Emergency stop system of elevator

An emergency, elevator technology, applied in elevators, transportation and packaging, etc., can solve the problems of increased guide rail wear and damage, shortened guide rail life, and hindering the long life of the safety braking system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

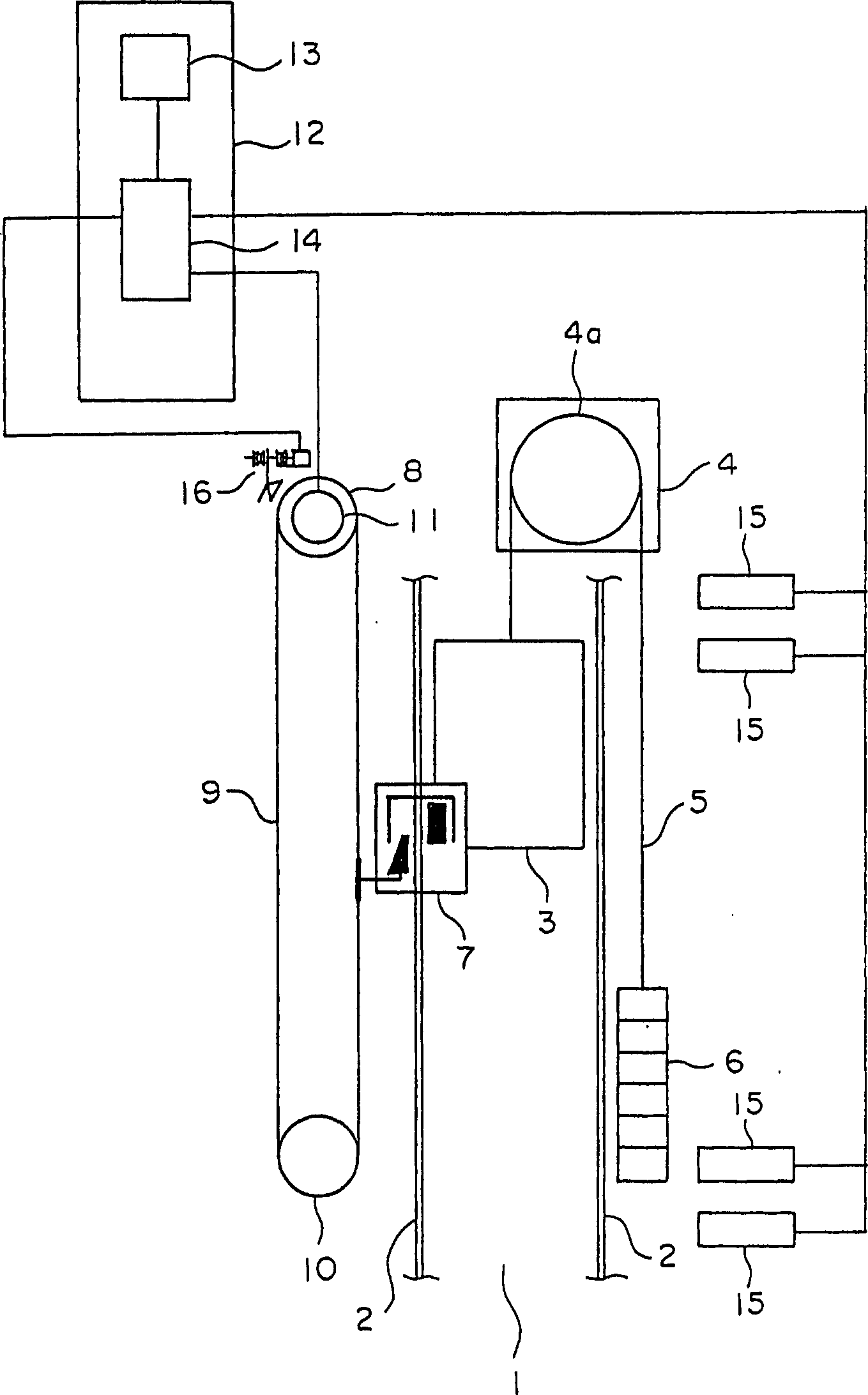

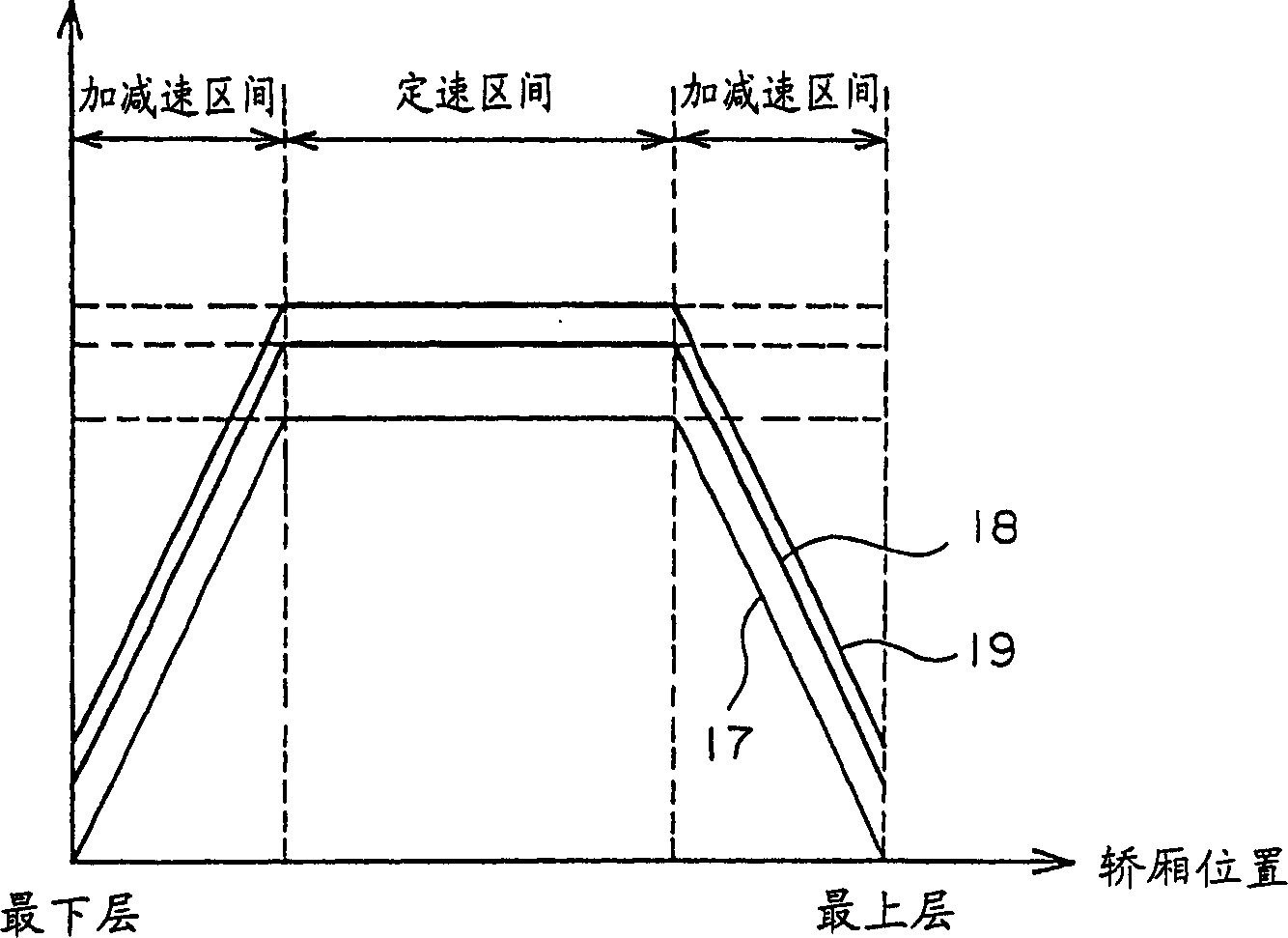

[0022] figure 1 It is a configuration diagram schematically showing the elevator apparatus according to Embodiment 1 of the present invention. In the drawing, a pair of car guide rails 2 is provided in a hoistway 1 . The car 3 is guided by the car guide rail 2 to move up and down in the hoistway 1 . At the upper end of the hoistway 1, a traction machine 4 serving as a driving device for raising and lowering the car 3 and the counterweight 6 is disposed. The main rope 5 is wound around the drive sheave 4a of the hoisting machine 4 . The car 3 and the counterweight 6 are suspended in the hoistway 1 by the main rope 5 . The hoisting machine 4 is provided with a brake device (not shown) that brakes the rotation of the drive sheave 4a.

[0023] On the car 3, a pair of emergency stop devices (braking parts) 7 interlocked with each other are attached so as to face the respective car guide rails 2 . Each emergency stop device 7 is arranged at the lower part of the car 3 . The ca...

Embodiment approach 2

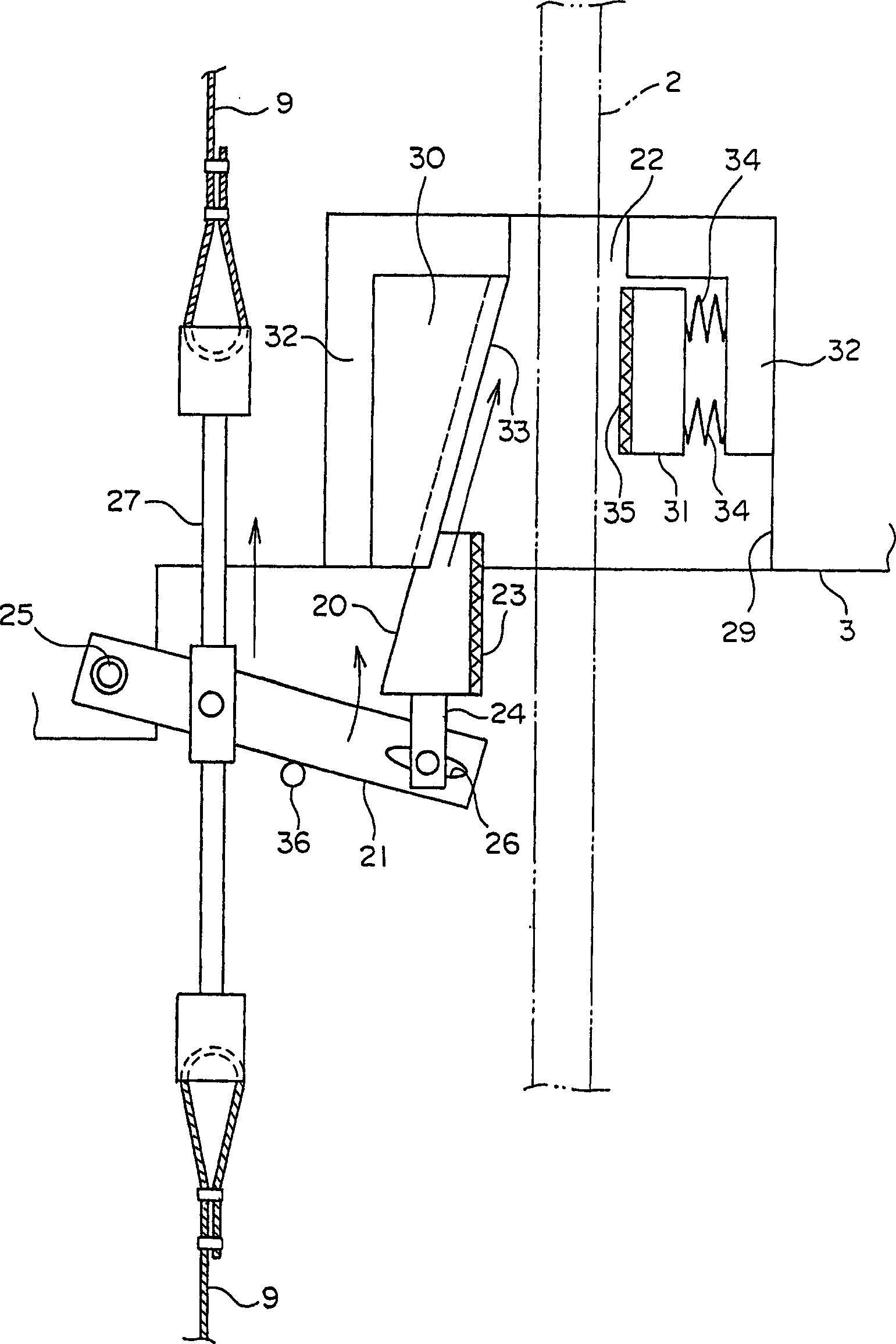

[0073] Figure 7 is a front view schematically showing an emergency stop device of an elevator emergency stop system according to Embodiment 2 of the present invention, Figure 8 yes means Figure 7 Side view of the emergency stop device in . In Embodiment 1, in order to brake the car 3, the car guide rail 2 is clamped by the wedge 20 and the pressing member 31, but as shown in the figure, the car guide rail 2 may be clamped by a pair of wedges 20. 2.

[0074] In the figure, each emergency stop device 7 comprises: a pair of wedges 20; Link mechanism 71, when it passes car 3 descends to the restraint of overspeed governor rope 9, makes each wedge 20 move relative to car 3; As The jaw member 72 of the guide portion guides each wedge 20 moved by the link mechanism 71 in a direction in which it comes into contact with the car guide rail 2 .

[0075] The link mechanism 71 includes: a connecting plate 73, one end of which is connected with the upper tie rod 27 in a rotatable man...

Embodiment approach 3

[0085] Figure 10 It is a configuration diagram showing a rope clamping device of an elevator emergency stop system according to Embodiment 3 of the present invention. In the figure, an electromagnetic actuator 81 is mounted on the mounting member 45 . The electromagnetic actuator 81 includes: a movable part 82, which can move between the working position where the brake shoe 42 is pressed to constrain the speed governor rope 9 and the release position where the restriction to the speed governor rope 9 is released; The pressing spring 83 applies force to the movable part 82 to the working position; the electromagnet 84 resists the biasing force of the pressing spring 83 to move the movable part 82 to the release position. The electromagnet 84 is mounted on the horizontal portion 46 .

[0086] The movable part 82 includes: a movable plate 85 attracted by the electromagnet 84 by energizing the electromagnet 84; and a movable rod 86 fixed on the movable plate 85 and penetrating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com