Shift assist projection for bicycle sprocket

A protruding part and auxiliary part technology, applied in the field of gear shift auxiliary protruding parts, can solve the problems of inability to shift operation, unsatisfactory feeling of the cyclist, stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

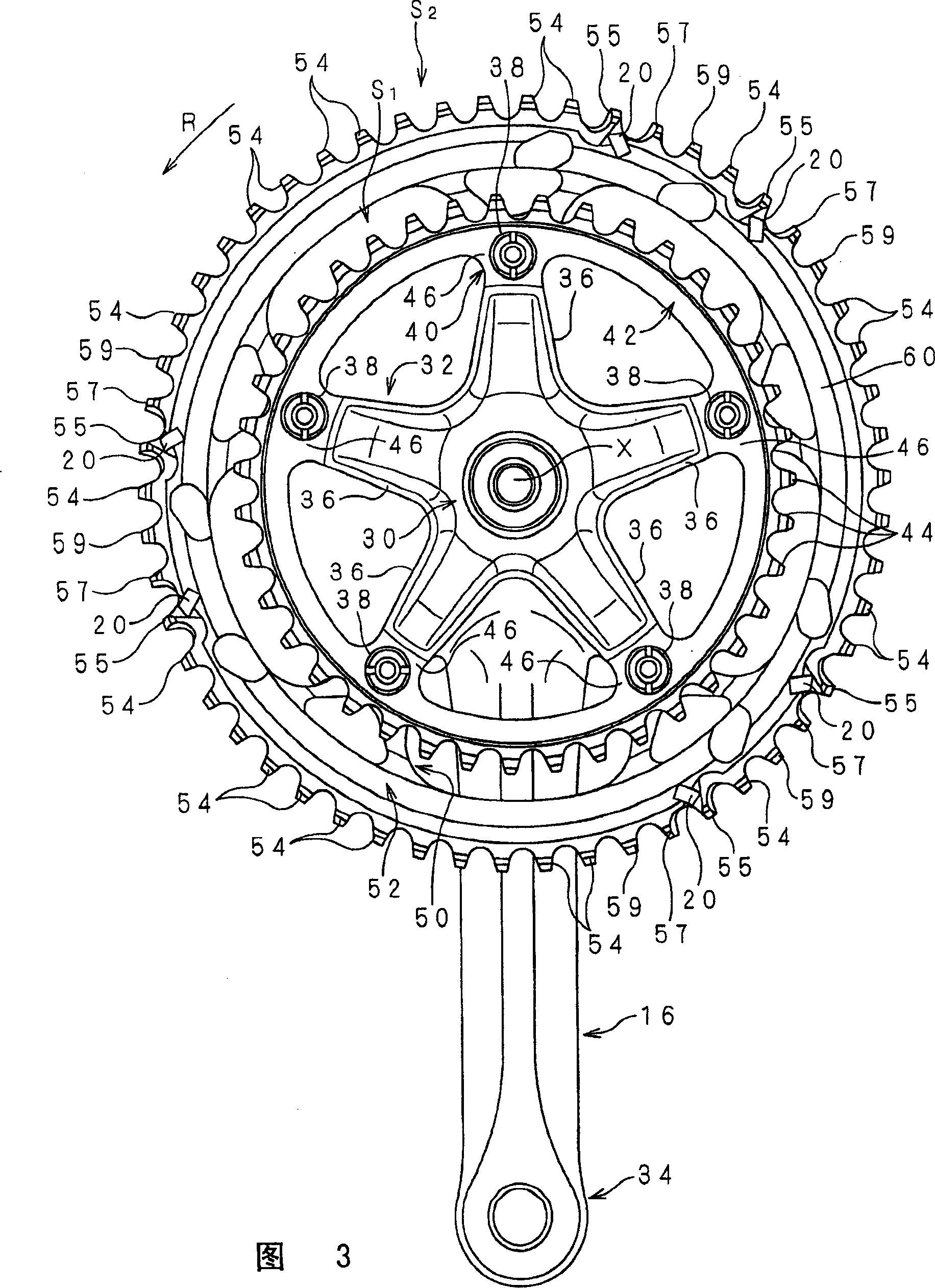

[0066] see now Figure 22 , the bicycle drive train 210 with the front crankset 212 according to the second embodiment will now be described. In addition to the sprocket S in the first embodiment 1 by a pair of sprockets S 1A and S 1B Except for substitutions, this second embodiment is the same as the first embodiment. In view of the similarity between the first and second embodiments, parts of the second embodiment that are identical to parts of the first embodiment will be given the same reference numerals. Also, descriptions of the parts of the second embodiment that are the same as those of the first embodiment may be omitted for the sake of brevity.

[0067] In this embodiment, the large sprocket S 2 and intermediate sprocket S 1B Both have a shift assist projection (not shown) as in the first embodiment. except intermediate sprocket S 1B with multiple protrusions (not shown) and similar to the large sprocket S 2 Except for the upshift teeth (not shown), the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com