Sharpening method of wavy edge of different material for cutter

A cutting edge and cutting knife technology, which is applied in the field of CNC cutting and grinding technology, can solve the problem that the wave-shaped cutting edge of the special-shaped cutting knife cannot be edged and ground by the numerical control grinding process, and the quality of manual cutting and grinding is difficult. , can not be described by equations in the Cartesian coordinate system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

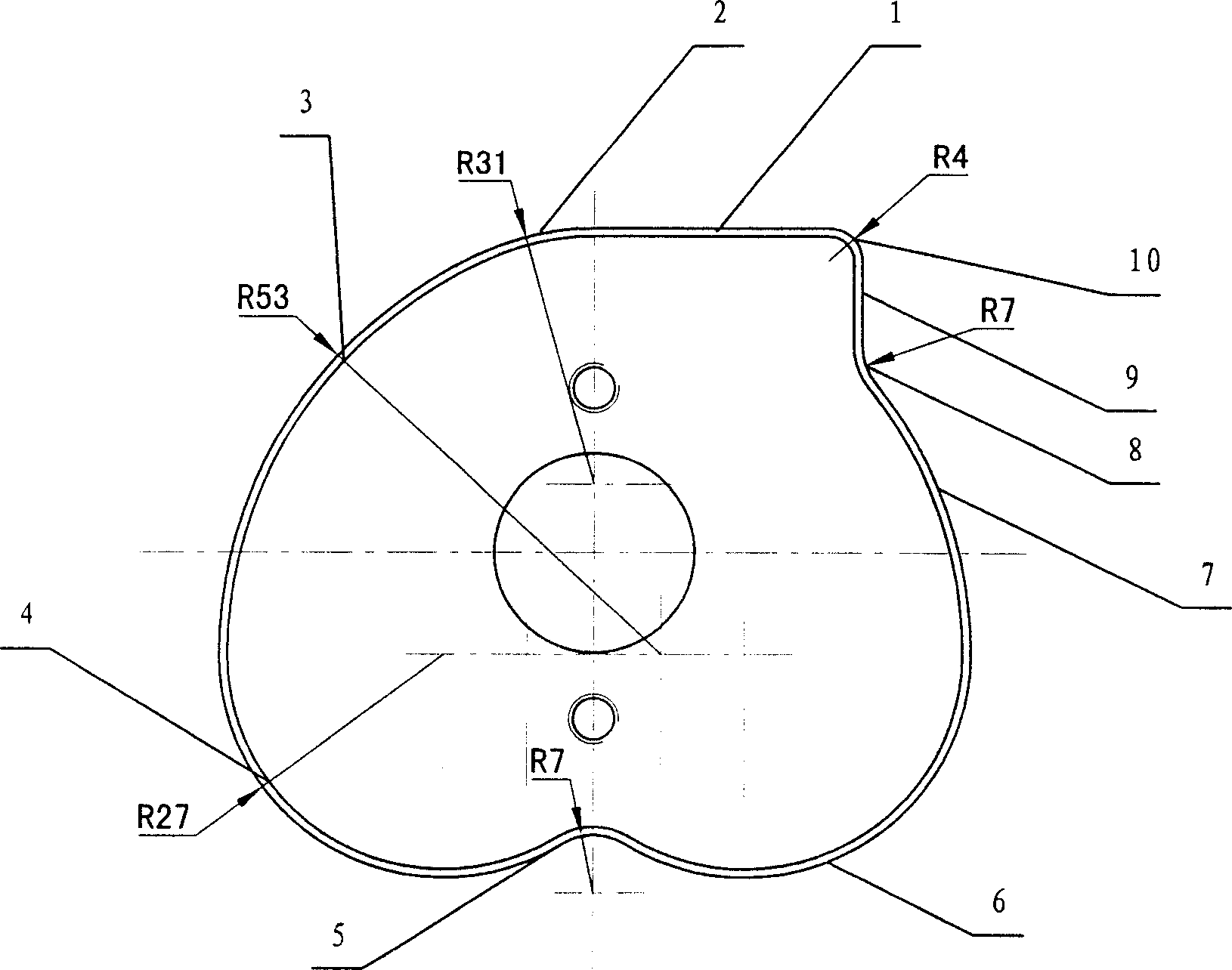

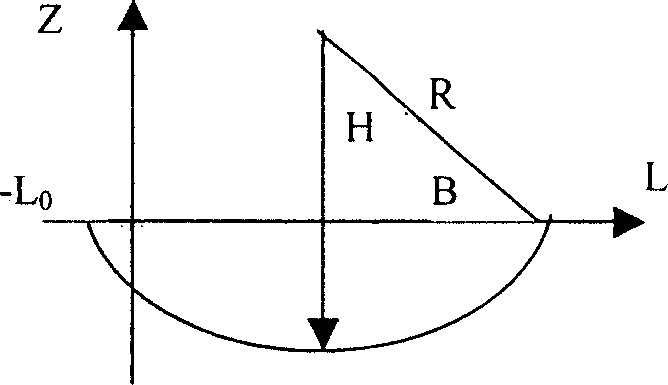

[0080] Embodiment: Use the method of the present invention to sharpen the wavy edge of a peach-shaped cutter.

[0081] point number

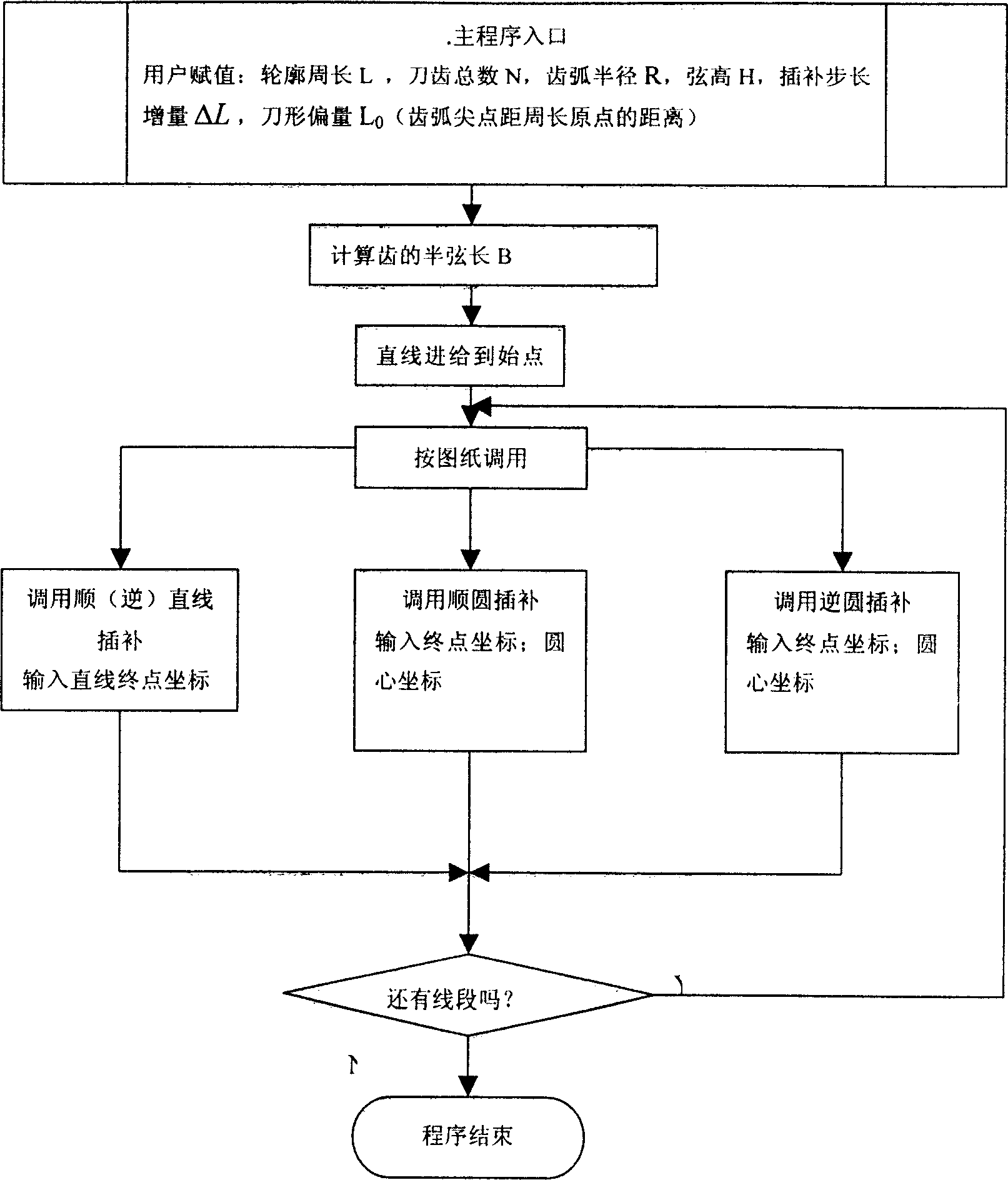

[0082] According to the three patented methods disclosed in this patent and program block diagram programming, after inputting the program of the patented method to be adopted into the CNC machine tool with parameter programming function, and then input the parameters of the peach-shaped cutter into the CNC machine tool, the CNC machine tool will immediately According to the operation steps of the patented method, the sharpening or sharpening of the knife edge is automatically realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com