Main frame split rollers rotatably supporting compaction working machines

A technology of compaction work and main frame, applied in the direction of roads, road repair, roads, etc., can solve problems such as poor compaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

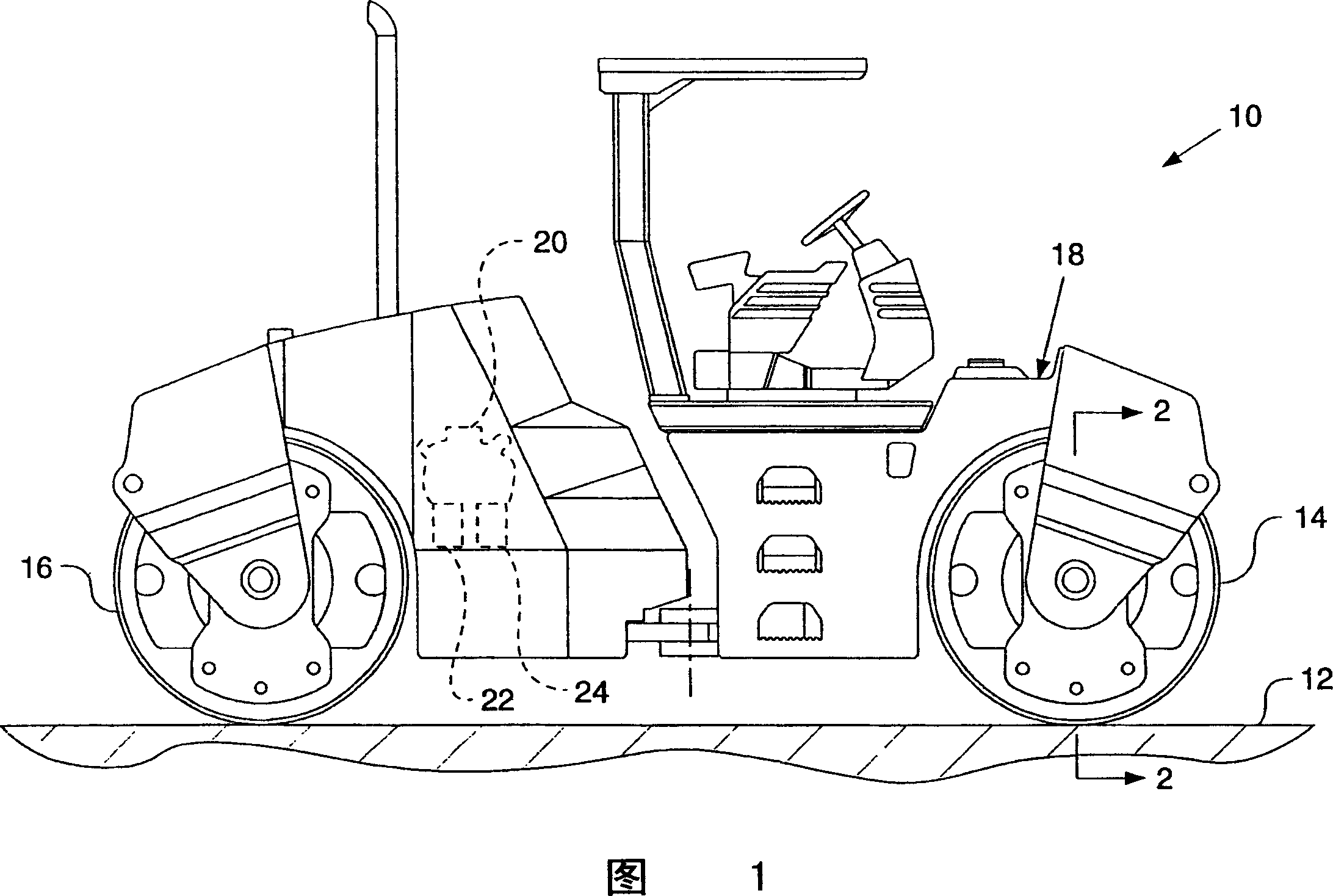

[0010] figure 1 A work machine 10 is shown for increasing the density of a compactable material or mat such as dirt, gravel, or asphalt mix. The work machine 10 is a dual roller vibratory compactor having a first / front compacting roller 14 and a second / rear compacting roller 16 rotatably mounted on a main frame 18 . The main frame 18 also supports an engine 20 having at least one power source 22, 24 and connected to the frame in conventional manner. Variable displacement fluid pumps or generators may be used as interchangeable alternatives for power sources 22, 24 without departing from the invention.

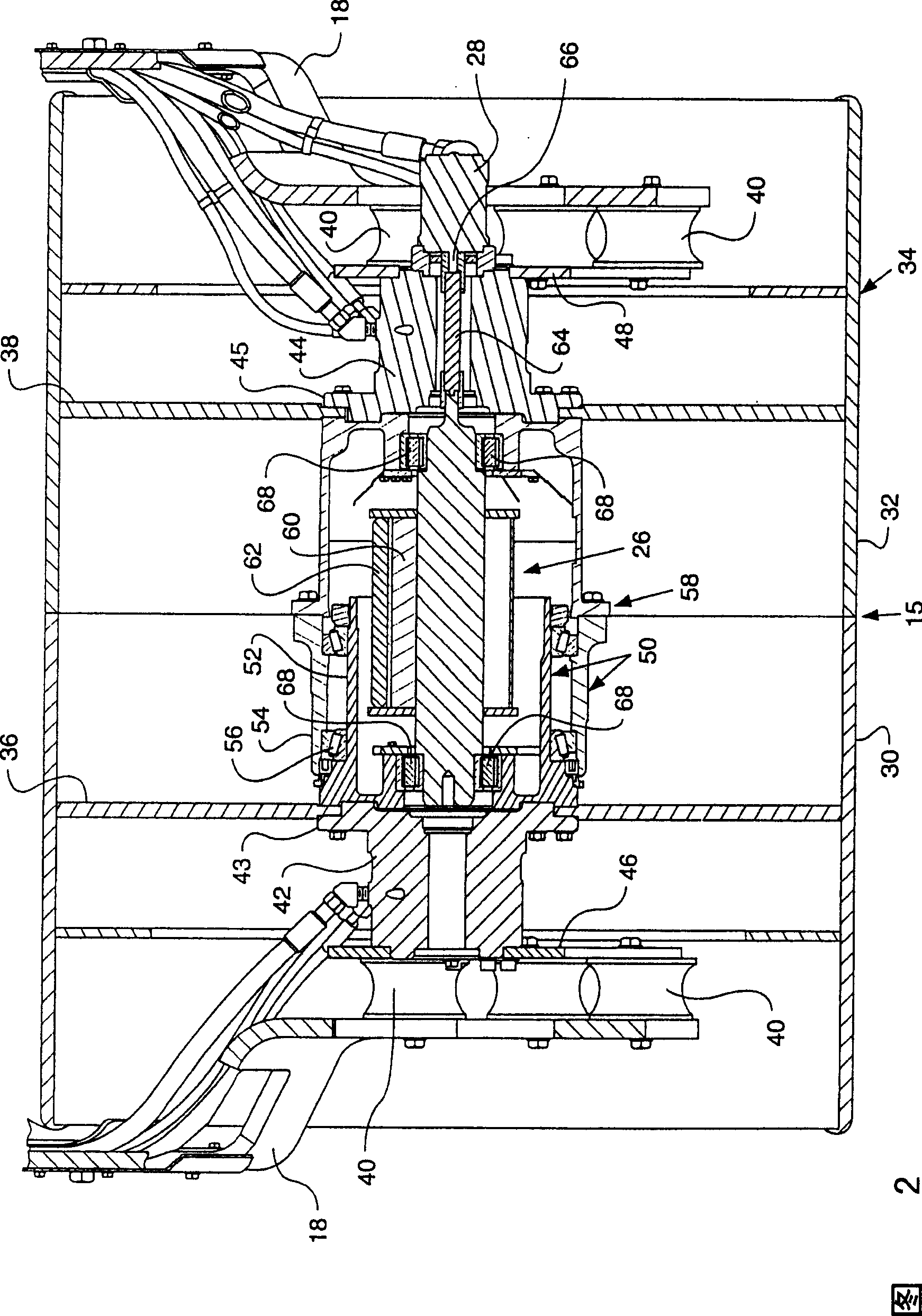

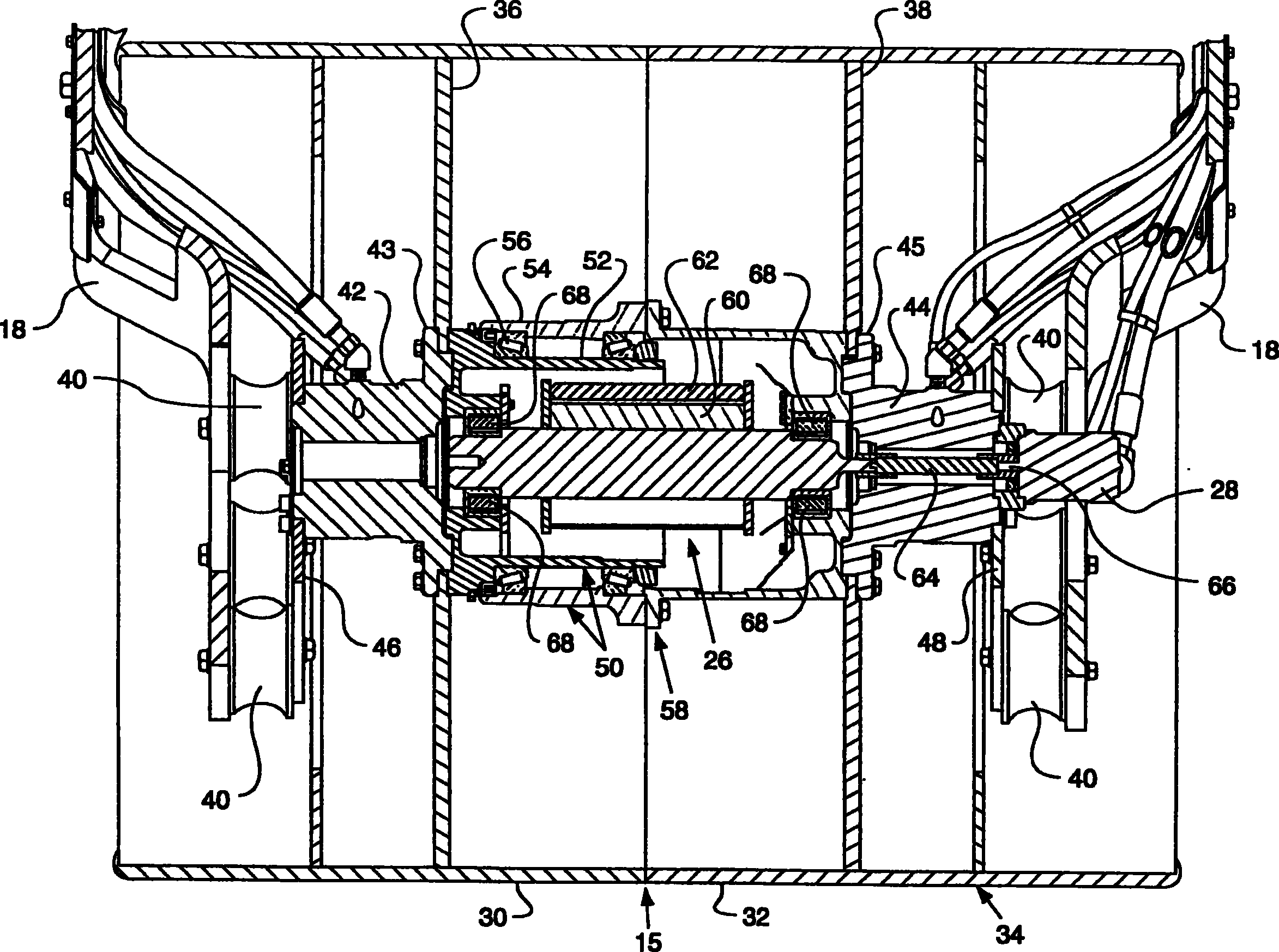

[0011] That being the case, the construction and operation of the front roller 14 and rear roller 16 are identical. The description, structure and elements including the front roller 14 will now be discussed in detail, which apply equally to the rear roller 16 . refer to figure 2 , the front roller 14 includes a vibration mechanism 26 operatively connected to a vibration m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com