15.Roll combined straightening machine

A straightening machine and straightening technology, which is applied in the field of metal strip straightening, can solve the problems of poor straightening quality of thin-gauge products, low reduction precision, and difficult straightening process of thick-gauge products, so as to achieve easy maintenance, The effect of improving quality and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

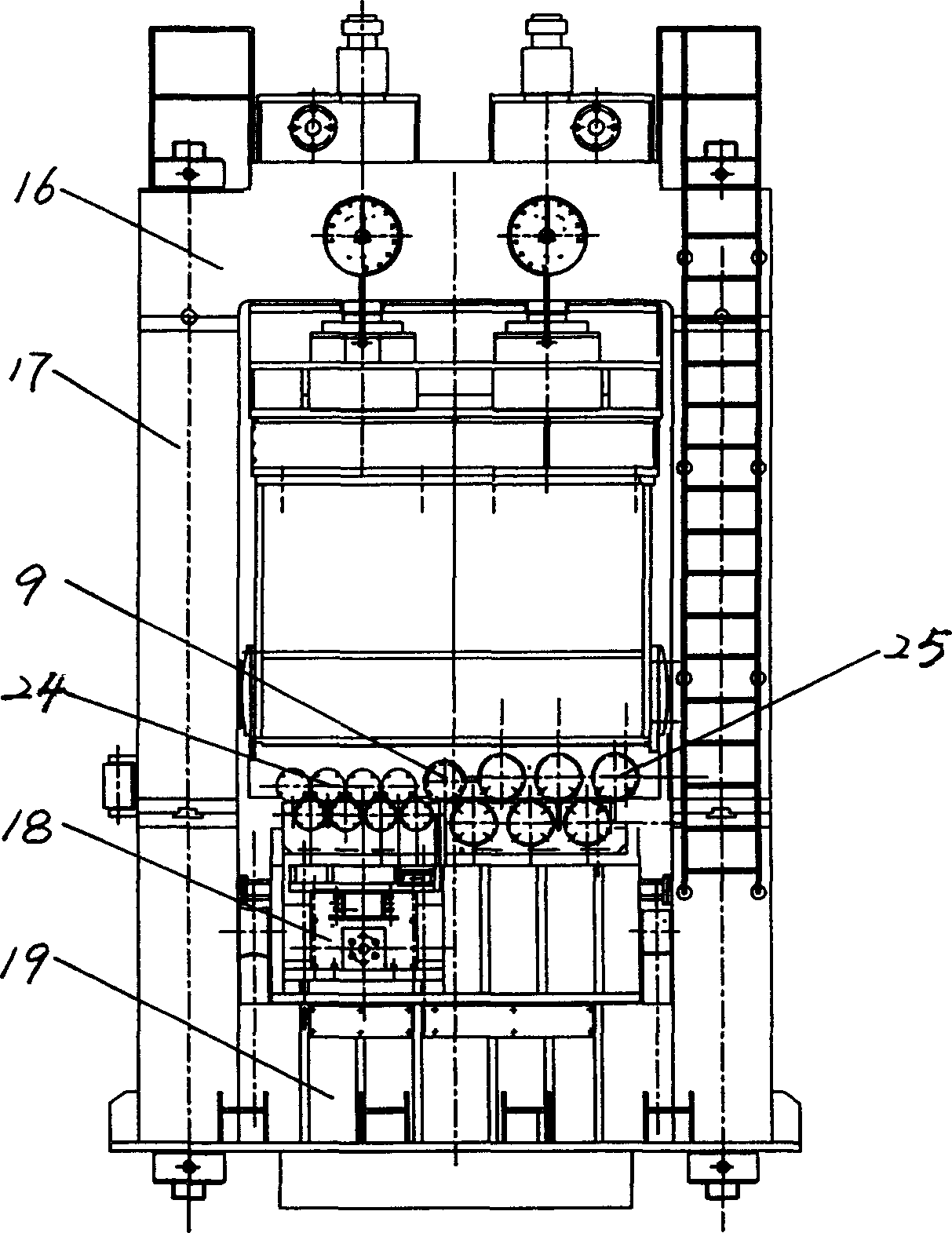

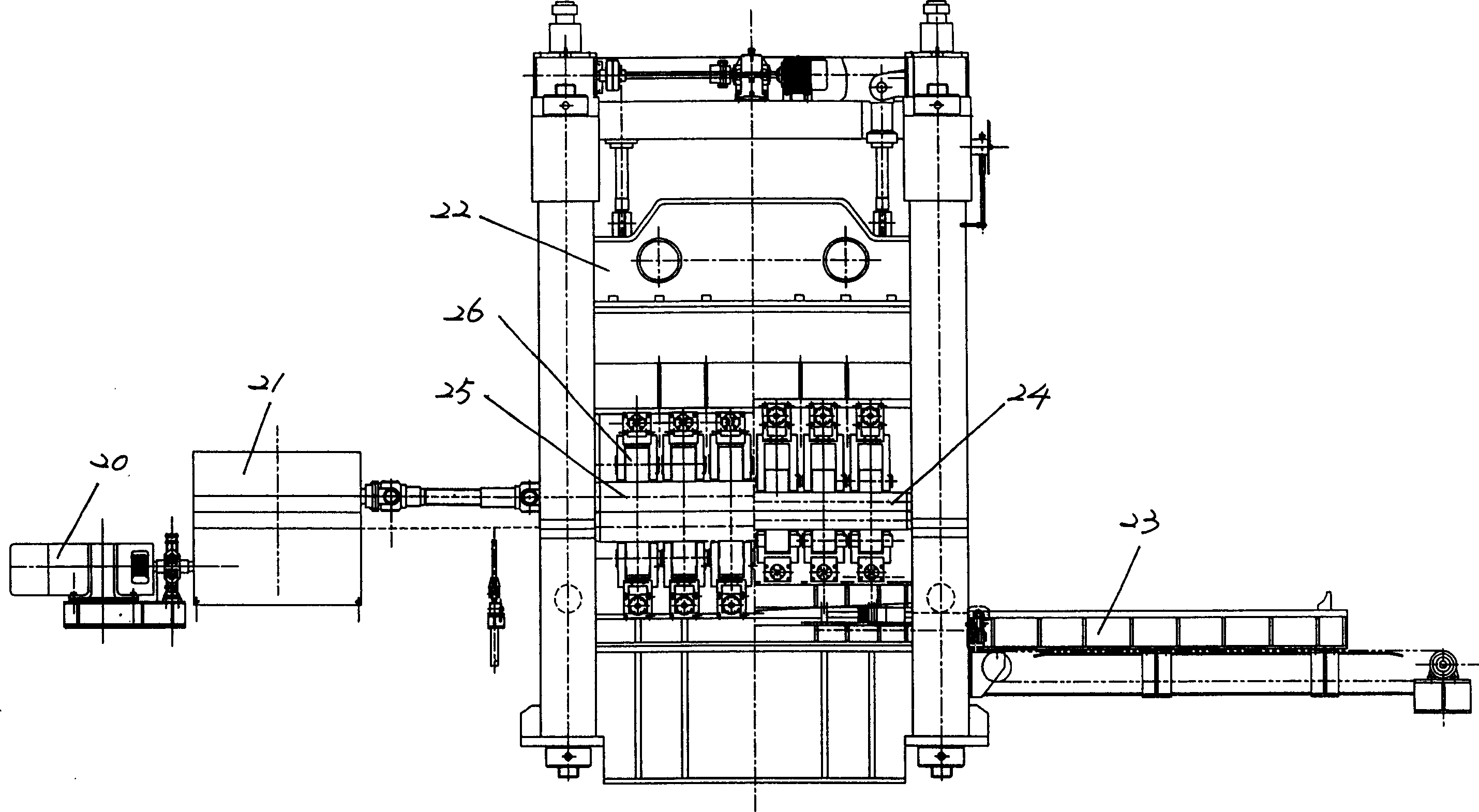

[0039] The embodiments of the present invention will be further described in conjunction with the accompanying drawings. This embodiment is used to illustrate the present invention, but not to limit the present invention in any way.

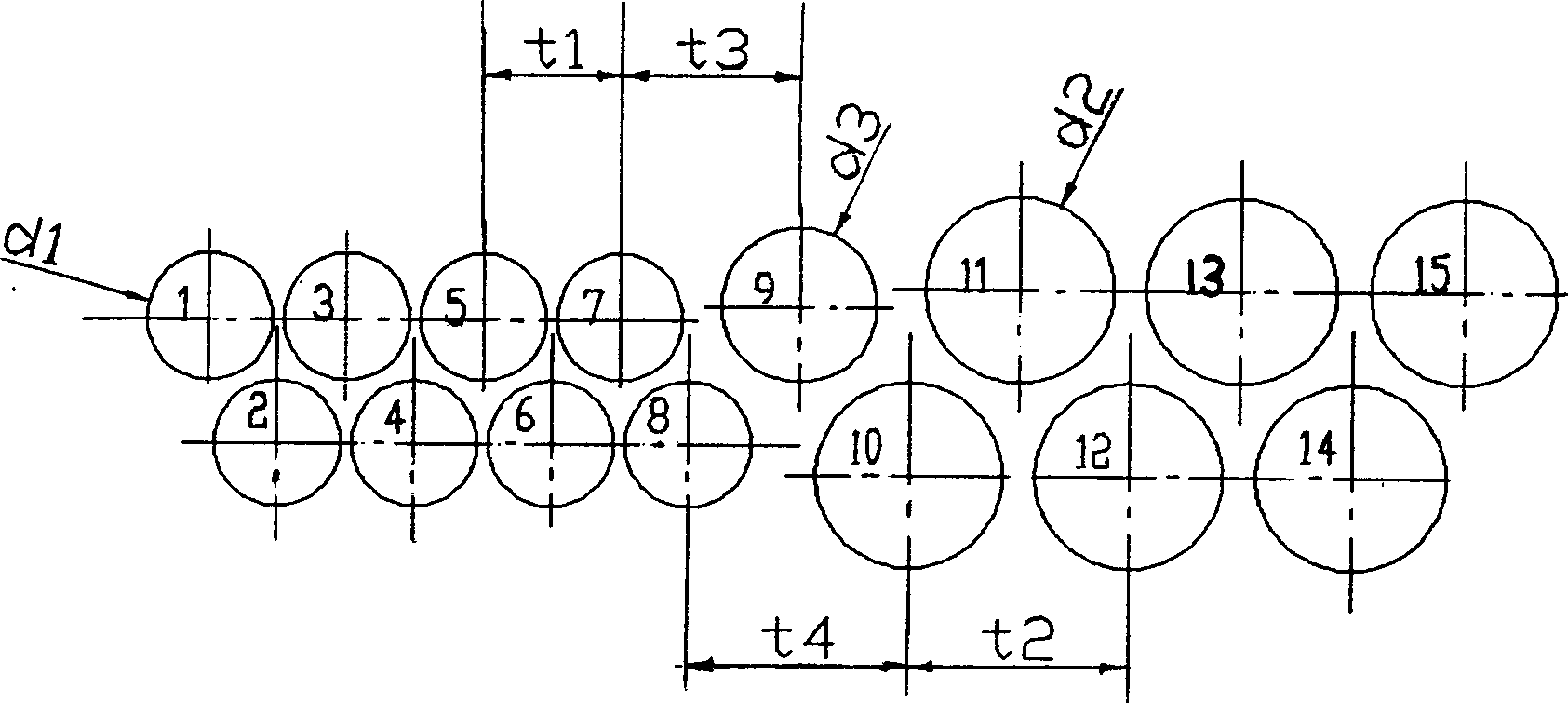

[0040] The straightening machine based on the present invention has completed overall design, and its roller system parameter setting is d1=230mm, t1=250mm, d2=340mm, t2=400mm, d3=280mm, t3=325mm, t4=400mm.

[0041] The thickness range of straightened products is 6-40mm, the straightened strength range is σs≤600Mpa, and the straightened width range is 1500-3000mm. When the product thickness is less than or equal to 20mm, use 15 rollers for straightening, and when the product thickness is greater than or equal to 20mm, use 7 rollers for straightening.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com