Automatic set for changing tools in use for machine

An automatic tool replacement technology, applied in the field of machine tools, can solve the problems that must be installed on another device, the overall weight is increased, and the tool replacement speed is not very fast, and the effect of avoiding adverse effects and simple structure is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

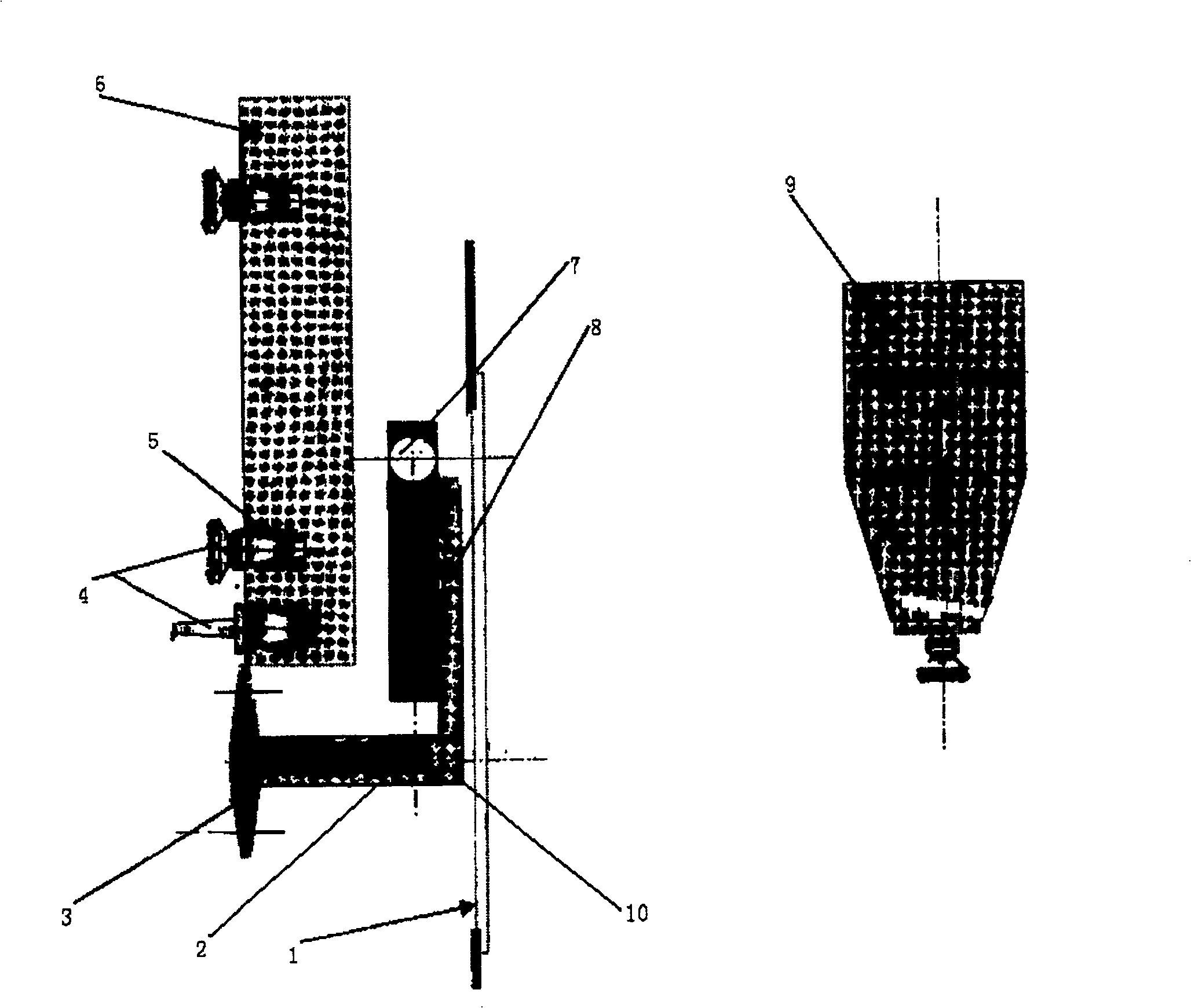

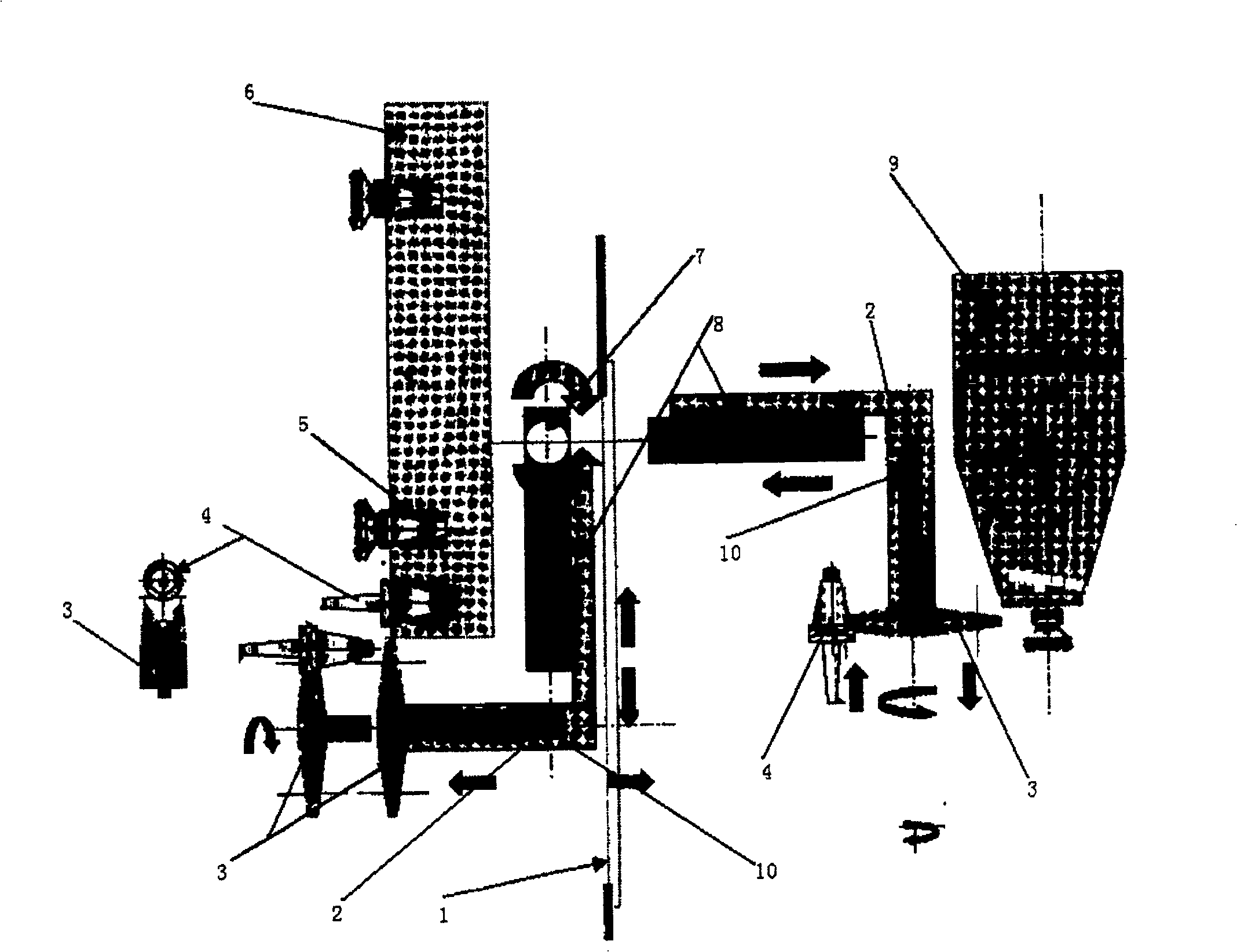

[0012] exist figure 1 Among them, the tool cutter head 6 can rotate around its own rotating shaft. The rotating shaft of the tool cutter head 6 is perpendicular to the machine tool spindle 9. The axis of the machine tool spindle 9 is parallel to the disk surface of the tool cutter head 6. The storage hole 5 of the storage tool 4, between the tool cutter head 6 and the machine tool spindle 9, a rotary shaft 7 is installed near the inner surface of the tool cutter head 6, the rotary shaft 7 is perpendicular to the rotating shaft of the tool cutter head 6 and the machine tool spindle 9, and Parallel to the disk surface of the tool cutter head 6, the rotary shaft 7 is hinged with the upper end of the telescopic rod 8, that is, the telescopic rod 8 can rotate around the rotary shaft 7, and the length of the telescopic rod 8 can be elongated or shortened as required, and the lower end of the telescopic rod 8 It is fixed together with the right end of the pole 2, the pole 2 is perpen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com