Paper feeder of printer

A technology for a paper feeding device and a printer, which is applied to the printing device, printing and other directions, can solve the problem that the opening/closing action of the pinch roller is not fully automatic, and achieves suppression of enlargement and cost increase, rapid printing action, The effect of preventing skew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

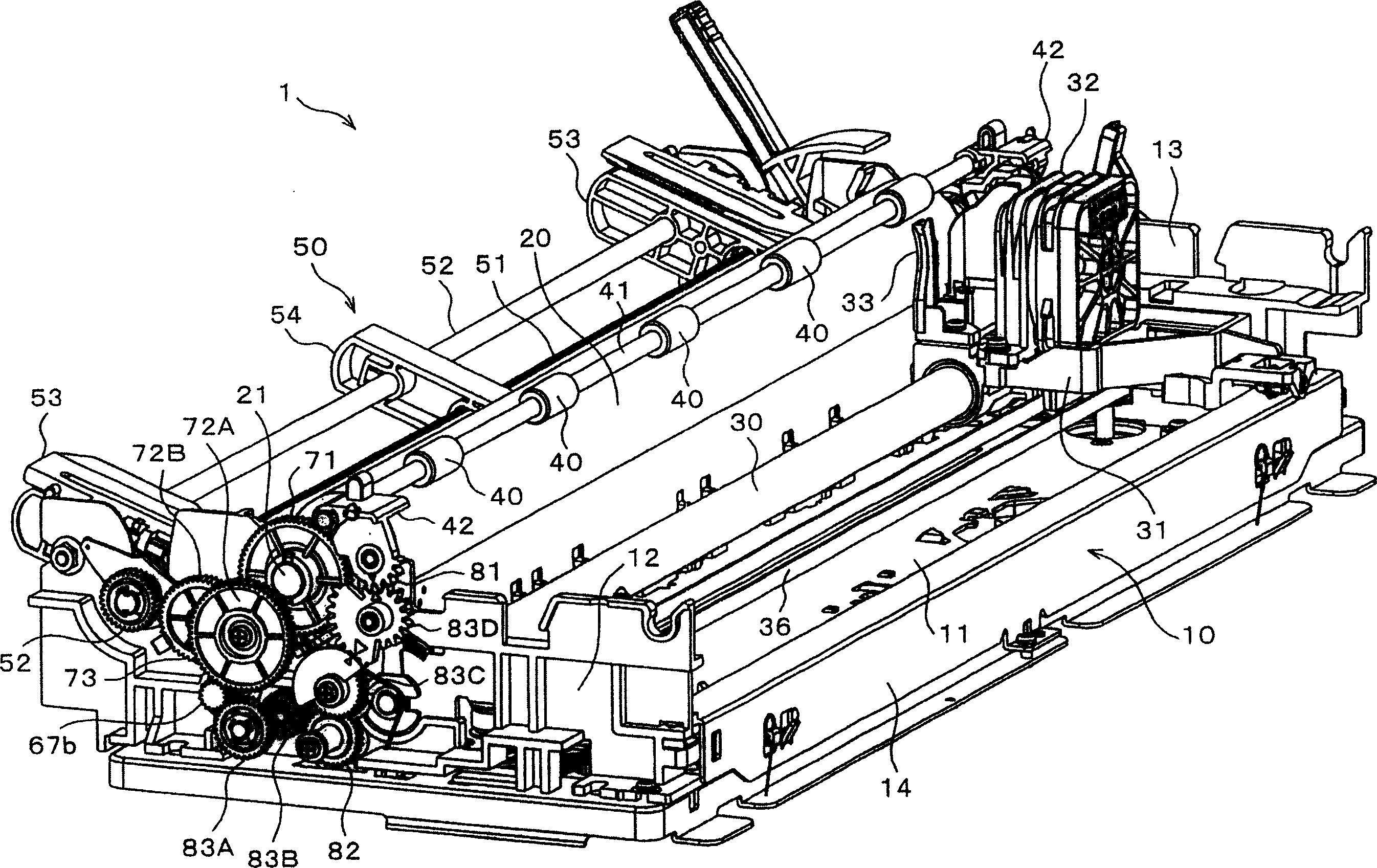

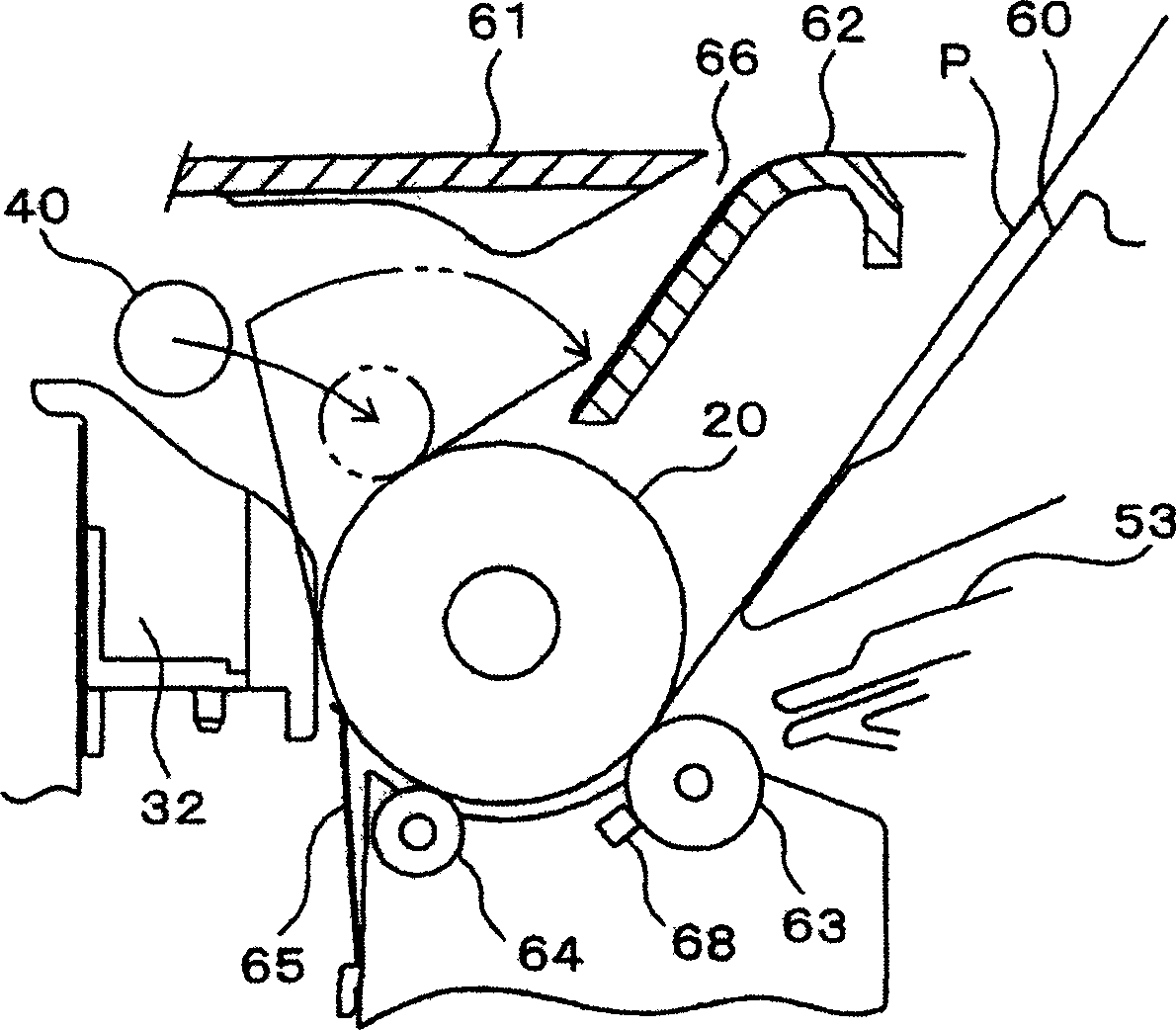

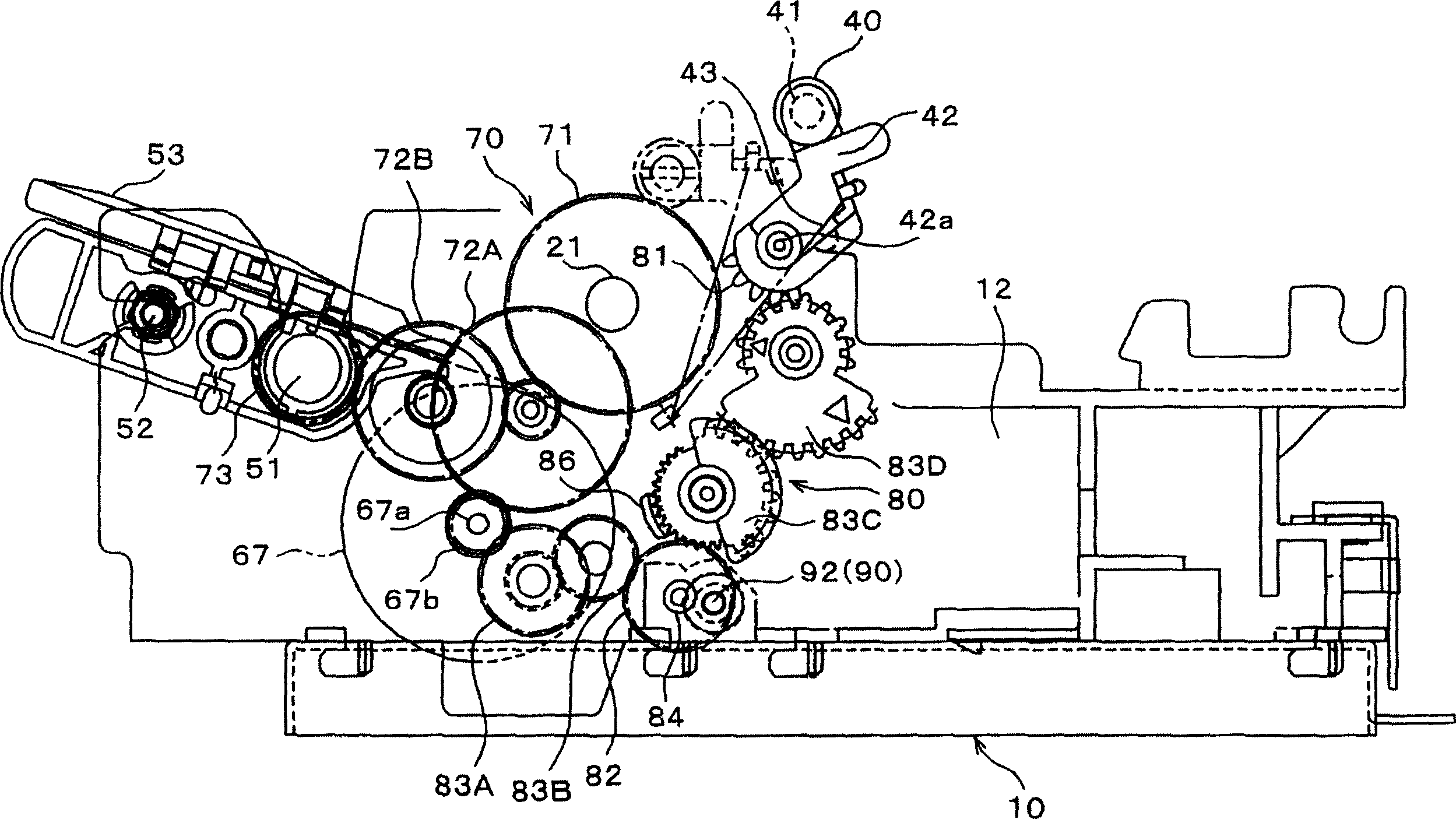

[0029] figure 1 Shows the whole state of the dot-pension printer 1 according to one embodiment in a state where the packaging components are removed, and the numeral 10 in the figure indicates that the bottom plate 11, the left side wall 12, the right side wall 13, and the back plate 14 are integrally formed. frame. A drum-shaped platen 20 is rotatably supported on the left and right side walls 12 and 13 via a platen shaft 21 , and a bracket support 30 parallel to the platen shaft 21 is supported on the platen shaft 21 . the rear of the reel 20.

[0030] The bracket 31 is supported on the bracket support 30 along the bracket support 30 to reciprocate freely. A print head 32 with needles is placed on the carriage 31 , and further, paper clips 33 are installed on both sides of the print head 32 . The carriage 31 is driven by a belt-driven drive mechanism. This driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com