Machine tool cutter automatic replacing device

A technology for automatic replacement of machine tools, applied in the field of machine tools, can solve the problems of long tool change time, high cost, inability to perform high-speed rotation positioning of heavy tools, and achieve the effect of improving working space and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

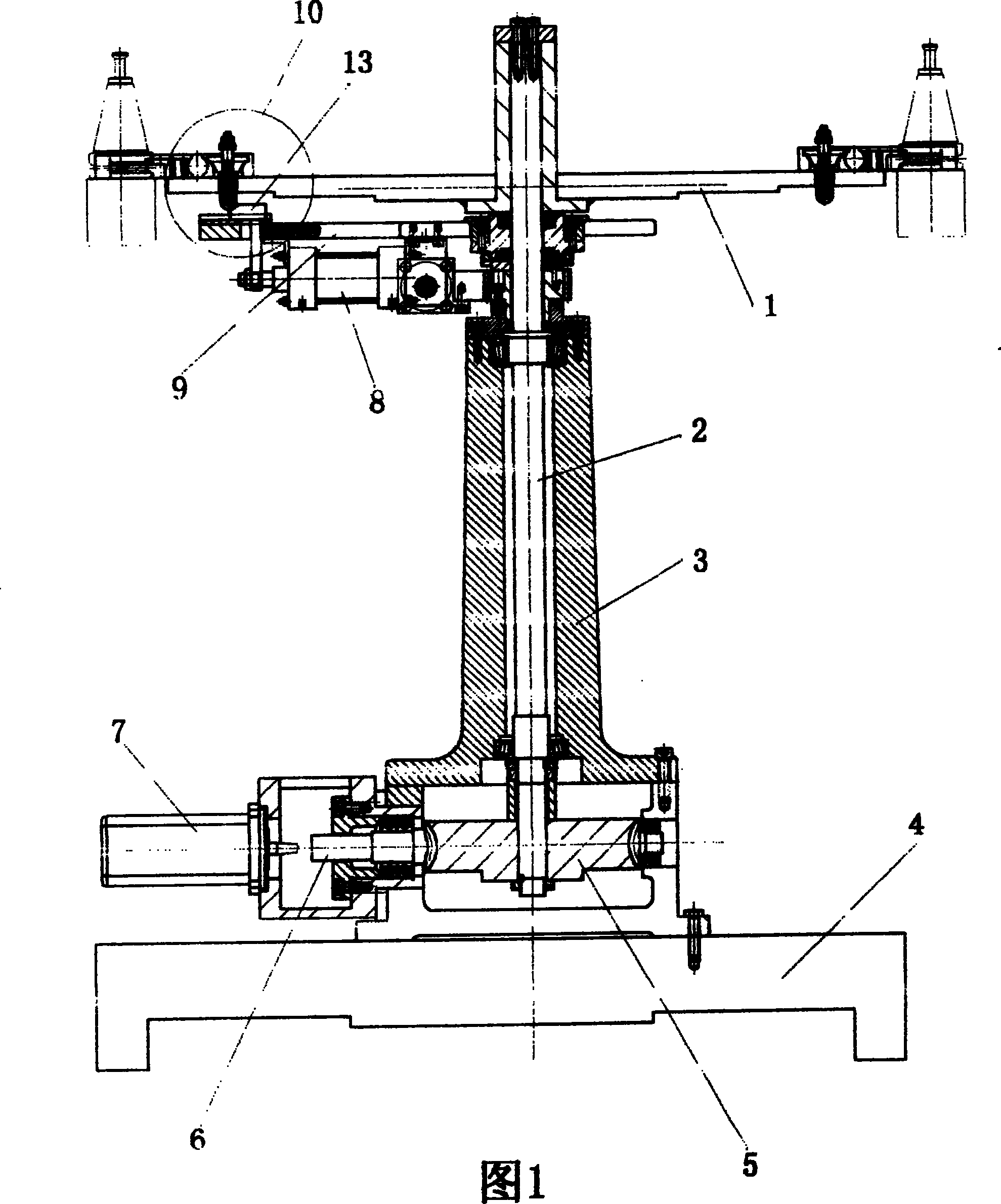

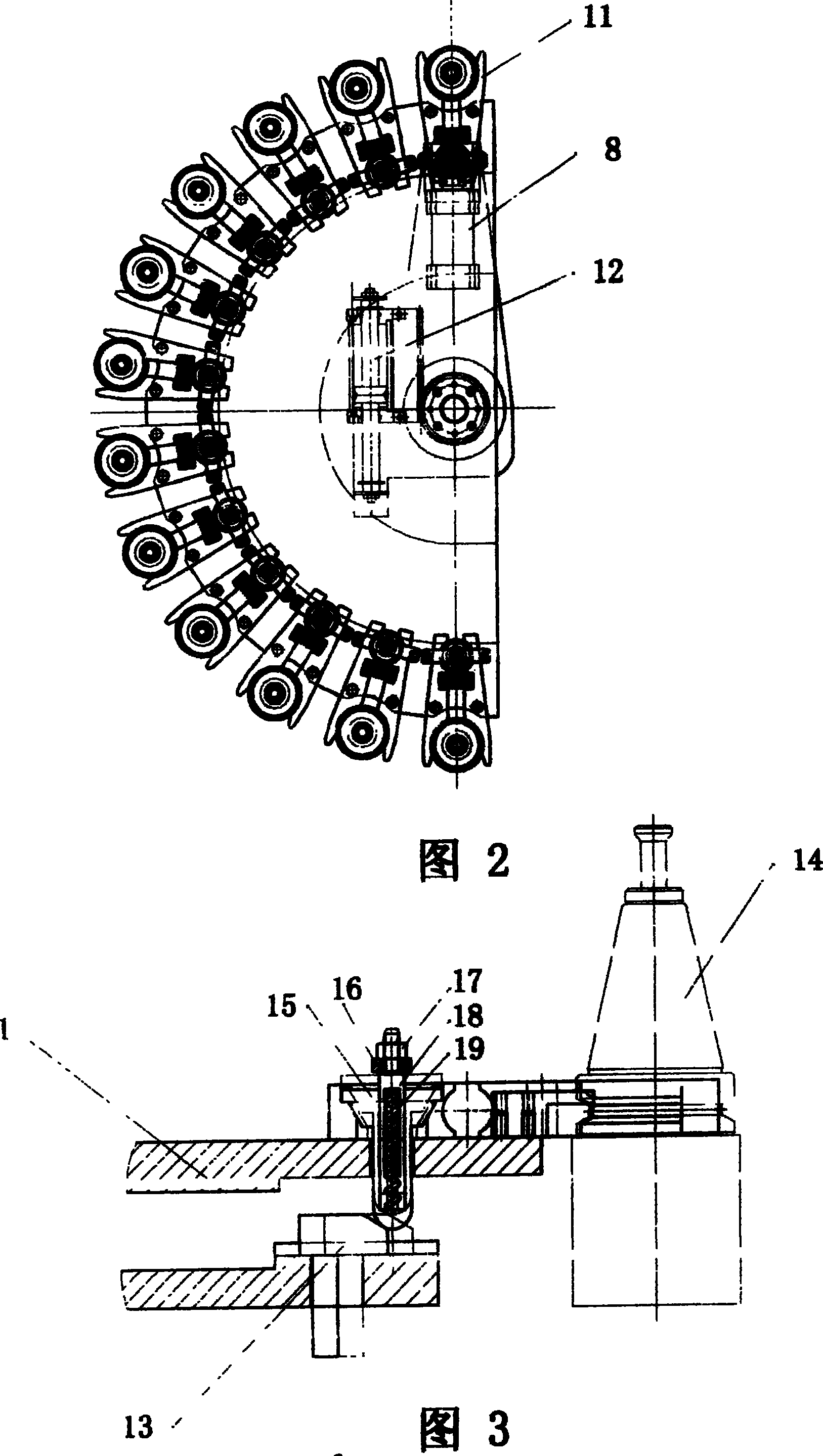

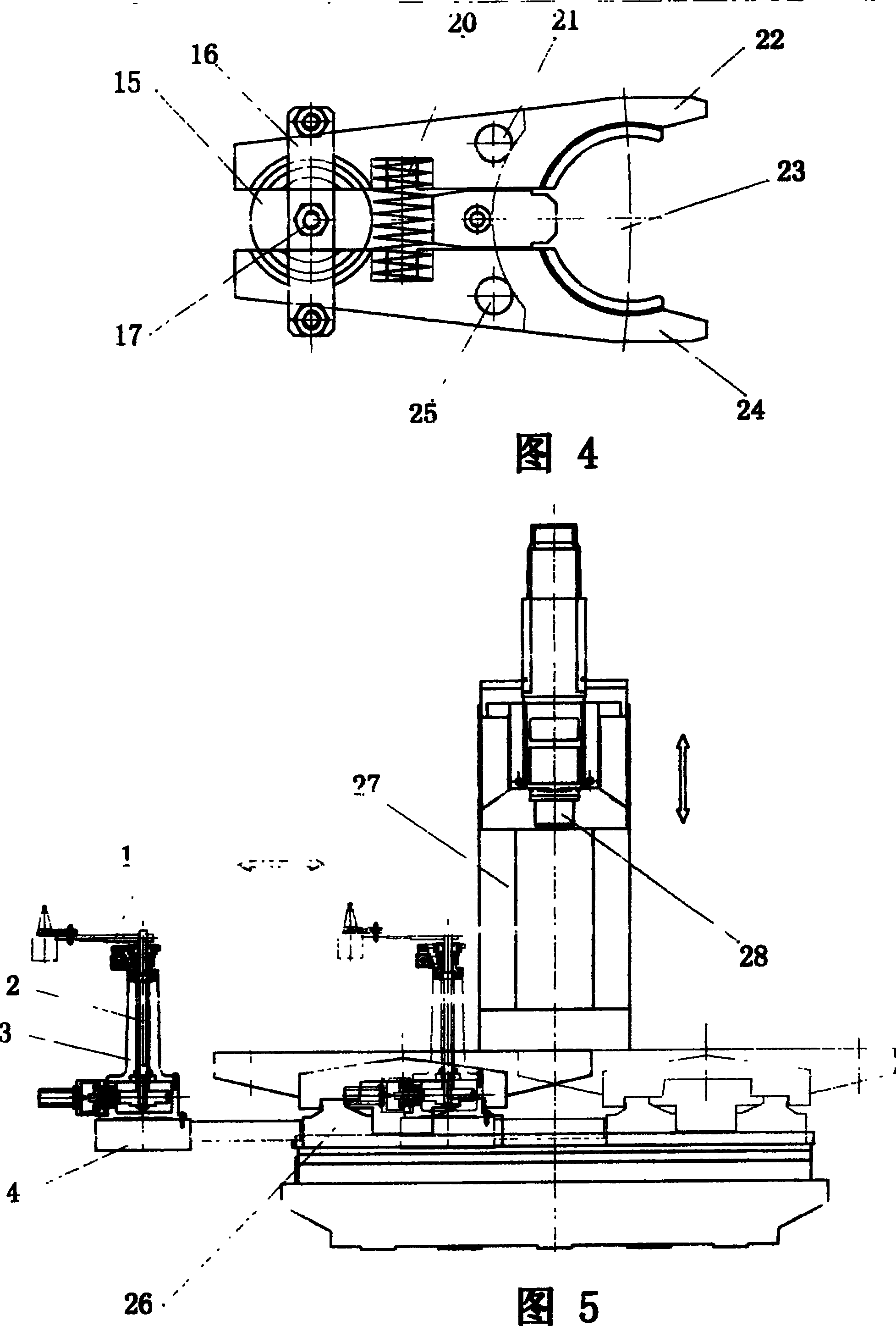

[0017] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Among them, the tool magazine base 4 and the saddle 26 move synchronously along the X direction of the machine tool. The tool magazine support 3 is vertically fixed on the tool magazine base 4, and the inner cavity sleeve in the axial direction of the tool magazine support 3 is inserted with a rotating shaft 2. The lower end of 2 meshes with the worm 6 through the worm gear 5, the worm 6 is driven by the servo motor 7, the upper end of the rotating shaft 2 is fixed with the center of the cutter head 1, the cutter head 1 can rotate with the rotating shaft 2, and the included angle of the cutter head 1 is 180-degree fan-shaped disk, the cutter head 1 of the present invention can also be a fan-shaped disk with an included angle of 210 degrees, 240 degrees, and 270 degrees. Clamps 11 are evenly distributed. The clamp 11 is composed of a left jaw 22 and a right jaw 24. The left jaw 22 and the right jaw 24 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com