Universal refill mechanism and method

A technology of refill and structure, which is applied in the field of writing devices, can solve the problems of collecting chucks such as complex cost, expensive, and inconvenient manual adjustment for consumers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

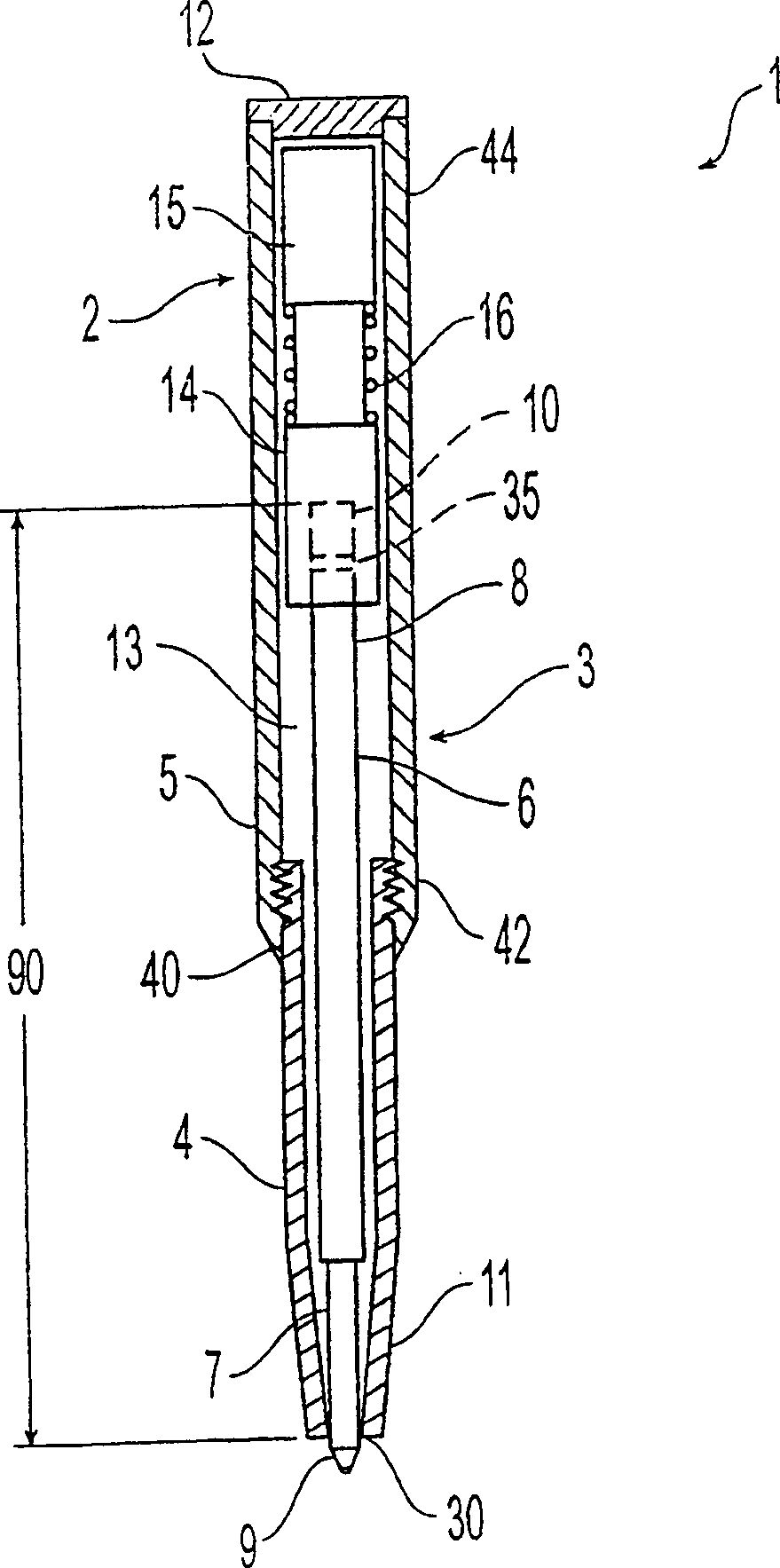

[0030] figure 1 An embodiment of a writing instrument 1 having a refill base mechanism 2 formed in accordance with the principles of the present invention is shown. Writing instrument 1 comprises a substantially hollow housing 3 comprising a lower part 4 and an upper part 5 . The lower part 4 has a generally tapered end 11 at the end terminating in an aperture 30 through which the refill cartridge 6 can protrude, and a connecting end 40 opposite the tapered end 11 . The upper part 5 has a connecting end 42 at one extremity and, opposite the connecting end 42 , a closed end 44 terminating in the end cap 12 . The end cap 12 may be a separate component attached to or inserted into the closed end 44 , or the end cap 12 may be formed as part of the closed end 44 . In the embodiment shown, the lower and upper parts 4, 5 can be rotatably connected by means of threaded connections at the connection ends 40, 42 of the lower and upper parts 4, 5, respectively. It will be appreciated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com