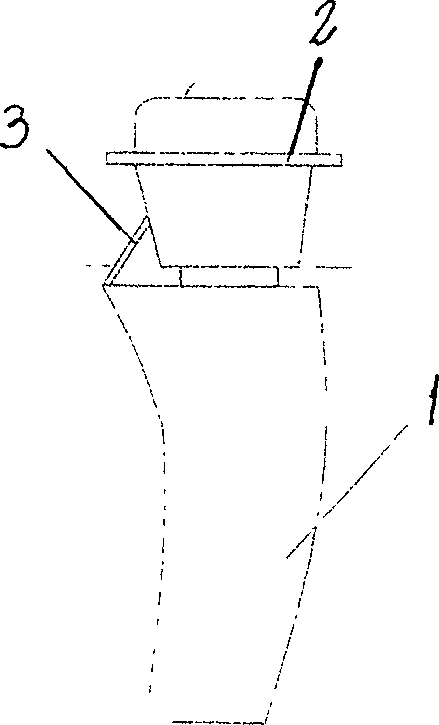

Fine casting method for super long lower pressure partition guide blade of turbine in stainless steel investment mold

A technology of investment casting and steam turbine, which is applied in the field of metal precision casting and can solve problems such as introducing technical details

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

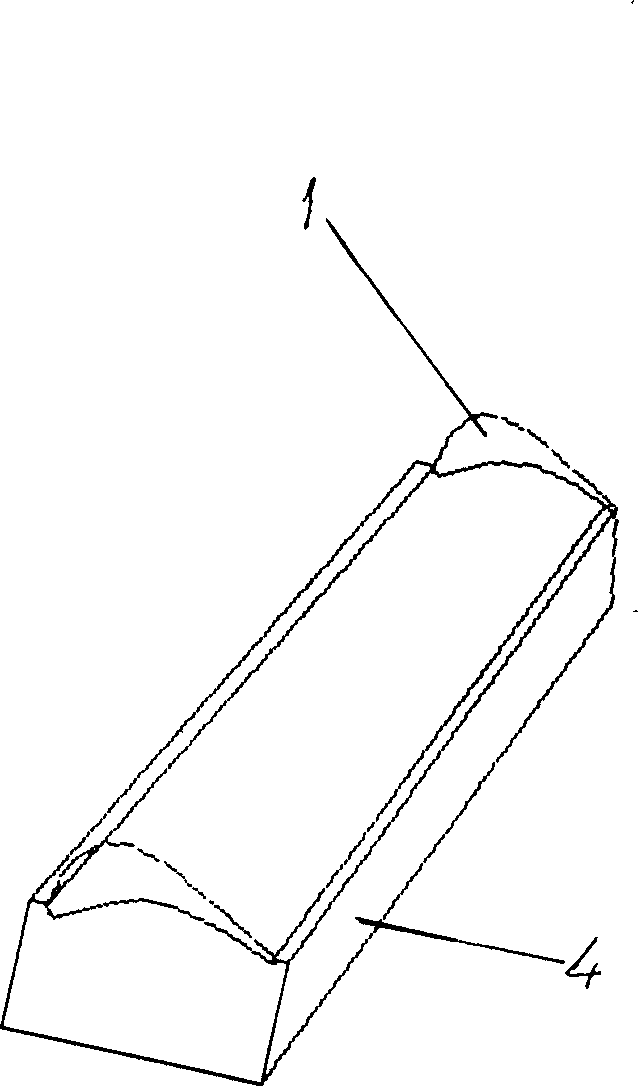

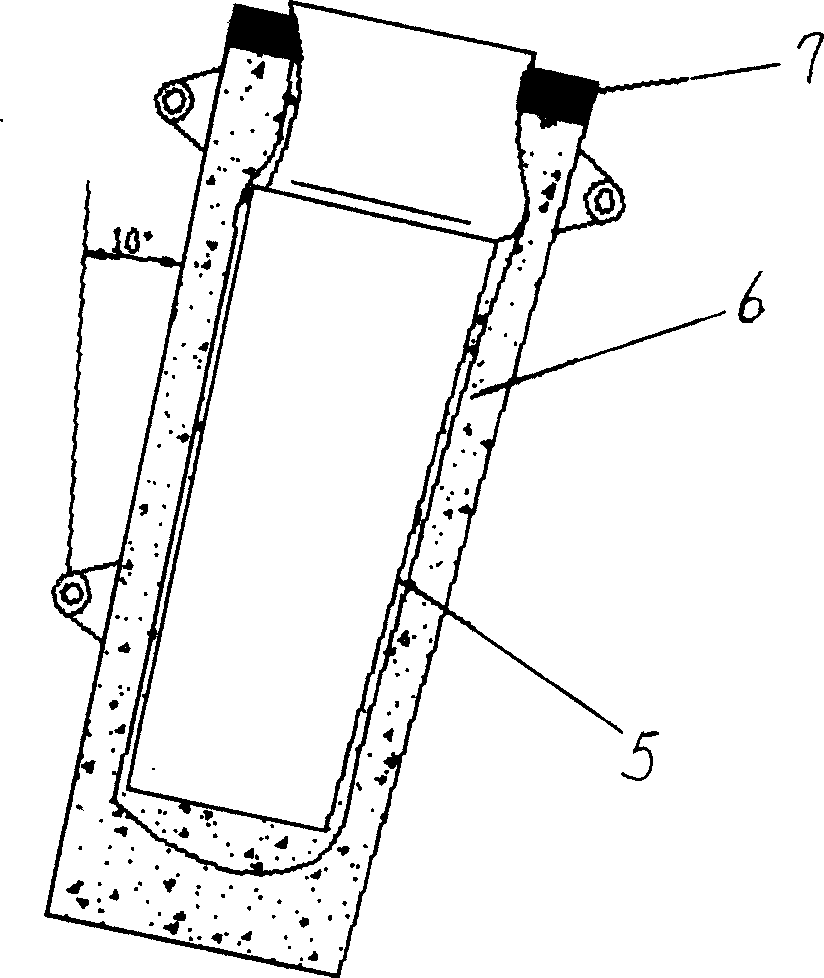

Embodiment Construction

[0039] The present invention selects a profile structure for pressing a single piece at one time, and the total shrinkage rate of the cavity is 2.5%. In the profiling design and manufacturing process, according to the characteristics of the blade itself, the actual situation such as uneven thickness, add appropriate process corrections to the parts that are difficult to predict and the deformation is not very regular. That is, at the steam inlet side where the hot joints are relatively concentrated, and the back arc is thinner, a part of the amount is worn off relative to the profiling part. Find out the regularity of blade deformation by exploring a certain number of blades. Calculate the light leakage value of each section of each blade relative to the detection sample, calculate the absolute value of the deformation part, and correct the cavity of the pressure type at the corresponding position of the pressure type.

[0040] In the selection of mold materials, paraffin wax...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com