Portable grinding machine

A grinding tool, portable technology, applied in the field of portable grinding tools, to achieve the effect of improving clamping reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

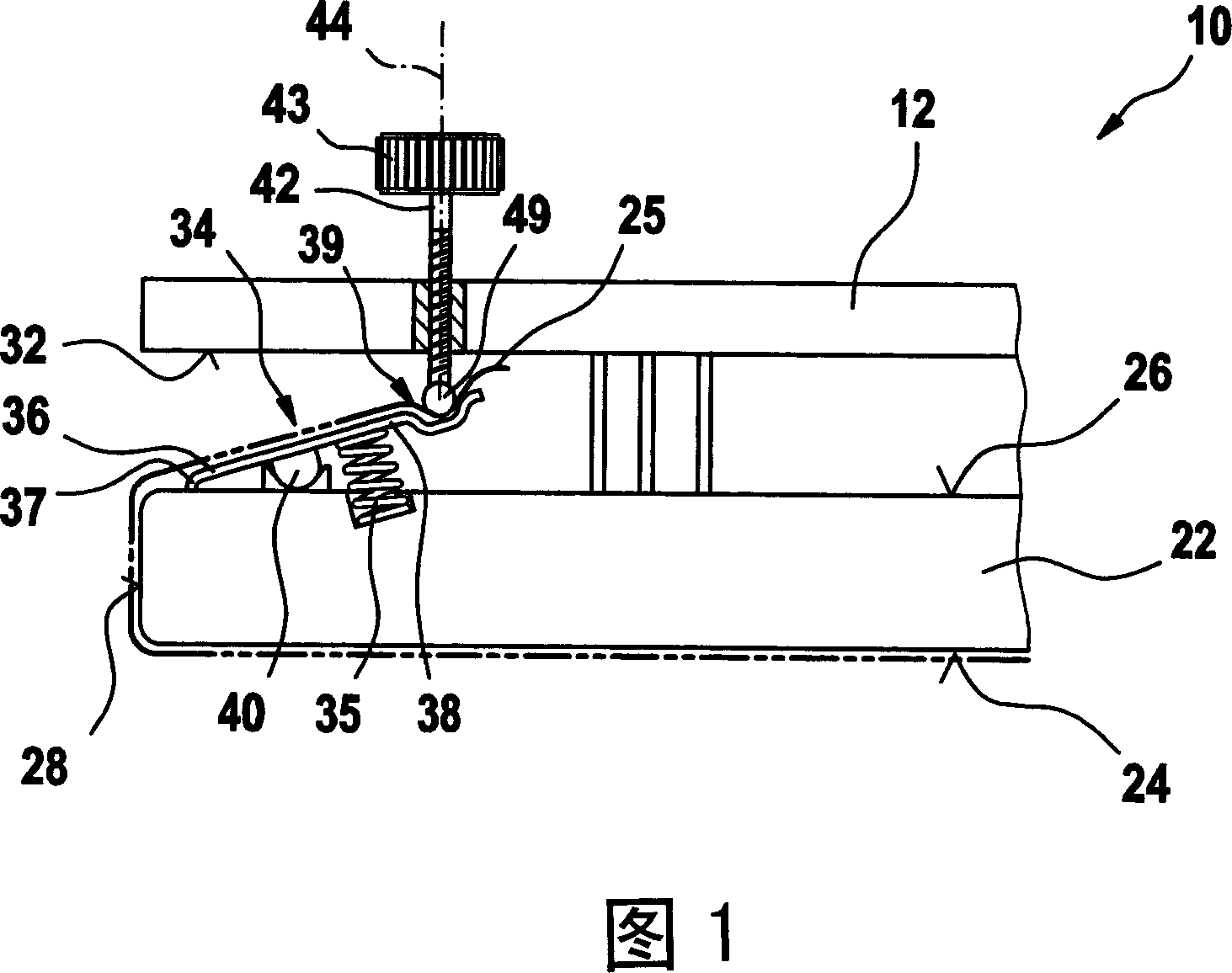

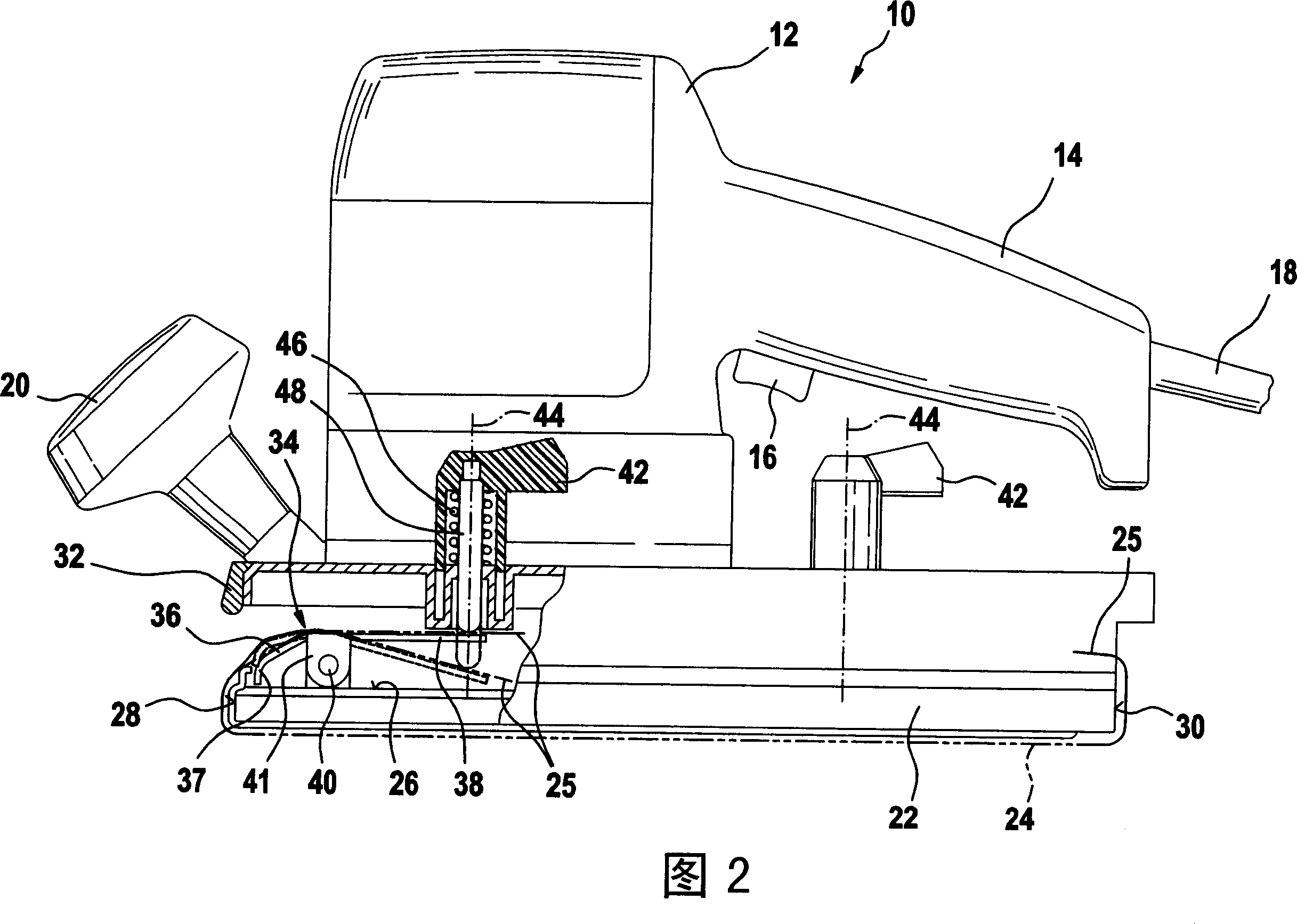

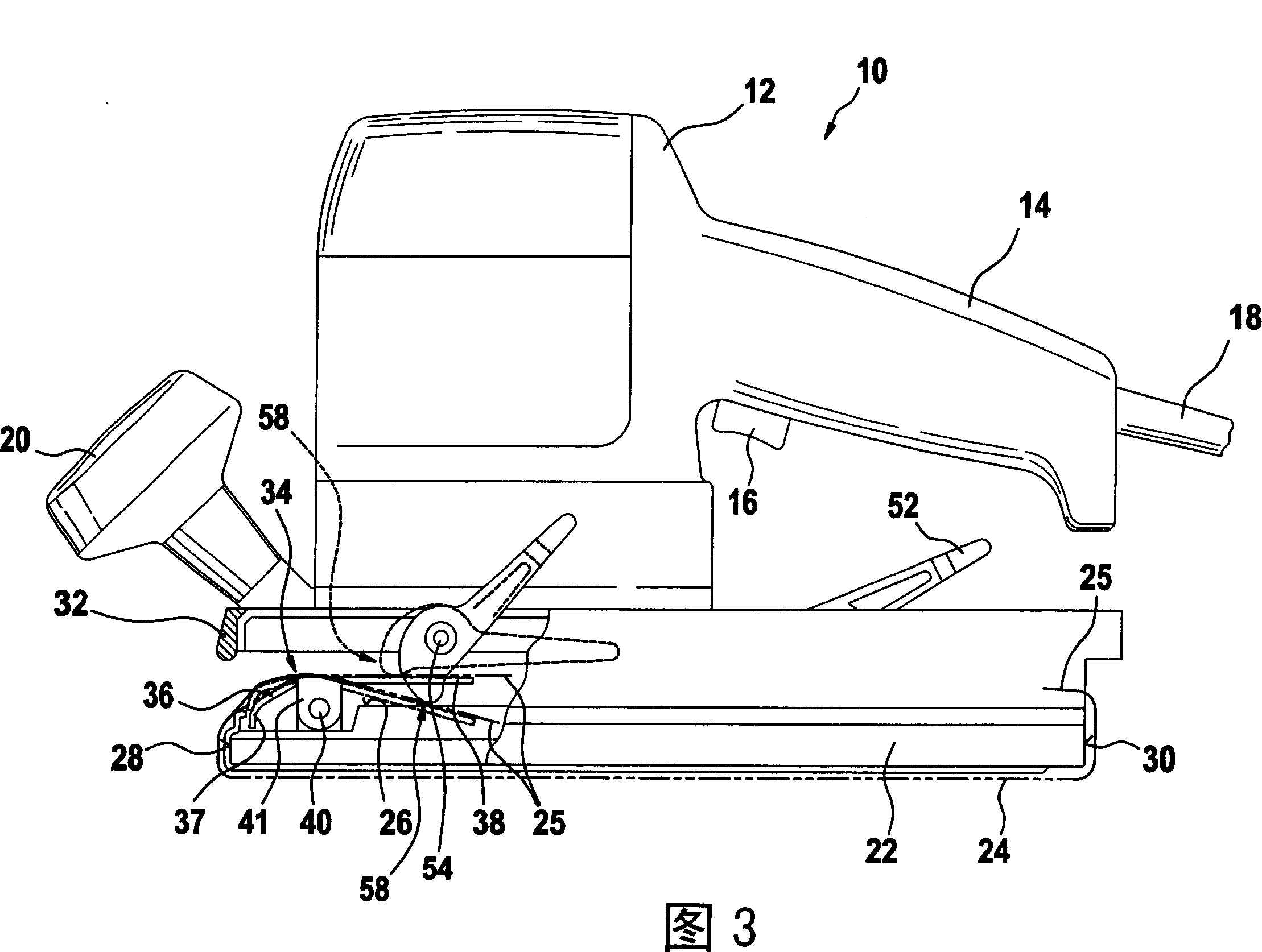

[0027] figure 1 A partial side view of a portable grinding tool 10 is shown. Its grinding disc 22 is visible in the region of its front edge 28 with a grinding blade 24 held thereon. The grinding disc 24 is wound along the underside of the grinding disc 22 and its front edge 28 and guided onto its upper side 26 . In this case, the grinding disc end 25 is placed on a pivot frame 34, wherein the end is first guided via the lever arm 36 close to the edge as far as its lever arm 38 facing away from the edge, and there it is guided in a transverse direction. A positively fitted clamping arm 49 in the groove 39 can be pressed into this transverse groove 39 with a non-illustrated friction-enhancing lining. Through the rotation of the rotary knob 43 and the axial downward movement of the rotary clamping rod 42 about its axis of rotation 44, the grinding disc end 25 is fixed against undesired loosening between the clamping arm 49 and the transverse groove 39 and through the The rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com