Loading device to transfer items from a movable platform

A technology of loading equipment and mobile equipment, applied in the direction of conveyor objects, transportation and packaging, conveyor control devices, etc., which can solve the problems of manual labor of employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

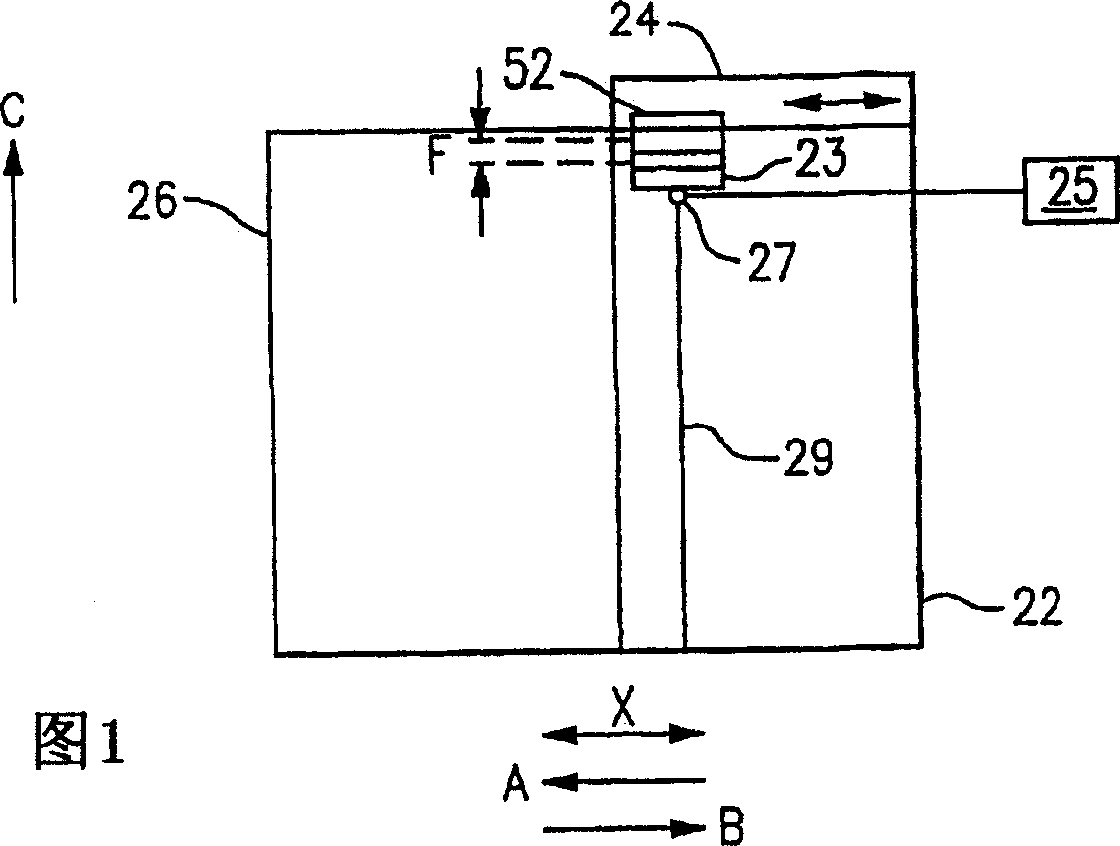

[0015] As shown in FIG. 1 , the loading device 24 is used to transfer items 52 from the first member 22 to the second member 26 according to the demand for the items 52 . In one embodiment, the first member 22 is a freezing member and the second member 26 is a cooking member, and the loading device 24 is used to transfer items 52, such as food.

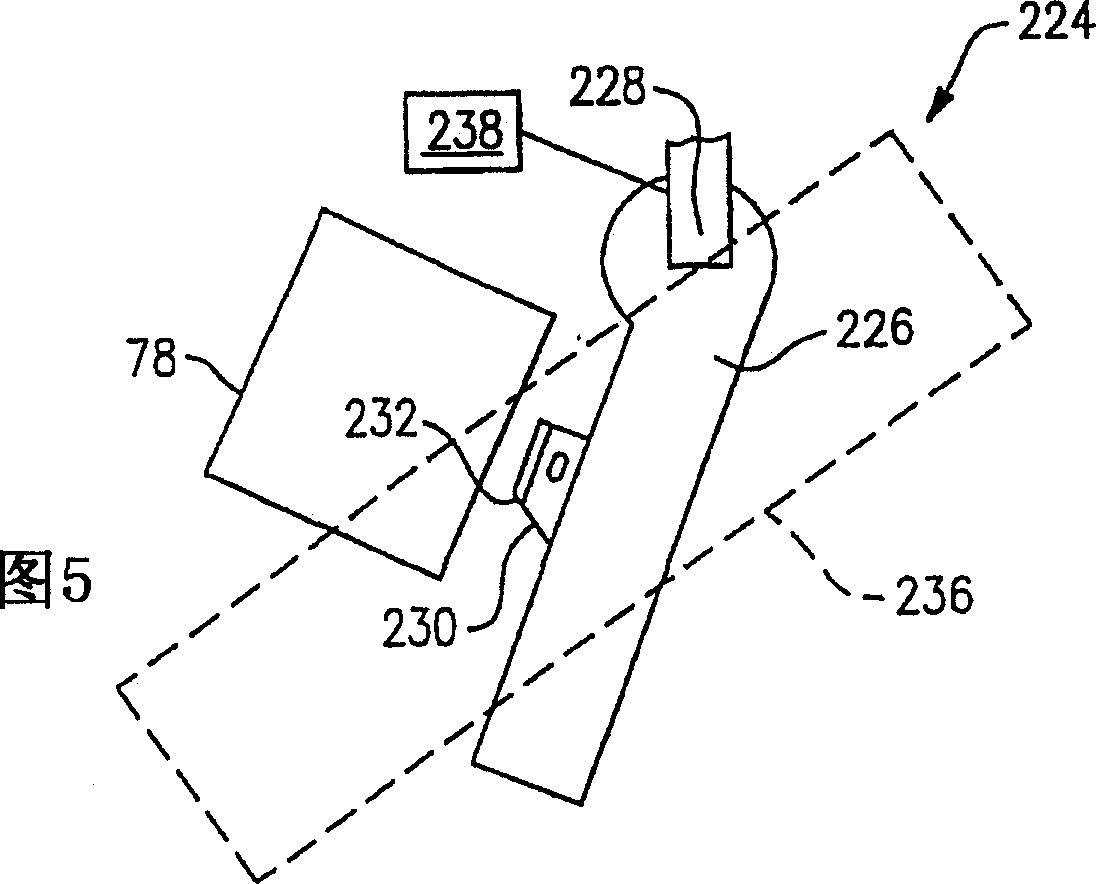

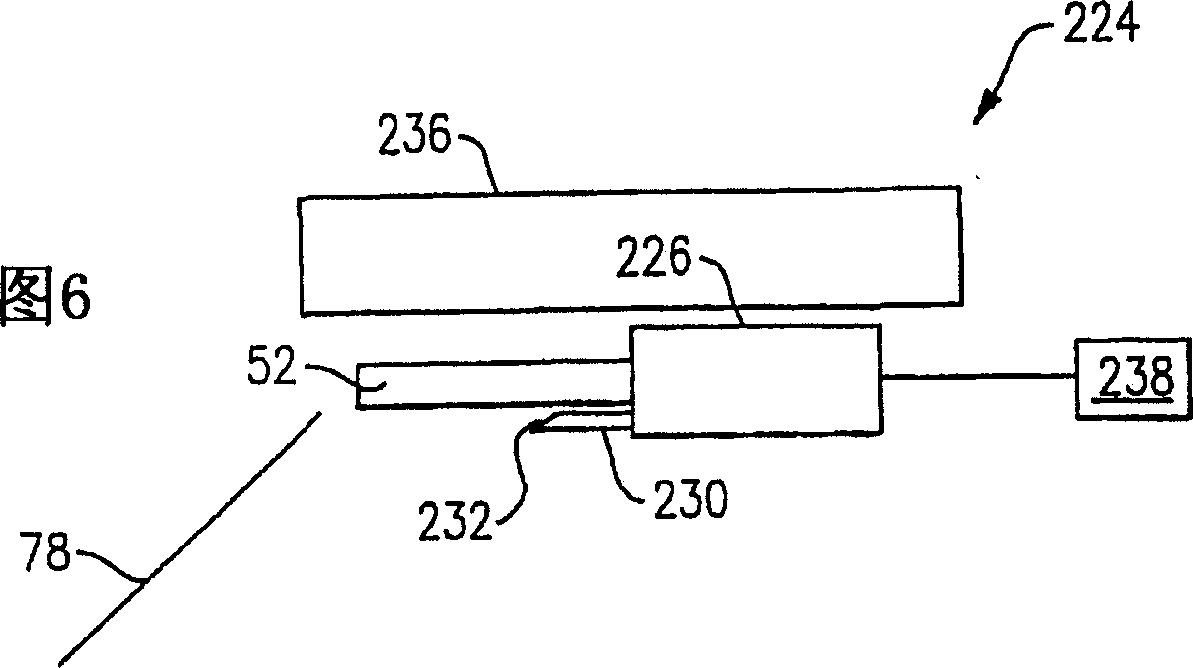

[0016] Figures 2 to 4 An embodiment of a loading device 24 is schematically shown in . The illustrated loading device 24 includes a motor 70 that can move in the X direction (i.e. Figures 2 to 4 The feeder 66 that moves in the left and right direction). The feeder 66 includes a cutout 68 extending partially across the height h of the feeder 66 . Cutout 68 is preferably the same shape as article 52 . A sensor 72 is located on an upper surface 74 of the cutout 68 .

[0017] image 3 The feeder 66 is shown in the loading position. When the article 52 moves into the cutout 68 and the sensor 72 detects that the article 52 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com