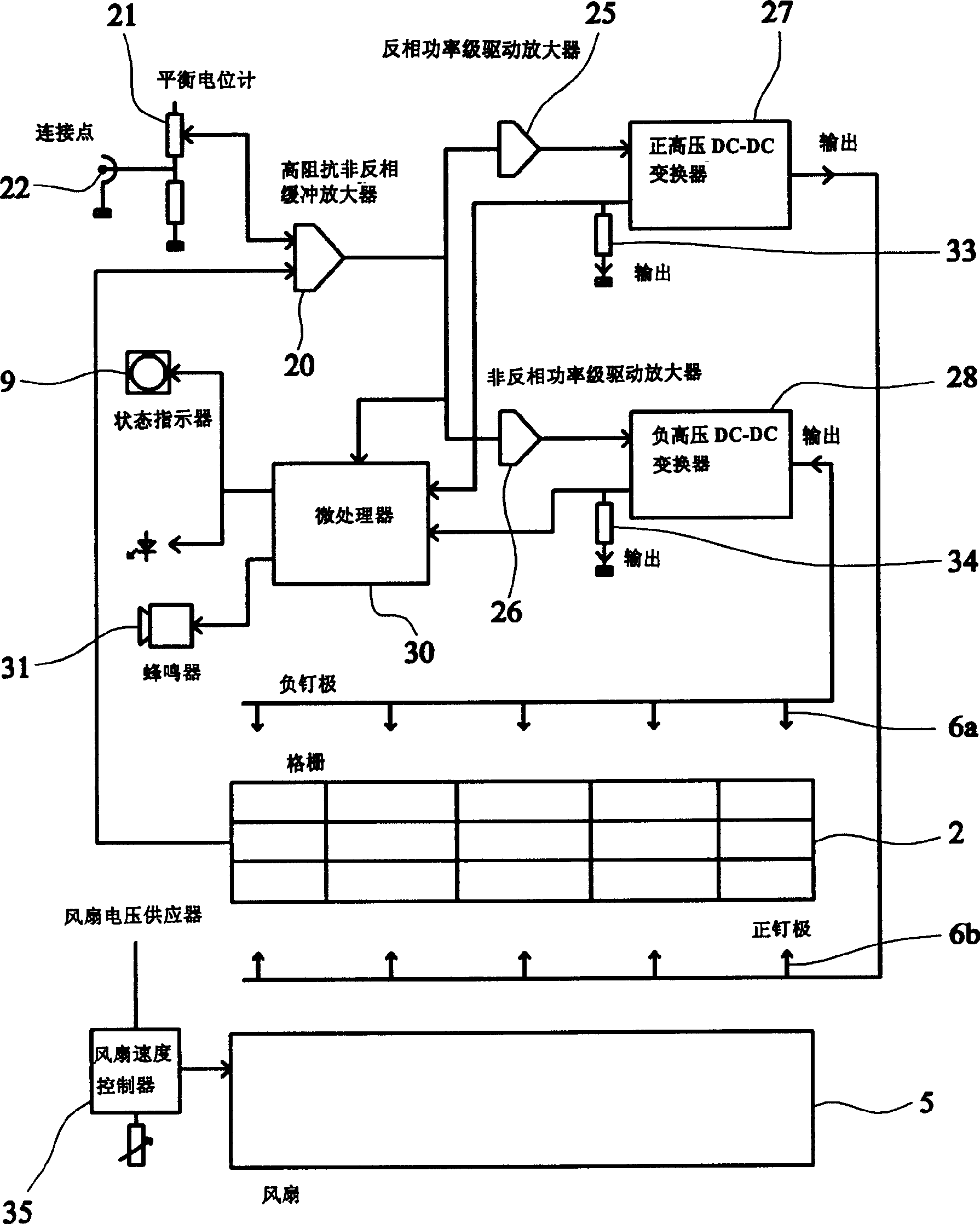

[0029] Figures 1 and 2 illustrate an ionizer suitable for use in a cleanroom environment in accordance with one embodiment of the present invention. The ionizer comprises: a cross-flow fan with an impeller 10 driven by an impeller motor 5 and housed in a casing 7 . The housing is made of stainless steel (other materials suitable for cleanroom environments are also available) and has a "teardrop" profile (such as figure 2 shown). This shape positions the ionizer in the laminar downdraft airflow impinging in the clean room without unduly disturbing the airflow.

[0030] Air enters the unit through inlet 11 and exits through outlet 12 . A partition 1 is provided on each end of the unit and is sealed to the housing 7 by means of a gasket in order to confine the air flow to the desired part of the unit. The partition 1 also prevents particulate contamination generated by the motor 5 and associated control electronics from entering the air stream.

[0031...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com